Machining: Optimize the Solutions

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

Posted: January 24, 2024

Fabricating & Metalworking asked leading machine tool manufacturers to answer the question: Machining: Optimize the Solutions-What’s next for the metal removal sector?

Machine tool technologies that are stacked with innovative features are essential to overcoming design and production challenges in order to deliver superior products that various industry sectors expect — now and for years to come. Combining these innovative machines with automation, be it robots, pallets and other components that support unattended manufacturing, brings flexibility and increased productivity to your shop.

And don’t forget energy-efficient processes that monitor your machines so operators can save power and reduce energy consumption and costs. What’s more, sludge-less tank technologies enable users to run machines longer with less impact on the environment. These efforts not only help the environment, but they also extend the life of your machines.

Also vital to machine tool longevity and successful processes are modular tooling systems. These systems enable manufacturers to optimize solutions because they provide versatility to support a range of machining needs. Precision engineering and the flexibility of these systems make certain manufacturers obtain accuracy in their operations.

With the continued advances in industry sectors such as automotive and electric vehicle developments, industries depend on their partners to address their needs through advances such as multiple machining processes, with added functions such as additive manufacturing, high-precision gear cutting, or friction stir welding processes.

Below, machine tool manufacturers discuss the latest advances in machining that enable your shop to run more efficiently while producing more parts with less staff.

Integration of AI Makes Machines Easier to Use

What’s next for the metal removal sector is a continued growth in the use of high-speed milling machines and automation, in particular, those types of machine tools within palletized systems, such as those by GF Machining Solutions (Lincolnshire, IL). As the lack of skilled labor continues, more manufacturers will look to these systems to not only optimize the output of their existing workforces but to also increase sustainability.

As everyone in the industry is aware, there’s been a huge push towards automation. However, automation tends to create a Catch-22-type scenario for manufacturers: While the automation fills one skills gap, it essentially creates another. The other gap is the need for individuals with the skills to make the automation work.

No one will debate the fact that automation makes unskilled labor more productive, but it really only does so for processing dedicated parts in high-volume production environments. It is in high-mix/low-volume production where the automation requires that other automation-dedicated skill set.

With that said, the industry will experience an increase in the integration of artificial intelligence (AI) into automated systems. This will make them easier to integrate and use, especially in high-mix/low-volume applications, which in turn will translate into more manufacturers incorporating automation, in particular palletized cells with mobile robots serving multiple machine tools.

These automated cells allow manufacturers to not only run high production, but also high-mix/low-volume jobs as well. Plus, the incorporation of high-speed milling machines further increases the overall output capabilities of these cells along with a manufacturer’s sustainability.

While high-speed machining has been around for quite some time, only recently have more manufacturers embraced the technology. Those that have are processing parts with less resources in the form of time, cutting tools and electricity. Plus, today’s machine tools are now equipped with energy-saving features. An example is one that allows manufacturers to pre-program machine warmups to happen during unmanned hours. This eliminates the risk of running the machine when it’s not at its peak operating temperature and wasting resources on producing a scrapped part as a result. — Christian Meekma, milling product manager, GF Machining Solutions

Modular Tooling Systems Facilitate Flexibility and Multiple Tooling Combinations

In the world of metal removal, the demand for efficiency, flexibility and precision continues to drive innovation. As we explore the future of the metal removal sector at Sandvik Coromant (Mebane, NC), the spotlight falls on the potential of modular tooling systems.

Modular tooling systems are the keystones in adaptability to an ever-changing production environment and empower manufacturers to optimize their solutions by providing a versatile platform that accommodates various machining needs. The key advantage lies in the ability to swiftly adapt to changing production requirements without compromising precision. This flexibility is vital in an industry where adaptability is synonymous with competitiveness.

One of the notable advantages of modular tooling systems is the ease of tool changeovers. Whether transitioning between different workpieces, materials or part fixturing, the modular approach streamlines the process, minimizing downtime and maximizing productivity. Over the years, I have witnessed firsthand how this approach fosters operational agility, allowing manufacturers to stay ahead of the curve.

The modular tooling landscape continues to witness advancements in the latest cutting tools and assortment, pushing the boundaries of performance. Enhanced flexibility, paired with precision engineering, ensures that manufacturers can achieve the highest levels of accuracy in their machining operations.

In conclusion, the future of the metal removal sector is intricately linked with the adoption and enhancements of modular tooling systems. Moving forward, we must embrace the power of flexibility, efficiency and precision that modular tooling brings to the forefront. It’s not just a trend; it’s a paradigm shift that will redefine the way we approach metal removal, setting new standards for innovation in the machining industry. — Curt Holbrook, engineering projects manager – automotive, Sandvik Coromant.

Helping Shops, Small and Large, Optimize Production and Reduce Costs

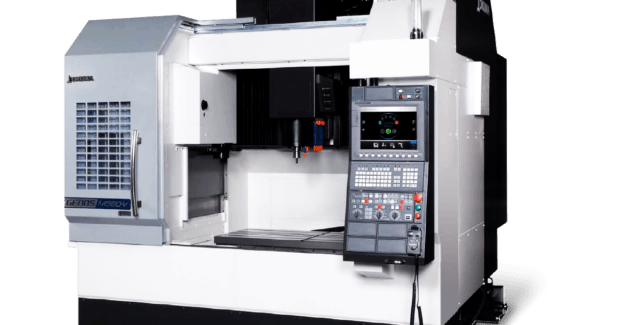

JTEKT’s horizontal machining centers, the FH5000S HMCs with 60-tool ATC capacity, are designed for speed and production reliability.

A recently introduced horizontal machining center (HMC) range shows how JTEKT (Arlington Heights, IL) is meeting the growing need to produce a wide variety of components with high metal removal rates, short cycle times and superior surface finishes.

“We determined that the sweet spot of the machining center market — typically a 600 mm table —needed greater machining capacity, flexibility and productivity,” said Graham Roeder, JTEKT’s national product manager. “Designing pallet automation for this machine range provides shops with greater possibilities for unattended production at a more competitive price point.”

Answering the global need to do more in a more compact machine, JTEKT engineered the FH5000 series with a 500 mm table that can accommodate parts typically put on a 630 mm table. The table can handle 1,000 kg loads.

The competitive advantage of FH5000 machines is that they offer 25% more machining capacity than other machines in their size range. “We call that higher part density within the working envelope of the machine,” Roeder said.

To offer the benefits of unattended production to shops of any size, JTEKT designed and produced pallet changers for single machines, as well as pallet pools for flexible machining systems, which permit longer running time, Roeder added.

To support unattended machining JTEKT also includes adaptive control in its standard machine package, which allows users to manage tool life through acceptable spindle load ranges. The machine, control, and pallet automation are all JTEKT designed and built to operate seamlessly as a system.

“We help users with the strategy that will allow them to handle more machining in one machine, with tool complements from 50 to over 300 tools,” Roeder said. “So, with pallet automation, adaptive control, large tool complements onboard, 25% higher part density in a 160 sq. ft. floorspace, we are helping small and larger shops in general machining, aerospace and other industries to optimize production and reduce production cost.

Multi-tasking: Maintain Competitiveness in the Coming Years and Beyond

Shops — both large and small — must continue to invest in innovative technology to overcome industry challenges and compete effectively in expected growth industry sectors. Machine tool technologies that will factor significantly into the equation include those that provide multi-tasking capabilities and those that perform full 5-axis machining. Above all, these machines will be paired with some form of automation, whether simple or sophisticated.

Multi-tasking machines such as Mazak’s (Florence, KY) INTEGREX, VARIAXIS NEO and MULTIPLEX Series will continue to allow manufacturers to produce more parts with less capital equipment. They also significantly reduce work in progress (WIP) and maximize the output of existing labor forces while boosting overall part quality.

Taking the multi-tasking concept a step further, Mazak HYBRID Multi-Tasking machines combine additive and secondary processes such as friction stir welding, hot wire laser deposition and high-precision gear cutting into single machine platforms for even more efficient production.

Like multi-tasking machines, those with full simultaneous 5-axis machining capabilities can provide complete part machining with fewer setup changes. Equipped with powerful high-speed lookahead controls, these machines give manufacturers the ability to successfully machine the most complex part designs.

Growth in machine tool automation continues to surge and can entail systems from simple bar feeders, parts catchers and gantry loaders to cobots, articulated standalone robots or multi-level palletized cells such as Mazak’s PALLETECH Automation System. Automation, together with the latest machine tool technology, gives manufacturers the ability to overcome shortages of skilled labor, increase their overall productivity and drive profitability.

Overcoming challenges and maintaining competitiveness in the coming years and beyond requires examination of and updates to metal removal technology. Doing so will allow shops to optimize their machining operations and ensure success. — Dan Janka, president of Mazak

Energy Saving Technologies Extend the Life of Your Machine Tools

What I see as the next big thing in metalworking is the turn to more energy-saving technologies so shops can save money and time and lengthen the longevity of their machine tool. At Okuma (Charlotte, NC), we have developed many different energy-saving technologies over the years such as the Power Regeneration System, Thermo-Friendly Concept, Eco Suite Plus, and a sludge-less coolant tank.

The earliest of these is the Power Regeneration System, circa 1997, which utilized the energy generated during deceleration, which in the past was discarded. Then came the Thermo-Friendly Concept in 2001, which reduces warm up cycle time, which then reduces electricity use. This feature allows machining centers to minimize the heat generated, and deal with the heat that can’t be eliminated, to maintain high accuracy thanks to the control and the symmetrical machine build structure.

In 2022, we launched Eco Suite Plus, a function that allows users to monitor various on-machine devices and peripheral equipment to view, record and analyze the machine’s power consumption. Operators can then determine what items to turn off using Eco Idle, either automatically or manually, to save power and reduce energy consumption. With the push of a button, Eco Suite Plus allows users to turn off oil coolers, chip conveyors, mist collectors and more.

Also, in 2022 we debuted the sludge-less tank concept, which constantly moves and filters used coolant, preventing any sludge from accumulating in the tank. This allows users to run the machine longer with less impact to the environment while also reducing coolant replacement time and cost.

Today, we offer the Green-Smart Machine, which is a combination of all the current energy saving technologies wrapped up in one package. — Ron Raniszewski, applications engineering supervisor-machining centers, Okuma America