Stay on Top with Dynamic, Pioneering and Agile Cutting Systems

Investing in cutting systems driven by advanced automation capabilities and intuitive controls is a strategic move for fabricators looking to boost performance, manage waste and reduce costs. Laser Cutting Machine Outperforms Higher Wattage Lasers at Lower Operating Cost AMADA AMERICA…

Posted: February 16, 2024

Investing in cutting systems driven by advanced automation capabilities and intuitive controls is a strategic move for fabricators looking to boost performance, manage waste and reduce costs.

Laser Cutting Machine Outperforms Higher Wattage Lasers at Lower Operating Cost

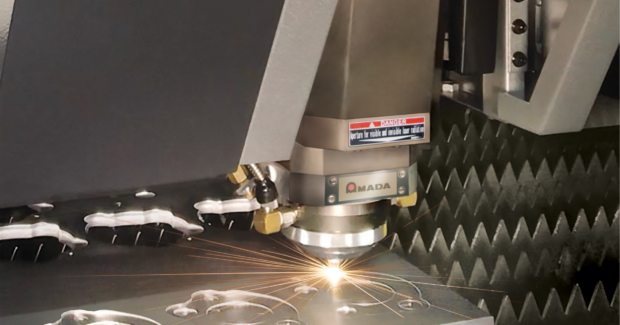

AMADA AMERICA INC.’s (Buena Park, CA) Ventis 3015 AJe is a 6kW fiber laser cutting system with Locus Beam Control (LBC) technology that provides the same performance as higher wattage lasers with less power consumption. The machine features LBC monitoring, nozzle change/centering and laser head collision recovery. The AMNC 4ie control provides easy, efficient operation for operators of all skill levels. The flexible beam shape control provides high-quality cutting on stainless steel and aluminum. Kerf control ensures easy part removal from thicker materials.

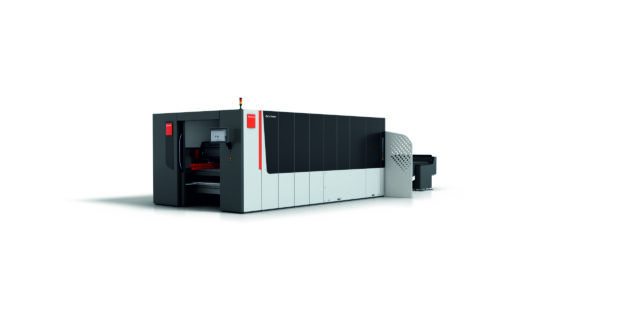

Smart Access to Fiber Laser Technology

Bystronic Inc.’s (Hoffman Estates, IL) enormously flexible ByCut Smart 3015 cuts steel, aluminum, stainless steel, brass, and copper precisely and reliably, thanks to high laser power with three-to-15 kilowatts, an optimized cutting process, and smart features — all at an attractive price. The ByCut Smart is flexible due to its maximum degree of configurability. Smart features such as the Nozzle Control Tool and KerfScan, the Parameter Wizard, and cutting with MixGas, in addition to more laser power, ensure higher cut quality as well as increased productivity.

With the new shuttle table concept, users load their ByCut Smart up to 40 mm over the entire surface on both tables, or 60 mm over the entire surface on one table. Operators achieve a significantly higher maximum load on the shuttle table compared to the status quo of 30 mm and can cut significantly thicker parts.

In addition, the new ByCut Smart design significantly increases user friendliness. Different access door configurations provide flexibility in the design. This includes front and/or side access as well as multiple windows with direct views of the cutting process. Overall, the new design offers better access to the interior space as a result. What’s more, Bystronic’s software and automation solutions optimally integrate the ByCut Smart into your sheet metal production.

Light-industrial CNC Plasma System Achieves Milestone

Swift-Cut, (North Bethesda, MD) manufacturers of affordable CNC plasma and waterjet cutting systems, celebrated a milestone in 2023 with the sale of its 4,000th Pro series machine. The Pro series combines high-precision and good cutting speeds on material up to 25 mm (1 in.). Swift-Cut offers four table sizes, ideal for smaller spaces, in its Pro series range: 1250-x-1250 mm (4’-x-4’), 2500-x-1250 mm (8’-x-4’), 3000-x-1500 mm (10’-x-5’) and 4000-x-2000 mm (13’-x-6.5’). Systems are available with ESAB and alternative power sources for air-plasma cutting at up to 125A. Swift-Cut’s easy-to-use software guarantees that anyone with a basic knowledge of computers can operate the CNC cutting system.

Machines arrive fully assembled, simplifying installation, and training is included as standard. The software features a built-in parts shape library, can import DXF/DWG files or convert JPG images for cutting, has automatic part nesting (optional) to optimize plate use/reduce scrap and a plate alignment function that eliminates the need to reposition a misaligned plate on the cutting bed. In-house technicians with access to remote support software, plus a custom mobile app, mean in the unlikely event of an issue, downtime is kept to a minimum.

Waterjet System Boasts Capabilities Typically Found in Elite Systems

The Flow Waterjet’s (Kent, WA) Mach 200c is a cutting-edge, best-in-class 5 axis cutting system that delivers unparalleled speed and precision at a value-focused price point. Featuring Pivot+™ waterjet technology, the Mach 200c enables bevel and 5-axis cutting of virtually any material, hard or soft, with up to 60° of motion, and boasts faster, more accurate cutting. Its high-speed motors and drives allow for rapid speed and acceleration/deceleration ultimately providing faster overall cut time. Additionally, the system features an easy load/unload table and a bridge that is canted back to allow for full table access.

High Productivity and Low Operating Costs Result in Success of Plasma Cutter

Hypertherm Associates (Hanover, NH), a manufacturer of industrial cutting systems and software, announced earlier this year that is has completed the assembly of its 10,000th MAXPRO200 System, and credits this milestone to thousands of manufacturers and fabricators worldwide who depend on it.

“We built a plasma cutter that delivers high productivity with low operating costs,” said Tyler Kipp, marketing program manager. “Job shops, steel centers, heavy equipment manufacturers — anyone needing solid cutting power and capacity without requiring high-definition cutting — have proven this.”

Serving thousands of customers across diverse industries and applications, Hypertherm Associates pays attention to how the economic landscape and market trends affect manufacturing and production floors of all sizes. Customer pain points are front and center as engineering considers “the right tool for the job” when designing a new machine or technology.

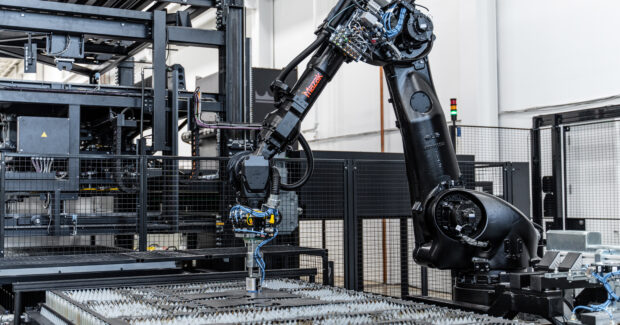

Smart Cell Robot can be Customized to Accommodate Your Shop

Mazak Optonics Corp. (Elgin, IL), a leader in the manufacture of advanced laser-cutting solutions, including CNC controls and automation systems, offers the SMART CELL. The SMART CELL is a 6-axis robot that utilizes interchangeable magnetic and suction cup grippers to sort laser-cut parts, load raw material, and remove remnant material. Magnetic heads are used to pick and place mild steel parts while the suction cup grippers are ideal for material that is not magnetic, like stainless and aluminum. SMART CELL can be customized to accommodate the needs of most shop environments. The sorting system is available in multiple sizes and payload options to sort a wide range of geometry, with the base design featuring a small 20’-x-20’ footprint. Ideal for first-time automation users, SMART CELL offers an easy-to-use interface. The robotic sorting system utilizes Mazak’s SMART SYSTEM software to identify the location of each part based on cutting data from the laser. A drag-and-drop feature simplifies programming the robot to unload laser-cut parts in specified arrangements. The software’s ease of use makes it a great solution for production environments running similar jobs and job shops running multiple parts of different nests. Compatible with Mazak’s flat sheet laser-cutting machines, SMART CELL can be integrated as a standalone solution or with automated storage towers for continuous production.

New Automated Plasma System Sets Benchmark for Performance

Thermal Dynamics Automation’s (Denton, TX) new UC Series of high-precision automated plasma power supplies features four models offering cutting power ranging from 130 up to 800A for maximum productivity, cut quality and reliability for piercing mild steel up to 2” (3.5” edge start) and stainless steel up to 4” (6.25” edge start).

“The new UC series delivers development work from the last two years to cut faster, better and smarter,” said Dirk Ott, the vice president of global plasma automation for Thermal Dynamics. “For example, two UC 201, UC 301 or UC 401 can now be connected double cutting output to 400, 600 or 800 amps, respectively, or they can operate independently. Furthermore, the QuickPierce technology dramatically improves very thick mild steel cutting performance, making the new UC series the ideal choice for heavy duty applications.”

Target applications for the paralleling capability include fabricators and steel services centers that use two torches on the same gantry and want to increase cutting speeds on steel plates up to 2” (50 mm) thick. It also lets fabricators cut stainless steel and aluminum sections up to 6.25” (160 mm) for applications in the power generation, pressure vessel, windmills, chemical and petrochemical processing industries. To double a torch’s cutting output, users need to change the SpeedLok™ consumables cartridge, which takes less than a minute.

New features include bevel wear parts, new bevel angle data, an improved XT torch head design, and a three-year warranty on the power supply.

New Innovative Nozzle Design for Laser Cutting Different Materials

Featuring speed, high-quality, and precision, TRUMPF’s (Farmington, CT) TruLaser 5000 and 3000 series laser cutting machines are designed with features to help manufacturers achieve fabricating success. Now, technological advances make the laser-cutting process even more productive, dependable and high quality. TRUMPF’s new FlexLine technology introduces an innovative nozzle design that ensures a highly reliable process when laser cutting different materials, particularly mild steel, and materials of various surface quality.

TruLaser machines are now available with 24 kW of laser-cutting power. As fabricators utilize machines with higher power levels, they can also see an increased demand for cutting mild steel and surface finishes that are not always optimal for regular laser cutting. Particularly when cutting different materials (e.g., Hardox or mild steel) and surface qualities (e.g., oxidized or blasted) in mid to high sheet thicknesses, the TruLaser FlexLine flame cutting process results in better quality parts, higher material tolerances, and greater process reliability. FlexLine enables precision laser cutting of filigree contours, even in high sheet thicknesses. The greater flexibility in production created by

FlexLine also helps fabricators increase the variety of jobs they can do. FlexLine technology helps overcome the potential costs and quality concerns related to the laser cutting of thick or mild steel with different surface qualities and compositions.

Video of TRUMPF’s new FlexLine technology is available here.