Make Reducing Waste, Such as Industrial Fluids, a No. 1 Priority

Defective, unused, and excess materials can eat into the bottom line and because it’s so common, many businesses will write it off as “just the cost of doing business.” Now more than ever, it’s imperative that manufacturers find ways to reduce waste as much as possible.

Posted: February 5, 2024

It’s no secret that the economy is tough to navigate. The effects of Covid-19 on business operations have caused waves in economic trends that change how businesses and labor markets function. With inflation slowly rising, employers and business leaders are tightening the belt and reducing costs wherever possible. For most, the easiest solution is layoffs. Last year was a scary year for employees — in the first 9 months of 2023, there were about 605,000 announced layoffs, a 198% increase from last year according to Forbes. Unfortunately, it seems that 2024 will be no different. In a survey conducted by ResumeBuilder.com, 38% of business leaders said that they think layoffs are likely in 2024. However, in an industry like manufacturing, the solution for cutting costs is much more complex than cutting down on labor costs.

Labor Market Trends

The manufacturing industry is already struggling with skilled labor shortage, which is only compounded by the recent economic trends. Although manufacturing is still a highly profitable and constantly evolving field, it’s not as sexy and desirable as it used to be. In an industry hurting for new talent — the U.S. Bureau of Labor Statistics reports that more than 51% of manufacturing jobs in the United States are currently filled by employees aged 45 and up — businesses need to retain their talent to not only continue efficient operation but to train and teach the limited number of next generation employees.

As if a short supply of new talent isn’t enough of a challenge, the industry is also grappling with an extremely tight labor market. In the most recent Employment Statistics Highlights from the U.S. Bureau of Labor Statistics, the manufacturing industry added 12,000 net jobs in 2023, an astounding 97% decrease from the 390,000 net jobs in 2022. Of course, manufacturers have to balance new job openings with market expectations but this enormous drop in the number of new jobs leaves absolutely no wiggle room for employers to employ strategies like layoffs to combat the tight economy. All the factors that contribute to this limited labor market create an extremely competitive environment. Businesses that want to maximize profits and be as efficient as possible will fill their limited labor positions with the best talent they can find. Employers that can’t offer a competitive salary risk having their employees being poached and will have no one to fill their positions.

With no room or opportunity for new talent in a field dominated by senior talent, retaining skilled labor is a No. 1 priority for the manufacturing industry. Even with the continued innovations in automation, any manufacturing business without employees will fail. While other industries are using layoffs to offset the tight economy, the manufacturing industry must find other ways to compensate.

Reducing Waste

Operational efficiency is one of the main areas manufacturers must scrutinize to maximize their cost savings. Waste is one of the costliest byproducts of any manufacturing operation. Defective, unused, and excess materials can eat into the bottom line and because it’s so common, a lot of businesses will write it off as “just the cost of doing business”. Now more than ever, it’s imperative that manufacturers find ways to reduce waste as much as possible.

Common waste streams in manufacturing include the industrial fluids that are routinely disposed of, hauled away, or waste treated on site. Manufacturing processes, especially involving metal fabrication, are inundated with machining coolant and other industrial fluids. Over time, these fluids can get contaminated by tramp oils, metallic or non-metallic fines, and bacteria or fungus. These contaminants can lead to reduction in lubrication efficiency, increase tool wear, cause production issues, and pose threats to the life of the fluids. Finding ways to keep industrial fluids clean while minimizing spend on new purchases and waste disposal should be a top priority for manufacturers.

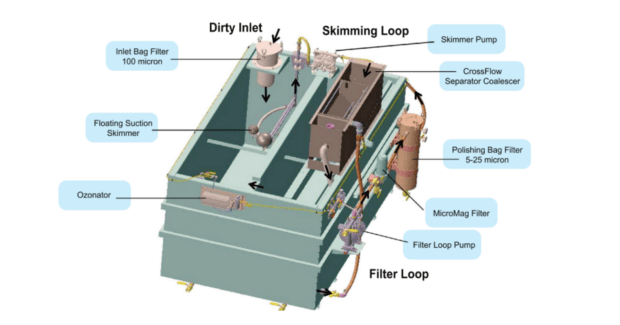

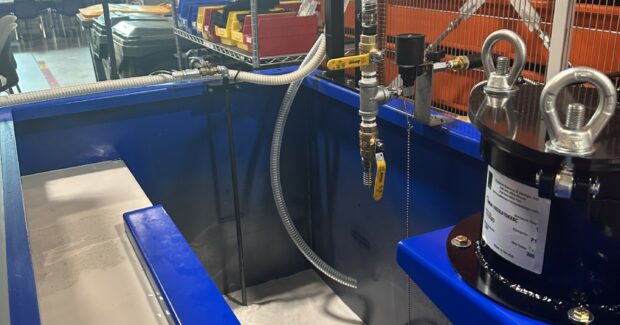

SmartSkim coolant recycling systems are a solution to help remove contaminants from dirty coolant, improve operational efficiency, and drive cost reduction. These recyclers receive contaminated coolant via a sump cleaner, fluid transfer pump, drum vacuum, or some other process. The systems are equipped with a dirty and clean tank, allowing coolant to continuously recirculate and avoid stagnation. A floating suction skimmer feeds an open-channel coalescing oil separator to remove non-emulsified oils from the coolant. Solid contaminants are removed by a rare earth magnetic filter and a pressurized bag filter. An ozonator system is included for biological and odor control. A coolant proportionator and make-up level control is also provided to recharge the system with new coolant.

This straightforward process leads to direct purchase cost savings. Coolant recycling systems can reduce new coolant purchases by 35%-to-65% and dirty coolant disposal by 75%-to-95%. Additional benefits include reducing environmental risks and off-site disposal liability, more consistent coolant concentration control, and water usage reduction. When Maxion Wheels, a leading manufacturer of steel and aluminum wheels in the automotive industry, installed a SmartSkim coolant recycling system from Sentry Equipment, the company reported $127,787 in savings over the course of six months. On average, customers experience full payback in recycling systems between six months and 12 months.

Coolant recycling systems work twofold when it comes to reducing costs. Along with directly reducing purchase costs, they increase operational efficiency. Cleaner coolants improve the lifespan of tooling, pumps, and other valuable production equipment. The efficiency of employees also increases — coolant recycling systems decrease the man-hours spent managing coolants while simultaneously enhancing worker safety by decreasing the exposure to contaminants. M&M International purchased a SmartSkim coolant recycling system and noticed their shop smelling better with much less mist and smoke.

More Opportunities to Increase Efficiency

Finding ways to reduce waste is a great way to increase efficiency and maximize cost savings in manufacturing, but it’s far from the only solution. Although it may sound obvious, digitizing as many processes as possible can be a great way to maximize production. Cutting out paper and moving to digital management systems can improve information-based decision making, streamline training processes and increase productivity. Another solution for reducing operations cost is implementing better preventative maintenance protocols. One of the biggest costs manufacturers can fall to is emergency downtime. When manufacturers have machine downtime, the amount of money lost can be devastating. Not only are emergency repairs very expensive, but production can be completely halted, which reduces output and negatively affects profit. Creating a schedule-based preventative maintenance strategy can extend the life of equipment and can help staff proactively identify problems with equipment before it fails.

With the economy as tight as ever, finding ways to maximize profitability has never been more important. And in manufacturing, layoffs are simply not an option because the labor market is extremely limited. Manufacturers that make smart decisions to improve their operations can not only drive significant cost savings but can also keep employees productive and take on 2024 with confidence.