Machine Tending Systems Seamlessly Integrate with a Range of Metalworking Processes

Machine tending products, led by cobots, tackle repeatable tasks without compromising quality production, as well as operator safety.

Posted: February 15, 2024

The launch of new, adaptable and flexible machine tending products is essential for handling the diverse needs of different production lines in a wide range of manufacturing industries.

Highly Precise Bolt-picking Robot Cell for Automotive Assembly

KUKA Robotics’ (Shelby Township, MI) KR AGILUS is a compact, 6-axis robot designed for particularly high working speeds that reduce cycle times and increase production quality. The KR AGILUS adapts to any installation position and a wide range of variants, including clean room, hygienic machine and waterproof, allowing it to perform in almost any environment. Continuous productivity is ensured with minimal maintenance requirements and gear units that never need lubricant change.

The KR 6 effortlessly performs operations such as bin and bolt picking to improve production, reduce error and streamline processes. The robot is guided by a KEYENCE 3D Vision System that identifies which parts to pick and calculates the optimal robot motion paths to avoid collisions as it selects, picks and deposits the bolts. By detecting bolt positions and sending those coordinates to the robot, the KEYENCE system enables faster, more flexible picking. It also outperforms traditional bowl feeding systems, providing increased uptime and availability required in high throughput automotive applications.

Automate Machine Tending Processes to Boost Productivity

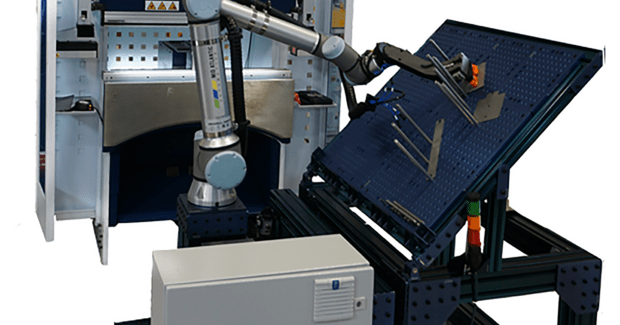

AutoTend™ by Mid Atlantic Machinery Automation (Harrisburg, PA) is the automated machine tending system to tackle your repeatable tasks with consistency and efficiency — all the while improving your bottom line. Our forming cell consists of a collaborative robot integrated with your existing press brake or a new press brake. With our streamlined, easy to use programming system, operators of any skill set can tackle parts programming. This system allows any press brake to become a fully automated cell or a manual use brake when a robot is deployed to another machine in your shop.

CNC Machine Feeding Kit Increases Productivity up to 300%

PBC (Pacific Bearing Co.) Linear (Roscoe, IL), a global leader in linear motion solutions, offers the Cobot Feeder, a CNC machine feeding application kit that delivers and stages parts to be placed into a machining process. The company received Universal Robots (UR)+ partner certification last year.

The Cobot Feeder kit includes a base storage and retrieval unit with a UR cobot pedestal, an enclosed steel rack dunnage tower with a 17-tray capacity that safely stores up to 50 pounds of material, an HMI touchscreen display for easy lift control, Ethernet IP, Modbus, and standard UR cobot communications. By reliably loading and unloading dunnage trays, this versatile CNC machine-tending tool provides a standardized platform for storing, staging, and delivering parts into a position that the UR cobot can reach for loading and unloading.

“By increasing the amount of raw materials to a work cell, the Cobot Feeder’s 17-tray, high-density, part-storage solution enables a machining, welding, stamping, forming, or deburring center to operate for longer periods of time without human interaction, significantly increasing productivity by up to 300% or more,” said Beau Wileman, applied cobotics and 3D platform product manager for PBC Linear. “In many cases, this means a cobot work cell operating eight hours a day during normal business operations can continue to work through shifts two and three, providing lights-out operation around the clock.”

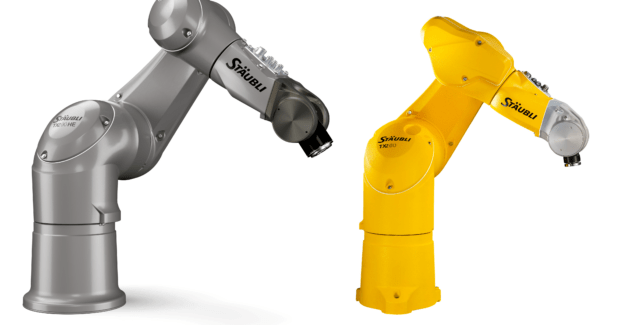

Machine Tending Robots Improve Efficiency and Reduce Costs

Robotic machine tending offers solutions to age-old pressures to improve efficiency and productivity without compromising quality or safety. As requirements grow stricter, the drive to modernize production is taking on greater urgency. Stäubli Corp.’s (Novi, MI) experience in machine tool loading/unloading means the company can work with manufacturers and system integrators to design industrial robots for applications on all machine types: single, twin and multi-spindle lathes, rotary/linear transfer machines, machining/tapping centers, and grinding, honing, boring, cutting as well as superfinishing machines.

Stäubli’s products are known for their high precision and repeatability, which is crucial for accurately loading and unloading parts in a machine, leading to improved product quality. Stäubli’s products are also designed to be fast and efficient, allowing for quick cycle times in machine tending applications. This helps to increase productivity and reduce overall production time. Highly flexible, the products can be easily programmed to manage a wide range of parts and machines, making them suitable for a variety of machine tending applications.

Leading Provider of Cobots Launches New 30 kg Cobot

Universal Robots (Odense, Denmark) is expanding its leading product portfolio with a new 30 kg payload cobot. The UR30 is the second in Universal Robot’s new series of innovative, next generation cobots and is built on the same architecture as the award-winning UR20. Despite its compact size, UR30 offers extraordinary lift, and its superior motion control ensures the perfect placement of large payloads allowing it to work at higher speeds and lift heavier loads.

The UR30 is ideal for several applications including machine tending, material handling and high torque screw driving. For machine tending, the high payload brings new possibilities as it allows the cobot to use multiple grippers at the same time, which means it can remove finished parts and load more material in a single pass, shortening changeover times.

“As industries evolve, the UR30 not only meets but anticipates shifting demands, enabling businesses to adapt and respond to changing needs effectively,” said UR President Kim Povlsen. “As we continue to innovate, the UR30 is another step in UR’s journey in pushing the boundaries of what is possible in the world of automation.”