The Next Generation of Machine Tending Has Arrived

Machine tending solutions safely expand the reach and payload capability of cobots.

Posted: September 29, 2023

Expanded reach and the ability to handle heavier loads doesn’t equal heavier cobot solutions. Lightweight and durable cobots are able to reach into tight spaces safely and efficiently.

The Future of Cobot Automation

KUKA’s (Shelby Township, MI) LBR iisy cobot is ready to use automation that quickly and easily integrates into any manufacturing application from pre-defined production processes to open, unstructured work environments. With six axes, a 3 kg payload, 600-mm maximum reach and 18.8 kg overall weight, the LBR iisy is well suited for overcoming the challenges posed by confined workspaces. The LBR iisy is also available in 11 kg and 15 kg payloads.

Whether loading/unloading machines, assembling components or packaging, the cobot provides increased versatility and can be immediately operated by anyone from an automation expert to a cobotics newcomer. The integrated cables and power supply of the LBR iisy ensure quick and easy tool changes, while the compact footprint with the small KR C5 micro controller means it will fit into almost any space and the safety features allow for fenceless operation. The LBR iisy is fully embedded into the KUKA Industry 4.0 ecosystem.

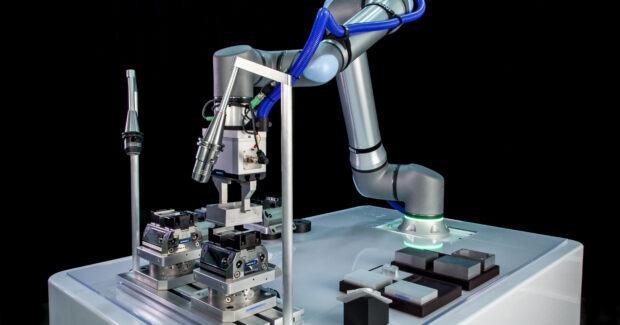

Resigned Cobot is Lightest in Its Class

Universal Robots (Ann Arbor, MI), the leader in collaborative robotics, offers an all-new 20 kg payload cobot, the UR20, which has been reimagined, redesigned and rebuilt. Every detail from software to end caps has been strategically built to deliver next-generation performance and quality. The UR20 is not just a bigger version of existing UR cobots; it’s the cobot redefined, boasting a new joint design that increases all joint torques approximately 25%, and joint speeds by as much as 65% with an increase in TCP speed of 100% (2 m/s vs. 1 m/s). The UR20 can handle up to 20 kg with a reach of 1,750 mm. It’s the lightest robot on the market in its payload and reach class, weighing only 64 kg with a small footprint (Ø 245 mm).

The UR20’s reach introduces the capability to work in large-scale workplace setups, making it a perfect fit for many tasks in metal fabrication such as stamping, cutting, press tending, grinding and welding.

Line of Grinders Optimizes Automated Machine Tending

Weldon Solutions (York, PA), which provides world-class CNC cylindrical grinder products, robotic automation systems and technical support, is excited to offer the AGN4 line of CNC grinders. In this application the highly customizable model AGN4 is part of a precision valve seat grinding system which incorporates a full Weldon turnkey system consisting of a grinder, a 6-axis machine tending robot, a dual pallet infeed system, coolant filtration, mist collection, in-process gaging and CBN superabrasives.

An angular wheel approach is used to permit grinding the OD and the valve face in a single plunge. The fully automatic cycle under gage control will achieve an average production rate of 110 parts per hour and maintain SPC at 2.0 Cpk on all critical attributes.

In a different approach to part queuing, this grinder utilizes vitrified CBN superabrasives to precision grind solenoids in a two-operation process to length, flatness, parallelism, and surface finish specifications. Machine tending is accomplished using a FANUC LRMate Robot and Weldon’s multi-drawer part storage system.

Weldon recently expanded our facility to accommodate new business. If you are seeking custom-built grinding systems for your operations, contact us for the solutions you need.

Subscribe to learn the latest in manufacturing.