CMMs: Indispensable Tools Ensure Precise and Comprehensive Measurement

CMMs are invaluable in industries where quality and compliance with specifications are paramount.

Posted: January 24, 2024

Technological advances in Coordinate Measurement Machines address the diverse needs required in the latest manufacturing and inspection processes, such as with electric vehicles, contributing to improved accuracy, throughput, and overall quality assurance.

Gauge Confirms Accuracy of Measuring Machines After Calibration

LK Metrology, Inc.’s (Hudson Heights, MI) range of UKAS-certified length and form gauges, complete with holding fixture, is offered by coordinate measuring machine (CMM) manufacturer LK Metrology, allowing the inspection accuracy of any 3D measuring platform to be verified. The user can have greater confidence in the results of an inspection, whether for metrology or reverse engineering, long after the typical annual calibration of the measuring machine has been carried out.

Each CMM Checking Gauge (CCG) enables independent monitoring and verification of accuracy through regular intermediate checks on a CMM or portable measuring arm. An OEM can be certain that prototypes and production parts are within tolerance, while subcontractors are able to assure their customers that machining and inspection carried out on their behalf are accurate. It demonstrates a commitment to a consistently high standard of dimensional quality control. Gauge measurement tolerance is ± 0.01 μm.

The CCG provides an efficient go/no-go check with measurement results for ongoing CMM monitoring. Three combinations of length bars, ring gauge, test sphere and fixture of different sizes are available to suit various measuring machine models. Regular use provides early warning of changes in the inspection system and an opportunity to take pre-emptive action. Once identified, accuracy issues due perhaps to environmental changes or an unnoticed probe crash can be addressed by scheduling an interim machine service or calibration before downstream manufacturing processes are impacted.

The gauge is supplied in a carrying case with a program on a USB drive that runs in LK’s CAMIO measuring and reporting software. The program includes DMIS measurement and alignment routines for bridge and horizontal arm CMMs, allowing the CCG cycle to run seamlessly on LK machines. However, it is easy for operators of other 3D measuring platforms using different software to program a probing cycle around the gauge to check for machine accuracy.

5-axis Technology Offers a Future-Proof Inspection Solution

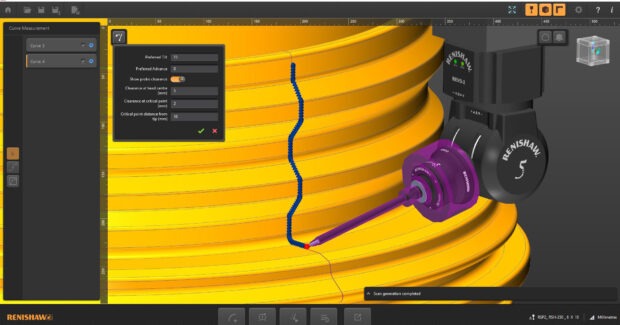

Renishaw Inc.’s (West Dundee, IL) REVO® 5-axis multi-sensor system, with its extensive range of probes, provides automatic switching between tactile scanning, touch-trigger, ultrasonic, vision and surface finish measurement. The REVO system’s innovative design maximizes CMM inspection capabilities with patented 5-axis measurement technology.

By integrating multiple sensors on the same CMM reference frame, the system enables manufacturers to increase productivity significantly and can eliminate the need for other dedicated inspection equipment. This single-machine solution overcomes the delays and risks of damage associated with the transferring of parts across multiple inspection locations. Reducing part handling and part movement minimizes scrap and optimizes shop floor layout, leading to lower energy consumption.

The REVO system’s 5-axis technology offers a future-proof inspection solution to manufacturers across aerospace, automotive, medical and other industries. Synchronizing the motion of the three CMM axes and the measuring head’s two axes minimizes the CMM’s dynamic errors at ultra-high measuring speeds. It also provides access to part features out of reach for conventional 3-axis systems. Furthermore, enhanced inspection capability enables manufacturers to improve their designs and allows for more complex part manufacture.

Quality control is evolving from simple pass or fail checks into a far more valuable investment of time, where the data is used to actively fine-tune process control limits. Agile and flexible 5-axis inspection technologies offer a powerful tool that can be repurposed repeatedly for each new design or product. The REVO system can play an integral part in creating a more streamlined, efficient and cost-effective manufacturing process.

An integral element of the 5-axis measurement solution is the software, and Renishaw’s MODUS 1.12 software offers multiple enhancements in flexibility and usability for REVO sensors. New features within its specialist tools include, for programming (MODUS Planning Suite), and for reporting (MODUS CHART). Additionally, MODUS software enhances process monitoring capability by linking directly to the Renishaw Central manufacturing connectivity and data platform.

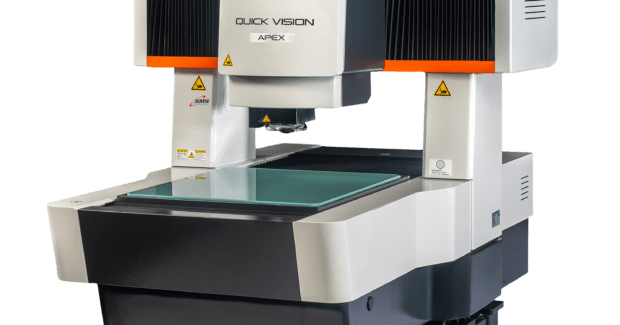

Leading Vision Systems Manufacturer Adds new Enhancements

Mitutoyo America Corp., (Aurora, IL) a leading manufacturer of precision metrology instruments and solutions, has added new enhancements to its Vision Pro vision measurement system line. The most recent market research shows the vision machine measuring market is set to explode with an expected value of $41 billion by 2030.

Mitutoyo’s introduction of the QV Vision Pro Series has set the stage for the future of vision measurement with several new features. The StrobeSnap vision measuring function speeds up quality run time compared to other competitor’s machines by approximately 35%-to-45% regardless of measurement position or continuity while achieving higher throughput and high-precision measurements. Additionally, autofocus on the QV Pro Series is about 39% faster than previous models, which were already the fastest in their class, without loss of accuracy for measurement.

Vision measurement is taking on a larger role in the construction of electric vehicles, where the motors are typically composed of several layers of rotors that are stamped and stacked on top of each other and laminated together. Vision measurement offers an accurate, effective, and cost-effective solution for parts quality inspection.