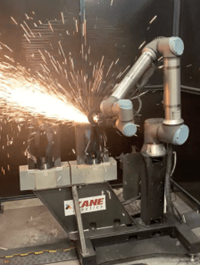

Kane Robotics to Demo the First Purpose-Built Weld-Grinding Cobots at FABTECH 2023

The first-mover cobots double the productivity of grinding welds. GRIT liberates technicians from the grueling, often hazardous chore of manual grinding and finishing.

Posted: September 4, 2023

FABTECH 2023 attendees will witness a monumental leap in collaborative robot technology when Kane Robotics showcases its GRITTM at North America’s paramount event for metal forming, fabricating, welding, and finishing.

The unveiling will take place Sept. 11-14 in Chicago’s McCormick Place at the booths of Universal Robots (UR) (#B17063) and ATI Industrial Automation (#B31027).

Launched in April 2023, GRIT is the first accessible automation solution proven to double weld-grinding productivity. Equipped with the precision of a UR10e robotic arm, ATI’s CGV-900 Compliant Angle Grinder, and 3M’s Cubitron II abrasive media, GRIT liberates technicians from the grueling, often hazardous chore of manual grinding and finishing.

Kane engineers will simulate GRIT’s precision process, which grinds welds at twice the speed of human technicians, improving material removal productivity by as much as 50-80%.

Beyond the significant increase in output, the practical, low-cost cobot solution reduces workplace safety concerns and assists with labor shortage challenges plaguing small- and medium-sized manufacturers. Unlike traditional industrial automation, GRIT is reconfigurable for a wide range of sanding, grinding, and finishing tasks while maintaining an affordable price point that yields a 100% return on investment within months.

In recognition of Kane’s innovation and GRIT’s agility to solve productivity problems for industries across diverse verticals, UR is considering the cobot for its UR+ ecosystem, reserved for its most trusted partners.

Join Kane at FABTECH 2023 and say goodbye to grinding and sanding like robots and hello to collaborating with them.

About Kane Robotics

Since its founding in 2019, Kane Robotics has collaborated with manufacturers to simplify material removal processes through automation, creating the first collaborative robots (cobots) explicitly built for composite sanding and weld grinding. Kane’s reconfigurable and easy-to-operate cobots work alongside humans to perform safe and precise sanding, grinding, and finishing. The compact, mobile, and affordable cobot solutions are accessible to all sizes and types of manufacturers and offer a pragmatic way to dramatically increase productivity, improve safety, and fill job vacancies for dangerous, repetitive, and labor-intensive tasks. Kane’s industry experts are considered some of the top minds in the world for automation in sanding and composites.

About Universal Robots

Universal Robots is a leading provider of collaborative robots (cobots) used across a wide range of industries and in education. Founded in 2005 and headquartered in Odense, Denmark, Universal Robots aims to create a world where people work with robots, not like robots. Its mission is simple: Automation for anyone. Anywhere. Since introducing the world’s first commercially viable cobot in 2008, Universal Robots has developed a product portfolio reflecting a range of reaches and payloads and has sold over 75,000 cobots worldwide. An extensive ecosystem has grown around the company’s cobot technology creating innovation, choice for customers and a wide range of components, kits and solutions to suit every application. The company has over 20 offices globally, with North America headquarters in Novi, MI.

About ATI Industrial Automation

ATI Industrial Automation is the world-leading, engineering-based developer of robotic accessories and robot arm tooling, including Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Utility Couplers, Material Removal Tools, Robotic Collision Sensors, Manual Tool Changers, and Compliance Devices. Their robot end-effector products are found in thousands of successful applications around the world. Since 1989, their team of mechanical, electrical, and software engineers has been developing cost-effective, state-of-the-art end-effector products and solutions that improve robotic productivity.

Subscribe to learn the latest in manufacturing.