Advanced Parting at a 90° Angle

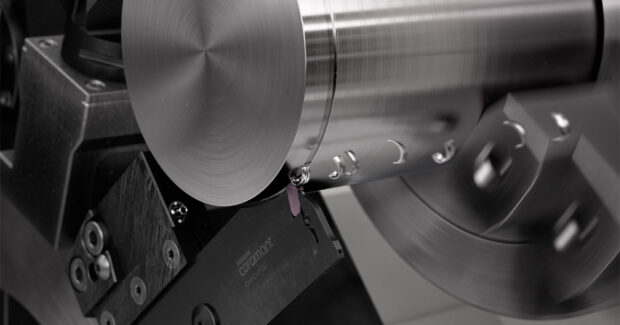

Sandvik Coromant announces CoroCut QD for Y-axis parting, which improves surface quality, and creates less vibration compared to conventional parting off, resulting in less noise.

Posted: April 10, 2024

Metal-cutting tool specialist Sandvik Coromant has upgraded its CoroCut® QD Y-axis parting tools. With greater performance and ease of use, the CoroCut QD Y-axis tools are optimized to enable improved surface quality, reduced vibration and higher blade stiffness.

Unlike conventional parting-off tools that align with the X-axis of the machine tool, Y-axis parting operates on a different principle by rotating the insert pocket 90 degrees and aligning it with the Y-axis, providing several benefits.

The upgrade to the CoroCut QD improves surface quality, creates less vibration compared to conventional parting off — resulting in less noise — and allows for the parting off of much larger diameters than what is currently possible with conventional methods. Additionally, shifting the resultant load to the strongest section of the blade creates six times higher blade stiffness, enabling increased feed and longer overhangs without losing stability.

More specifically, the blades have been upgraded to have no Y offset, meaning easier programming and increased stroke. The blades also have a stop surface that serves two important application needs — preventing the blade from being pushed into the adaptor and enabling easier setup.

“Conventional parting off uses feed motion along the X-axis, which means the cutting force is directed through the weakest section of the blade,” said Fredrik Selin, Global Product Application Specialist in Turning. “This can lead to deformation and instability. By rotating the insert pocket 90 degrees and using the Y-axis, the cutting force is shifted down through the complete blade length, resulting in an increased blade stiffness of up to 600 percent.”

“CoroCut QD is ideal for parting off in turning centers and multitask machines with Y-axis,” continued Selin. “This includes parting off in sliding head machines, large diameters of up to 120 millimeters (mm), and long overhangs to reach between main and sub chuck. So, when there is the need to part off or machine deep grooves without compromising process security or machining efficiency, the upgraded CoroCut® QD solution is the perfect choice.”

CoroCut® QD product range

About Sandvik Coromant

Together with our customers and partners, Sandvik Coromant leads the way toward a sustainable future, supplying tooling solutions to the world’s engineering industries. Over eight decades of hands-on experience have given us a wealth of knowledge in metal-cutting and machining. This expertise transforms every challenge into an opportunity for innovation, collaboration and progressive solutions. We aim to create positive change by promoting sustainability, efficiency and growth to shape a future where innovation thrives. Part of global industrial engineering group Sandvik, Sandvik Coromant is shaping the future together.