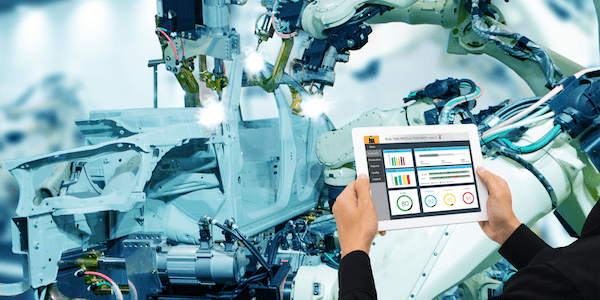

Accelerate Digital Initiatives and Drive Efficiencies

AI and cloud technologies make certain you remain competitive and can quickly respond to the evolving manufacturing landscape.

Posted: January 3, 2024

There are more ways than ever to connect processes taking place on the shop floor. Easy-to-use solutions assist you in achieving overall equipment efficiency.

New Software Platform Unlocks the Full Potential of Factory Data

ABB Robotics’ (Auburn Hills, MI) new modular OptiFact™ software platform streamlines data collection, visualization, and analysis in automated production facilities. The platform enables users to collect, manage, and analyze data from hundreds of factory devices, including ABB robots, to determine key performance indicators including cycle time and overall equipment efficiency. By speeding up diagnostics and decision-making, OptiFact increases the production line uptime with less engineering effort, ensuring production can keep pace with customer demand.

Digitization, the acceleration of sustainable manufacturing and the pandemic have all contributed to the increased demand for automation solutions. Growing reliance on automation has resulted in increasingly complex production environments, driving demand for tools to enable plant managers to collect and capitalize on data gathered as a side product of automation.

With OptiFact, factory operators can determine the root cause of production errors and use ABB’s RobotStudio® Cloud to make adjustments to the program and develop an improved robotic solution. RobotStudio’s desktop, cloud, and AR viewer solutions help users easily plan and imagine new deployments of ABB industrial robots or adapt existing ones to new production tasks. Its innovative features such as Automatic Path Planning allow robots to determine the most efficient paths and avoid collisions with existing obstacles. Offering a true “what you see is what you get” user experience with 99% accuracy between the robot’s digital twin and its real-world deployment, RobotStudio speeds design and commissioning time by up to 50%. Application-specific AI-driven software technology such as ABB’s Item Picker offer value-added features that facilitate the realization of robotics deployments with enhanced performance, safety and quality.

New Suite Connects Workers to Real-time Data for Actionable Insights

Hexagon’s Manufacturing Intelligence (MI) division (North Kingstown, RI) offers the Nexus Connected Worker, a suite of manufacturing software solutions that connects workers to real-time data for actionable insights and reporting on operations, maintenance, quality and audits. Powered by Hexagon’s Nexus, a digital-reality platform for manufacturers that simplifies collaboration across departments, the suite offers enterprise-system integration and provides a central location for digital representations of assets, processes, and production facilities to support decision making.

The ability to correct course using guidance from shop floor data is an advantage for manufacturers. Because rigid departmental divisions have long been the industry operating norm, breaking down these siloes remains a challenge despite the need for better data collection and information sharing being clearer than ever before. Nexus Connected Worker provides the operational agility and the IoT connectivity needed for a responsive workforce to react to immediate needs and glean insights from data that has been collected over time. The mobile-first applications can be easily accessed from the shop floor and the workflows can be tailored to meet specific needs across industries.

The software-as-a-service (SaaS) applications, which are now adapted and available through Hexagon’s Nexus digital-reality platform, will be further developed to meet the future needs of the connected worker. New use cases will benefit from connectivity with other relevant applications and data sources connected to Nexus, including Hexagon’s apps for metrology reporting and asset management.

Press Shop of the Future

Schuler North America’s (Canton, MI) Press Shop of the Future supports metalworkers in optimizing costs, output, and their carbon footprint with the help of technologies that maximize overall equipment effectiveness and implement digitalization. The company showcased the Press Shop of the Future at FABTECH 2023.

“Schuler is the market and technology leader for customer-driven innovation and has been serving the metal forming industry for 185 years,” said Kevin McAllister, president, Schuler North America. “The

Press Shop of the Future goes beyond digital tools; it comprises Schuler technology, service support, and digital solutions to create a fully networked press shop.”

At FABTECH, Schuler demonstrated Visual Die Protection (VDP), Schuler Connect, and Machine Applications (edge-to-cloud solutions) from Schuler’s Digital Suite. VDP is a camera-based system designed to stop presses before damage occurs. Schuler demonstrated immediate ROI from VDP’s capability to detect foreign objects, inspect processes, and monitor die functions. A demo of Schuler Connect showcased remote service and troubleshooting support via smart glasses, smart phone or tablet. And Machine Applications demonstrated digital press shop planning practices that provide predictive maintenance to avoid efficiency losses and damage risks.

https://digitalsuite.schulergroup.com