How Best to Benefit from Automation, Flexibility and the Resulting Efficiencies

New advancements in the machine tool sector overcome challenges and optimize a shop’s operations, just in time to support a forecasted uptick in the manufacturing economy.

Posted: January 24, 2024

There are all sorts of moving parts in the metalworking economy, which means there is no better time to seize the opportunities unfolding, particularly in regard to innovative machinery and automation solutions.

Manufacturing organizations and PMI survey data point to a manufacturing industry expansion in the first quarter of this year, even though the Institute for Supply Management’s PMI for December 2023 was below 50% at 47.4%, indicating a contracting market. But it is a contraction that has slowed down.

In 15 of the 18 manufacturing industries surveyed, 58% of respondents expect revenues to be greater in 2024 than 2023, according to ISM’s “2023 Semiannual Economic Forecast,” released in December. Capital expenditures are expected to increase by 11.9%. “They [survey respondents] are optimistic about overall business prospects for the first half of 2024 and more excited about faster growth in the second half,” said Tim Fiore, chair of the ISM Manufacturing Business Survey.

Below is a sampling from December’s ISM Report on Business regarding metal industry related respondents:

- “We are forecasting a somewhat strong year for 2024. We’re currently mildly optimistic for how next year will play out.” (Fabricated Metal Products)

- “Demand is up across the board. We are starting to see back orders grow again.” (Transportation Equipment)

- “Business is slowing. Finished goods inventories are growing.” (Machinery)

- “We are seeing stronger demand from our American automotive OEM customers now that the United Auto Workers strike has been resolved. Looking at a very strong first quarter of 2024.” (Primary Metals)

Ride the Wave

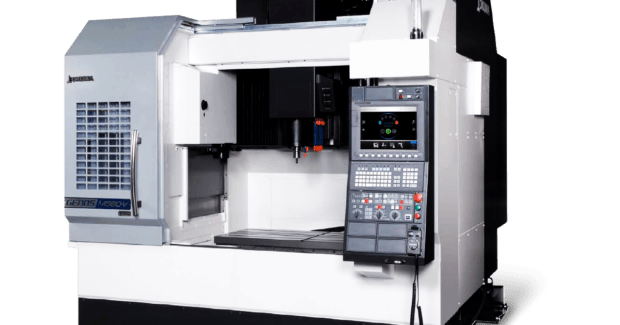

Leading machine tool manufacturers are building machines to assist your shop in taking advantage of the opportunities this year is projected to bring. In this issue’s cover story, leading suppliers discuss what’s next for the metal removal sector. These innovators highlight the latest advances in machining that enable shops — small, mid-size and large — to run more efficiently and produce more parts in a skilled labor-constrained market.

Combining these innovative multiple machining process machines with automation, be it robots, pallets or other components that support unattended manufacturing, brings flexibility and increased productivity to your shop. Operators are performing more functions on one machine, which feature compact footprints, and abundant tool capacity. Modular tooling systems, which are linked to the future of the metal removal sector, allow operators to quickly adapt to changing production requirements.

And when it comes to sustainability initiatives, there are complete suites of energy saving technologies available to monitor and reduce the energy consumption of your machines.

Take advantage of the technology trends by investing in the right tools to compete in and shape the future of the dynamic metalworking economy.