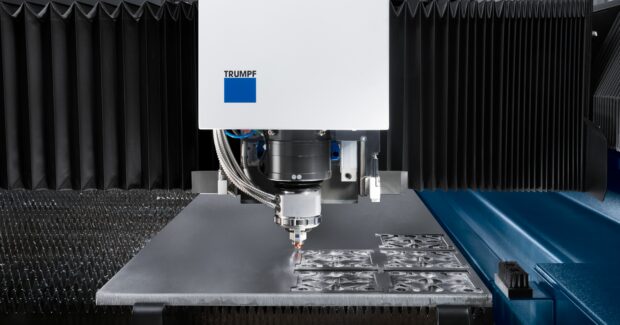

Ultra-High-Power Lasers Tackle Ultra Heavy Plate

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

Posted: January 24, 2024

For a long time during the 1990s and early 2000s, the available output power of industrial sheet-cutting lasers crept upward in fairly small increments. Due to the nature of CO2-based laser sources, there were a lot of difficulties in squeezing extra useful power out of the beam generator. Generally speaking, these devices were extremely inefficient electrically — somewhere on the order of around 10% wall-plug efficiency was fairly typical — and the running joke with operators of CO2 lasers above 6 kilowatts was that you could watch the dial on your electrical meter warp spacetime when the machine was cutting because of how much juice it would pull. While that may have been overexaggerated, it was certainly true that those lasers consumed massive amounts of power to operate. Electrical inefficiency also drives a huge amount of wasted heat production in CO2 lasers, which drives the need for massive amounts of liquid cooling to dissipate the heat, which further reduces the energy efficiency of the equipment.

Aside from these design limitations, machine developers also learned there was a practical limit to how much power you could actually use with CO2 laser technology. Beyond around 7 kilowatts or 8 kilowatts, increasing power from the laser source used to result in decreasing benefits. At a certain point, the low absorption coefficient of the laser energy meant that more heat thrown at the metal did not result in better cutting. The opposite was often true: Too much power from a 10-micron wavelength CO2 laser source would decrease cutting performance because of the heat dissipation into the material, and result in very poor edge quality, or even welding the metal rather than cutting.

This calculus has changed substantially now that the dominant laser source technology is 1-micron wavelength solid-state lasers instead. The different frequency of light these lasers emit is absorbed much more readily by metals, or in other words: 6 kilowatts of 1 micron laser energy will melt metal much faster than 6 kilowatts of 10-micron laser energy. The increase in cutting efficiency is also complemented by the higher electrical efficiency of solid-state lasers compared to gas lasers. Typical wall-plug efficiencies for solid-state lasers are more than 30%, or at least three times better than a comparable CO2 based laser. Greater operating efficiency of the laser also reduces waste heat loading, and in a virtuous cycle, this reduces the need for cooling, which further reduces the electrical consumption.

The upshot of all of this is that the upper limit of useful energy output is much higher for solid-state lasers sources than for gas lasers. Instead of hitting a “performance plateau” around 7,000 watts, these solid-state lasers sources can continue to operate efficiently and increase cutting performance all the way to 20,000 watts of output power and beyond. Which, of course, means that now there is a good reason for machine builders to develop and offer lasers at these ultra-high output ranges, and good reasons for machine users to consider buying them.

Who Benefits from Ultra-Power Lasers?

This should not be read to mean that every laser operator needs the highest possible laser power. Not all metal processing applications benefit from extremely high laser powers. The most obvious example being fabricators that process primarily thinner materials: There is still very much a diminishing benefit for increasing laser power when we look at cutting sheets under ¼” in material thickness. The “performance plateau” for solid-state lasers cutting relatively thin sheets is going to lie somewhere between 10,000 watts and 12,000 watts of output power. Increasing power beyond this level might get you a bit more cutting speed, but not much, and probably not enough to justify the higher investment and operating costs.

On the other hand, the high efficiency and high energy-output potential of solid-state lasers opens up some great opportunities for fabricators who process thicker plates. One of the classic motivators for seeking higher laser power is the ability to fusion-cut greater thicknesses of mild steel. Fusion cutting steel using inert nitrogen as the assist gas has the great benefit that the cut edge is chemically pure, not coated with a layer of iron oxides, as in the case of cutting steel with oxygen or compressed air for the assist gas. For most steel products, that oxide layer must be removed somehow before the cut parts can go on to welding and/or painting, so cutting oxide-free parts can possibly eliminate a secondary handling step. The thickness limit for cutting steel with nitrogen is driven entirely by available laser power, so being able to throw more watts at the sheet means thicker and thicker metals can be processed. Lasers with 20 kilowatts or more of output power can push the limit for fusion cutting steel well beyond ½” thick, which will be very beneficial for certain types of fabrication operations.

Aside from pushing thicker plates through the machine with nitrogen assist, higher laser powers also increase the overall thickness limit the machines can process. Whereas in the past the upper limit for most laser machines was around 1” plate thickness, lasers in the ultra-high-power range can push well beyond this threshold. Suddenly the laser can be used as a tool to process steel, stainless and aluminum thicknesses that would have been forced onto a plasma table or waterjet previously. With more than 20 kilowatts of power available, the cutting thickness limit can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser into a whole new range of parts and products. This new breed of very high-output solid-state lasers not only makes these new applications possible, but it also makes them practical and profitable as well.