Robotics and Automation in the Driver’s Seat

No programming, AI and safer robotic and automation solutions aid in overcoming the skills gap in the metalworking industry.

Posted: September 29, 2023

Your shop has made the decision to implement or upgrade automation and industrial robotic solutions. These cobots, robotic tooling and sensing, and customizable and innovative software solutions offer efficiency and the highest levels of safety. What’s more, these solutions perform repetitive activities which reduce day-to-day operational costs, and boost productivity.

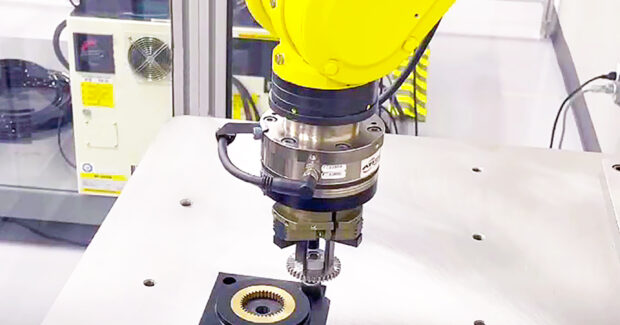

Multi-Axis Force/Torque Sensors now Compatible with FANUC Robots

ATI Industrial Automation (Apex, N.C.), a Novanta company, and a leading provider of robotic tooling and sensing solutions, announces the compatibility of its Multi-Axis Force/Torque (F/T) Sensors with FANUC robots and FANUC’s Force Control Software. This collaboration opens up new possibilities for advanced automation and precision control in robotic applications. This integration brings enhanced sensing capabilities to robotic systems, enabling users to achieve greater levels of accuracy, flexibility and responsiveness.

ATI’s Multi-Axis Force/Torque Sensors are renowned for their ability to provide accurate measurements of forces and torques in multiple axes, enabling robots to have a sense of touch and allowing them to perform delicate tasks with dexterity. These sensors are designed to withstand harsh industrial environments, ensuring reliable operation in a wide range of applications. Whether in research, medical applications, industrial operations, or even extra-terrestrial missions, ATI force sensing technology is revolutionizing the way robots interact with the world.

By combining ATI’s advanced sensing technology with FANUC robots, known for their industry-leading performance and reliability, users can now leverage the full potential of force control in their robotic operations. FANUC’s Force Control Software allows for precise control of robotic motion based on real-time force feedback, facilitating tasks such as assembly, deburring, polishing, and material removal with unparalleled accuracy. Target industry segments include metal fabrication, automotive, aerospace, electronics assembly, semiconductor and general industry.

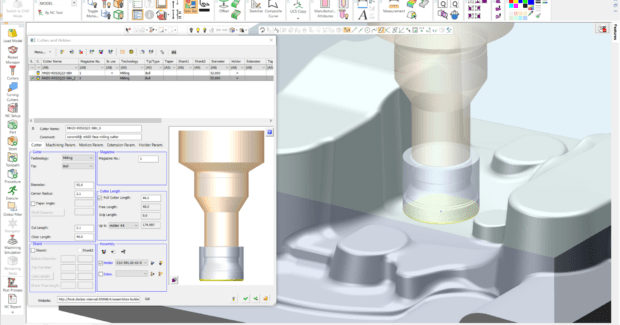

New Version of CAD/CAM Software is Unparalleled for Advanced Toolmaking

Cimatron (Cincinnati, OH), part of the Sandvik Group, and the leading CAD/CAM software supplier for the mold and die industry, has released version 2024 with stronger core capabilities across all areas of the product, while incorporating new technology through collaboration with Sandvik Coromant. Cimatron 2024 simplifies and automates many tasks for tool designers for higher productivity, and more options for digital connection.

There are several advanced user workflow updates including multi-view spacing, batch-processing for drawing updates, tangent control for blending faces, and an easy option for capping internal islands. CAD users will enjoy many new features for 2D drafting as well, such as importing PDFs as real geometry and text, new minimum distance dimensioning, enhanced symbols, and improved geometric datum and tolerancing. There is also a clean new GUI for controlling drafting standards, improved draft analysis visualization, and automated chain selection of chamfer faces.

Mold makers gain powerful CAD enhancements for rib construction with added functionality for working on multiple curves in a single operation and automatically extending rib geometry to part side walls. Cimatron 2024 can now create partial ribs in complex scenarios where a complete rib cannot be produced.

Electrode design is a critical aspect of the mold production process. Version 2024 includes automation for the Burn Body operation to optimize the electrode body shape, control of electrode extensions, and non-cutting rules for manual construction.

Die designers can now easily build 3D drawbead geometry to control material flow during the drawing operation to achieve the optimal forming of a part without cracks and wrinkles. The new routine will generate the drawbead based upon section type and automatically blend the result into the binder faces.

Cimatron 2024’s Enhanced Automatic Feed Control routine has been completely redeveloped and optimizes stock removal for roughing operations by automatically controlling the feed rate, resulting in smoother motion, faster machining times, longer tool life and fewer changes on the machine spindle and axes. Live benchmark testing with Sandvik Coromant has reduced cutting time more than 10% on CNC machines.

For 5-axis machining, the software now allows the automatic use of remaining stock from previous 3-axis operations during roughing. This enables the use of shorter cutters for greater stability.

In terms of CAM advancements, Cimatron 2024 introduces several notable features. For example, the On Machine Inspection Probing module now supports multipoint selection and cylindrical-shaped probes, enabling more versatile and precise inspection processes. The improved toolpath simulator calculation time results in an average productivity gain of more than 30%.

Cimatron 2024 unlocks the power of Sandvik Coromant by establishing direct integration with the CoroPlus® Tool Library and TDM tool management system. Users gain access to a vast collection of more than 900,000 cutting tool items, with the system making intelligent tool recommendations based on material, operation and tool type. This integration optimizes the machining process, delivering better results without the need for manual data entry.

New Configurable Small Controllers

Pilz (Canton, MI), the machinery safety automation company, has introduced the PNOZ m C0 unit, which is just 22.5 mm wide and monitors up to four safety functions on machines. Depending on the application, the new base unit enables high productivity on smaller machines and can be used to implement safety requirements up to the highest category PL (performance level) e or SIL CL 3. It is ideal in various industries and application areas, such as packaging, robotic cells and the food and beverage to name a few.

The extremely narrow PNOZ m C0 has the structural properties of a safety relay but is as powerful as a configurable safety controller. It provides eight safe inputs and four safe semiconductor outputs, and up to four safety functions can be reliably monitored. These include E-STOP, safety gates, safety light curtains and two-hand control.

Also on this standalone base unit, all safety circuits are created via the intuitive software tool PNOZmulti Configurator, the basic version of which is free of license costs and available on the Pilz website. From Version 11.1, individual safety requirements can be implemented simply and flexibly. The tool provides several approved software blocks for monitoring safety functions up to PL e/SIL CL 3. All created safety architectures can be used independently of a PLC controller, so the safety circuit can be downloaded to the device directly via a USB cable and either saved directly or, alternatively, on the chip card. Digitally supported engineering minimizes configuration time and therefore costs for this step in the life cycle.

What’s more, functions can be expanded or modified at any time.

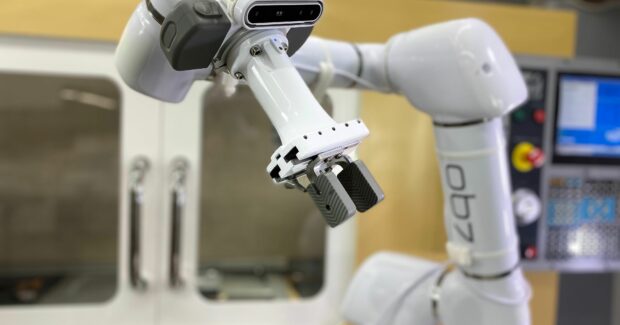

7-Axis Cobots Take Over Repetitive Tasks With no Programming Needed

Reshoring, part diversification and the need to bridge the skills gap have prompted fabricators and job shops to look for ways to boost production efficiencies while reducing day-to-day operating costs. Productive Robotics’ (Santa Barbara, CA) 7-axis, augmented intelligent OB7 cobots improve quality and speed up production rates by automating welding tasks and repetitive processing activities.

At the recent FABTECH 2023 event, the company demonstrated its Blaze stand-alone, single station and two-station welding systems, as well as CNC milling, deburring, grinding and gluing. Attendees were able to test Productive Robotics’ proprietary, no programming user interface by teaching OB7 a job in just seconds. “We believe cobot programming is only easy for programmers, so we eliminated it entirely,” said Zac Bogart, president of Productive Robotics. “This allows us to remove barriers like complex integration, high costs and programming and put budget-friendly advanced robotic automation into the hands of small job shops and large manufacturers. We’ve engineered our cobots to perform a diverse number of pick and place activities and highly repetitive jobs for industries that range from medical device and food and beverage to miscellaneous metals and machinery.”

To automate OB7, fabricators can add a Productive Robotics parallel electric gripper/end effector, patented robot rolling stand and worktable. The cobot is also compatible with other grippers, cameras and accessories. Data collection is supported by Productive Robotics’ cloud analytics system making it easy for small- to medium-sized job shops to implement real-time reporting on cobot activity. Installation of the OB7 can take approximately two hours.

Productive Robotics’ augmented intelligent machines — the OB7, OB7 Stretch model, MAX 8 and MAX 12 — are the only cobots on the market designed and built in the U.S. The plug-and-play machines are engineered to work with new or legacy equipment and have the flexibility to perform both simple and complex activities.

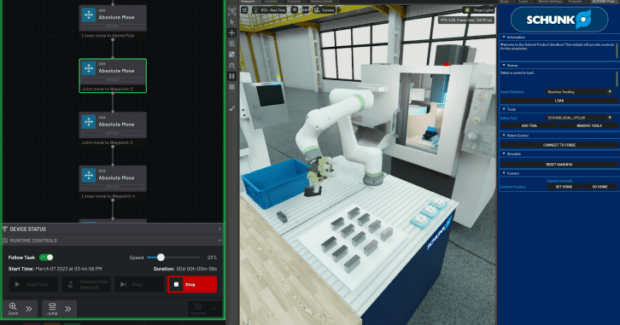

New Partnership to Develop Automation Explorer Simulation Tool

SCHUNK USA (Morrisville, NC) has partnered with READY Robotics to develop the Automation Explorer simulation tool. As automation technology advances, simulation technology must progress further to support specification, deployment, and re-deployment of automated systems. Automation Explorer is a state-of-the-art technology where users will virtually experience and interact with SCHUNK automation technology in a highly immersive and detailed, physics-based simulation tool.

NVIDIA Isaac Sim™, built on NVIDIA Omniverse™, is a simulation platform used to develop, test, and deploy AI-based robotics applications. Its robust physics engine enables detailed, realistic simulations that closely emulate real-world conditions. READY Robotics is the developer of ForgeOS, the industrial OS for robots and automation, and a pioneer in cutting-edge automation solutions. Automation Explorer combines NVIDIA Isaac Sim, READY Robotics’ ForgeOS, and SCHUNK’s automation technologies.

Automation Explorer will take the term “digital twin” to the next level. Photo-realistic imaging of manufacturing environments, advanced robot control software, and world-class automation technology come together in one unique experience.

Physics-based technical product data from automation technology, like grippers, will drive the simulation. This allows true virtual commissioning of real-world automation projects. Simulating process automation with physics-based calculations means more accurate visualization and optimization before a robot ever reaches a production floor.

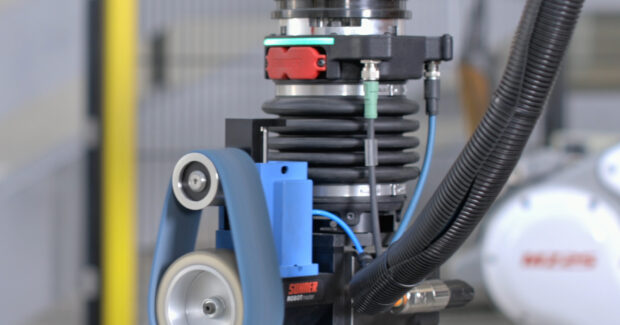

First Fully Electric Force Compliance System Ensures Repeatability

Suhner USA Inc.’s (Rome, GA) new EFC-02 combines a century of Suhner’s abrasives and material removal expertise with smart robotics. The fully electric EFC-02 active compliance device connects a grinding machine to a robot and delivers precise, constant force throughout robotic grinding, sanding and deburring processes.

Featuring Industry 4.0 standards, the device features simple robot programming using a web-based interface or fieldbus communication. It also features LED indicators to note if the grinding wheel is at its minimum or maximum limits, or when the stroke is within the window set by the user.

In development for three years, the EFC-02 assists customers by providing a solution that allows them to do more with fewer resources. “We looked at the next thing we could do for our customers and that was a compliance device,” said Juan Martinez, an engineer with Suhner USA. “One of the ways we wanted to stand out was to be fully electric.”

Ideal for light- to medium-duty applications where repeatability, accuracy and reliability are crucial in the material removal process, the EFC-02 is suited for industries such as food and pharma, mold and die, aerospace, automotive, foundry and others. With its adapter plate, the EFC-02 can be mounted to just about any robot brand. “We like to say that we are robot agnostic,” Martinez said.

The EFC-02 requires just two connections: a 48-volt power supply and a communication cable, which is done through M-Bus TCP. During the design phase, Suhner’s engineers ensured the device was as compact as possible so it could access tight spaces. It is 198 mm in maximum length, which considers the 20 mm of working stroke. It weighs roughly 4.05 kilos or 8 pounds — that includes the adapter plate.

Speaking to the device’s repeatability and consistency because it is fully electric, as you reorient the EFC it takes into account payloads. Said Martinez, “So, whatever you attach at the end of the EFC, the orientation might be upright at first but as you reorientate upwards, downwards or to the side, it can tell where its position is, and you can start to compensate for that weight at the end of it and the force it can provide.”

Being fully electric, the EFC-02 provides a more repeatable process compared to pneumatic lines because compressed air is not always reliable and requires an additional line. Suhner’s device can be connected to the robot without those additional lines. “Not only that, the customers like the instant feedback because you get to see automatically the response in the position of the EFC, and also the amount of force that it is actually applying.”

One customer saw the potential added value the EFC-02 could provide by overcoming their difficulty in reaching a part from its underside. In other devices, the robot would have to be programmed to go underneath the part to attack the polishing, grinding or whatever process was needed. With Suhner’s device, not only is a positive 200N (newton) force applied, but the device can also retract and apply a negative force, Martinez noted. “Instead of going underneath the part and applying the force, the customer would be able to go over the part and just pull and apply the force in that way,” Martinez said.

Moving forward, robots and compliance devices will shape the future of manufacturing, particularly when it comes to repeatability and consistency in the finishing process.

www.robotic-grinding.suhner.com

Subscribe to learn the latest in manufacturing.