Syncing Simulation and Reality

Accelerating time to market and ensuring quality with virtual assembly.

Posted: December 19, 2023

How can design be optimized to reflect the manufacturing process? I had a “lightbulb moment” when an executive from a leading automotive OEM asked this question during our Smart Simulation Summit in Michigan, 2022. The challenge, he explained, is that designers often don’t have enough information to create designs that are optimal for manufacturing. Instead, they rely on rules of thumb and the precedent of what was applied on the previous platform. The issues become obvious by the time production begins, when it is too late and too costly to make the desired changes.

As the automotive industry evolves to become more agile and simultaneously scale up electric vehicle (EV) production, this problem is likely to become even more acute. There is recognition that the ongoing transformation of the automotive industry toward Industry 4.0 is now a necessity, which presents an opportunity to revisit the core concepts of automotive design and build more optimal and sustainable vehicles that take advantage of new technologies. Virtual assembly is a new approach that applies proven simulation technologies to help drive this transformation from the design phase and reduce costly surprises.

While the traditional manufacturing process from design to production can be drawn as a linear workflow, it is often more complicated in practice because the teams involved work in departmental silos using the best information they are given. There are very few tools and processes that enable effective communication between manufacturers and product development teams.

A new vehicle development cycle ranges from an average of three to five years, while the prototype and testing phases span between six months and 12 months depending on the complexity of the vehicle. To cut time and associated cost, automotive OEMs are actively working to reduce the number of physical prototypes to as close to zero as possible. Ideally, every single manufactured piece should be part of a sellable product. New players who started very lean achieved rapid innovation and shortest time to market by heavily relying on virtual prototyping.

Because it is done digitally, information can be readily shared and stay up to date for a truly collaborative engineering process. Every large OEM and much of the supply base are already moving toward zero physical prototypes with varying degrees of pace. General Motors, for instance, has announced its intent to achieve 100% virtual validation by 2025. This goal results in an even more challenging requirement for vehicle design, as some trial and error are typically required to achieve a final design that can be consistently manufactured at scale.

Physical testing and try-outs have been the only methods available to ascertain manufacturability and validate system or assembly success post-integration. However, to create and test a physical prototype, components must be physically produced to sufficient quality. This in turn requires a significant time and investment in soft tooling for stamping/forming processes and in fixtures for assembling the components. Prototyping hence becomes one of the costliest phases in the product development process — from the point of view of cost, time and sustainability.

The Power of Virtual Assembly

Virtual assembly serves as a powerful tool within the realm of vehicle manufacturing by seamlessly integrating the physical aspects of production with the virtual realm of engineering design, creating a single digital twin. By creating accurate digital models of the manufacturing process, OEMs can also simulate production before physical manufacturing begins. This reduces the necessity for physical prototypes and enables manufacturers to identify and address issues earlier in the value chain.

By integrating virtual manufacturing with virtual design prototyping, designers and manufacturers can create a comprehensive digital model of the product “as manufactured” and its assembly processes. This also facilitates greater collaboration among stakeholders, enabling them to work in their field of expertise while working collaboratively toward shared goals using the same dataset. This enables all parties to identify and address issues across the value chain, improving quality, reducing waste, and expediting product launches with fewer unforeseen challenges.

Let’s use the resistance spot welding (RSW) process as an example. Widely adopted in the automotive industry, RSW offers advantages such as lower cost, rapid execution, and compatibility with automation. However, because the process involves melting metal and solidification, deformations within the resulting fabricated structure don’t adhere to straightforward linear relationships. This becomes even more pronounced when assemblies incorporate new materials, such as GEN3 advanced high-strength steels.

Traditionally, welding process design heavily depends on operator experience and a time-consuming trial-and-error approach, leading to inefficiency and high costs. Here, finite element analysis (FEA)-based welding process simulation has emerged as a valuable tool for many manufacturers. It aids in designing optimal clamping, fixturing, and welding processes by predicting intricate distortions. By enabling pre-emptive compensation during the design phase, FEA-based simulations mitigate these challenges before the construction of the initial prototype.

Virtual assembly amalgamates manufacturing process simulations, hitherto employed for part production, into a unified spatial model that enables teams to proactively address non-optimal and potential integration issues within the final assembly. This amplifies the advantages of part manufacturing simulations, thereby ensuring a more streamlined production process, more optimized overall design, and an improved product lifecycle.

It establishes a single version of data integrity throughout the design and manufacturing process, facilitating a comparison between the virtual (as designed) with the physical (as manufactured) that expedites the maturation of novel processes through swift feedback and iterative enhancements. Notably, the focus of this solution goes beyond just automation, as we aim to empower all stakeholders by allowing them to extract richer insights from the data. These insights span critical tolerances, process steps and durations, as well as total manufacturing costs.

The time for a bold new approach is now. A paradigm shift toward entirely eradicating BIW (body in white) prototyping in the development of new vehicles requires novel strategies for both scaling production and minimizing manufacturing uncertainties when bringing these vehicles to market.

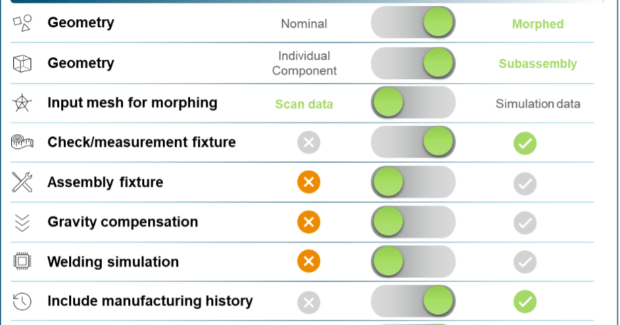

At Hexagon, we are actively contributing to this endeavor by leveraging the recently unveiled Nexus digital-reality platform and seamlessly integrating our class-leading multi-physics manufacturing process simulation capabilities with precise metrology data to better translate the intricate interplay between design and manufacturing processes. Departing from the conventional reliance on nominal product geometry, for example, we are employing metrology data from physical parts to dynamically adapt simulation meshes, ensuring congruence with real-world scenarios. This empowers manufacturers to accurately prognosticate the behavior of assembled systems across subsequent phases such as fixturing, welding, and other assembly processes.

Virtual assembly enables our customers to plan processes from end to end and to answer questions such as, “Is this the right fixture for the measurement I want to perform?” and “How will the clamps or deflection resulted from gravity affect measurement?” It also helps manufacturers identify where assembly problems arose — precisely which station, weld, and clamp caused the problem, as well as when the problem occurred.

These powerful tools help manufacturers predict and resolve assembly challenges before production, which is a key step toward virtual validation. An effective virtual assembly solution’s primary advantage lies in its capacity to — through tailored language and an effective user interface that enhances data comprehension and fosters cohesive improvement — provide stakeholders with role-specific information when and where needed.

In the wake of siloed processes, the dawn of Hexagon’s collaborative virtual assembly solution marks a pivotal moment in automotive manufacturing. This transformation promises heightened overall productivity and charts the path to greater manufacturing sustainability and enduring excellence.