Smart Solutions for Age-Old Problems; New Ways to Reduce Scrap, Improve Production

Even though laser-cutting systems have become more efficient with greater power levels, the industry faces some of the same problems.

Posted: April 29, 2024

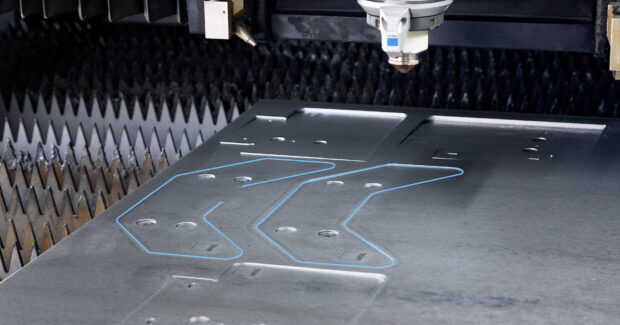

The 1-micron solid state laser has dominated the laser cutting world for the last decade. Solid-state laser cutting machines challenged the CO2 machines of the past, offering greater wall-plug efficiencies, less involved maintenance schedules, and higher throughput thanks to the laser source itself. These benefits were so apparent that the industry shifted its sights. Nowadays, the 1-micron solid state laser is the source of choice for manufacturers on every continent.

Even though laser-cutting systems have become more efficient and have greater power levels than in the past, we still find ourselves facing some of the same problems. These evergreen topics include machine setup issues, material variations, maximizing material utilization, and the need to produce parts autonomously. Fortunately, machine manufacturers are developing the next generation of technology to help address these issues and reduce the impact they will have on your production.

Avoiding Scrapped Parts and Not Holding up Production

In a busy shop, an operator will have responsibilities revolving around the laser cutting operation, which could include sorting parts, disposing of scrap material, and keeping the machine fed with raw sheets. While the operator is handling all of these tasks, sometimes an issue with how the machine is cutting or how the programmer sets up the nest can go unnoticed for a while. Such issues can also arise during an unmanned shift, and a machine can end up cutting scrap parts or cause a “feed hold” pause. This problem is one that TRUMPF has addressed with a system called Smart Rerun. The concept of the system is that when a cutting flaw or nozzle collision is detected by the machine, Smart Rerun will be activated. Then, the system will go back in the program to before it encountered an issue and initiate a recut, without an operator having to intervene with the machine. This ultimately saves the part rather than having to scrap it or cut a new part during a post-production process. It also allows for a greater rate of success when the machine is left to produce parts alone in a “lights out” production situation.

Maintaining High Process Stability and Productivity

In addition to reducing scrap parts, another perennial challenge is minimizing unplanned downtime. This age-old problem is created by varying material qualities, which come in the form of thickness variations, material surface condition and composition. The usual way of tackling such issues is to have the operator make laser parameter adjustments that (hopefully) get the laser machine to cut the material properly. However, this traditional approach can cost valuable production time, potentially requiring parts to be scrapped, and even then, you may not have the most optimized parameter. New technology liberates the operator from having to adjust laser parameters due to these types of variations, freeing up that time for other more important tasks. So how does it work? TRUMPF’s Active Speed Control monitors the kerf as the machine is cutting, allowing for proactive and automatic adjustment to the laser parameters while keeping the process stable and the productivity for the material high. With this system, the machine has the ability to actively make changes during the cutting process. This means that if material properties change, the machine will adapt to them on-the-fly, without requiring operator input. The technology also keeps an eye on the beam centering, so that if there is an issue, the operator can act swiftly. If a problem occurs, a message will prompt the operator to make an adjustment; without the need for a tape shot.

Greater Reliability and Material Utilization

So far, we have looked at ways that laser cutting machines can adapt to material and setup issues, but how do we get more out of each piece of sheet metal we are using? In the past, the way to get more material utilization, as well as ensure a more reliable nest, was to use a micro tab or micro joint. A micro tab, or micro joint, is a small “tab” of material that joins the scrap skeleton or slug to the part. This micro tab allows for tighter nesting and more reliable processing, but it leads to increased de-nesting time and often requires post-processing of the part to get rid of the leftover micro tab. Instead, new technology enables nano joints. The goal of a nano joint is the same as the micro tab — hold the part in place for reliable processing and enable the parts to be nested efficiently for maximum material usage – but the method of producing the tab is different. Instead of a code-based “stop and start” process that leaves a tab as thick as the material, the laser source itself is utilized. The laser power is ramped up in a way that the cutting process remains stable, but a small “missed cut” is created near the bottom of the material. This nano joint holds the scrap to the part or the part to the skeleton, leaving the operator with a part that is easy to remove and a highly stable nest. In turn, the programmer can now nest parts together more closely or to utilize a common line cut strategy that might have been deemed too unstable for a micro tab. The side edge is also left clean, without the need for post-processing, because the tab that is created is nearly flush with the cut edge.

In short, new technologies show us what the future of laser processing looks like. Alongside the high laser powers and automation systems, smart solutions that can tackle the more intricate problems we deal with on a day-to-day basis are just as important to helping manufacturers achieve greater success in this industry.