Spin or Stir? Automated Friction Welding Grows in Popularity

Friction welding processes — both FSW and RFW — offer a unique blend of efficiency and productivity in a growing range of contemporary applications.

Posted: January 4, 2024

The process of joining metals using friction-generated heat originated in the early 1900s in the form of rotary friction welding (RFW). A variation on that concept, friction-stir welding (FSW), was patented in the 1990s. Both processes are highly effective in selected applications. In fact, the use of fully automated FSW and RFW systems is gaining popularity in industry sectors ranging from automotive electric vehicle (EV) production to truck axles, hydraulic cylinders and oil and gas exploration.

In friction-stir welding, a rotating tool with a central pin generates heat as it spins and moves along a joint between two components, plasticizing the materials being joined. The unique process characteristics of FSW are prompting manufacturers to apply it in joining materials that previously have been difficult or even impossible to weld reliably and economically with traditional welding techniques. Typical problem jobs include joining thin-gauge and high-grade aluminum components, copper alloys or dissimilar materials.

Robotic-based FSW systems, such as those from KUKA Robotics, are engineered to support high process efficiency in terms of low investment costs, maximum versatility and multiple configuration options. The systems offer consistent reliability and repeatability that are essential in manufacturing environments.

These systems represent scalable solutions and provide high efficiency (up to 95%) via the use of multiple workstations that permit simultaneous welding by several robots for complex larger components. KUKA path calibration technology generates path accuracy up to 0.5 mm.

KUKA’s FSW application modules offer system integrators and end users maximum flexibility, permitting use of heavy-duty robots with process-specific software and hardware additions and expansions. The company’s Cell4_FSW module is engineered for use with the KR500 R2830 FORTEC MT robot with a KR C4 controller and an FSW 3 spindle with spindle cooling.

The Cell4_FSW package is Industry 4.0 ready, with interfaces based on OPC UA for easy data exchange. KUKA specifically developed the Process Control and Documentation (PCD) system for continuous-path FSW processes. PCD provides 100% real-time process monitoring as well as tracking of numerical and graphical parameters. It also delivers component and product data management and export, process diagnostics, electronic documentation and archiving of all process data.

Offering connectivity to cloud systems, the PCD ensures high productivity, traceable quality and data transparency. Cell4_FSW friction welding cells are seeing increased use for battery and electronics housings in the growing EV market.

Rotary Friction Welding Processes

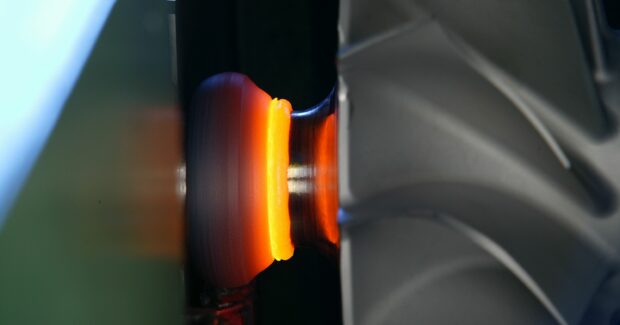

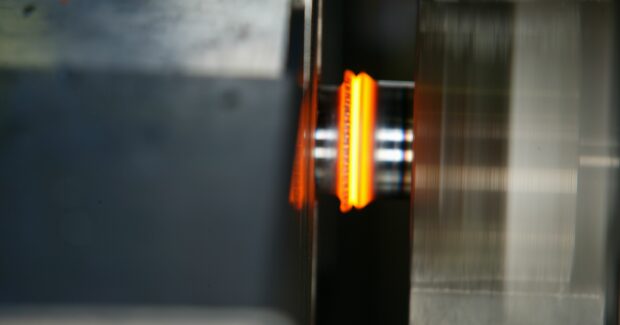

In the rotary friction welding process, two parts of circular cross section are brought together, one rotating and one held stationery, until the parent materials soften and plasticize. The application of forge force during or after part rotation completes the weld.

Longtime welding equipment manufacturer Thompson, now part of KUKA, has more than 60 years experience in developing and manufacturing a wide selection of standard and special friction welding machinery. Thompson’s products are designed for automatically welding an extensive variety of parts, ranging from small diameter components such as engine valves and electrical connectors, to medium diameter parts including drive shafts and hydraulic cylinders, and also large diameter assemblies such as API drill pipes and trailer axle tubes.

Thompson’s single- and double-ended machines are based on platforms from 15-to-400 tons in capacity, producing forging pressures from four-to-400 tons. Standard and custom machines can feature additional capabilities including external and internal flash and upset removal systems.

Thompson dedicated welder control software is programmed to provide the basic capabilities needed to set up and operate a friction welding machine. The PC-compatible platform enables intuitive programming and seamless connectivity. Straightforward automatic or manual programmable solutions offer control throughout the weld cycle of almost any special features that a particular application may require.

Despite somewhat limited familiarity amidst a significant portion of the present manufacturing community, friction welding processes — both FSW and RFW — offer a unique blend of efficiency and productivity in a growing range of contemporary applications. New product technologies such as EV transportation and an increase of product designs requiring bonding of difficult-to-weld and dissimilar materials are stirring (and spinning) new interest in the uniquely capable process of automated friction welding.