Master the Quick Change: Speed up Your Shop’s Cycle Time

Enhance your cobot’s versatility with lightweight, automatic tool changers that include several configuration options.

Posted: September 29, 2023

Robotic tool changers offer a range of solutions, are compatible with a variety of cobots, and even offer blank robot and tool plates to customize mounting patterns.

Robotic Tool Changer is a Feature-packed Solution

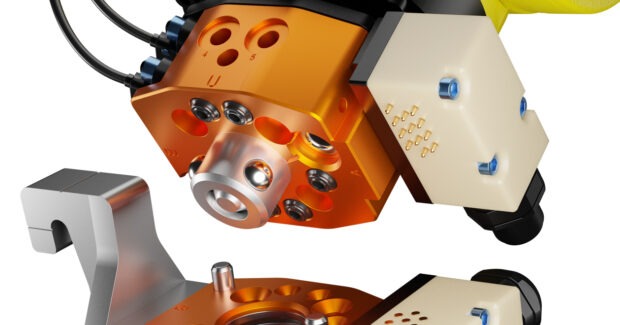

ATI Industrial Automation (Apex, N.C.), a Novanta company, has developed a new standard robotic tool changing and storage solution: the QC-7 Robotic Tool Changer. This lightweight yet durable tool changer offers a variety of configuration options with ATI’s Pass-Through Utility Modules and Tool Stand systems. An optional ML12 Electrical Module attaches easily to the QC-7 Robotic Tool Changer body, which also includes five pass-through air ports and lock/unlock air fittings.

The QC-7 Robotic Tool Changer features a low stack height and mounts directly to ISO 9409-1-31.5-4-M5 robot wrists. This tool changer is compatible with ATI’s modular tool stands and has an optional tool storage hook to make robot programming easy.

The pneumatically actuated QC-7 features no-touch locking technology and a patented fail-safe locking mechanism for a secure connection between the master and tool. The design integrates lock/unlock sensors without the need for an additional interface plate. This tool changer handles payloads up to 35 lbs. (16 kg) and is compatible with a variety of industrial and collaborative robot models.

Simple Off-The-Shelf Cobot Tooling Solutions

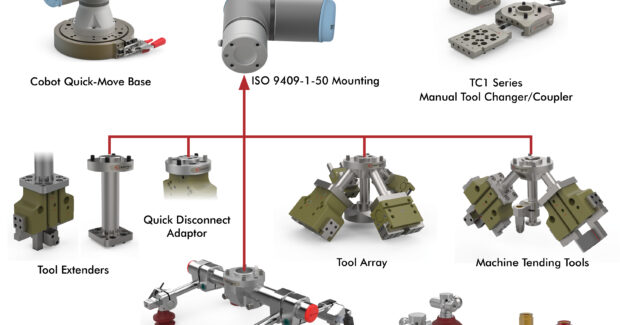

DESTACO (Auburn Hills, MI) offers cobot tooling solutions that are designed to simplify tool selection and eliminate integration design work for applications employing small payload robots or cobots in their operations. The wide variety of tooling solutions is designed for gripping, palletizing, machine tending, tool changing, and tool extension applications up to 10 kg payloads.

“Small payload robots are commonly found in larger industrial-manufacturing facilities, but there has been significant growth recently in their use in small light industrial and commercial shops due to the low-cost entry into robotic automation,” said Gary Labadie, global product director for DESTACO. “This low cost entry into robotic automation is now a focus and a solution for both large and small facilities coping with the economic climate.”

The fast growth in the cobot market is driven by a number of factors, including increases in inflation rates, labor costs, labor shortages and excessive workforce turnover. The low startup costs for new entrants into the automation industry and a relatively compact return on investment period for a cobot system, which can be as few as eight-to-12 months, make DESTACO tooling solutions attractive to users.

DESTACO has designed its cobot tooling solutions for simplicity and ease of use with off-the-shelf availability via kits that feature all of the end-user selected accessories, along with the hardware and tools needed for installation, reducing the need to consult an application engineer. All of the tooling solutions are compatible with cobots that have an ISO 9409-1-50-4-M6 end-of-arm mounting pattern. Blank robot and tool plates are offered for those who wish to use their own mounting patterns.

A standout feature in DESTACO’s suite of cobot tooling is the Microtool End Effectors that enable the cobot to perform palletizing functions. Users that know the length, width and weight of the packages to be lifted and transferred can easily select the palletizing kit type and pre-determined vacuum cup size necessary for the application eliminating tool design work with off-the-shelf kits.

Subscribe to learn the latest in manufacturing.