Joining Forces: Tech Trends Shaping Robotic Welding

Adopt technologies that handle market pressures and empower workers to ensure your long-term success.

Posted: September 29, 2023

Under constant pressure to increase production throughput without compromising quality, manufacturers continue to implement robotic automation. Ideal for adding capacity to shop floor or assisting with manual weld processes, fast and reliable robots with intuitive programming capability are addressing tough challenges.

Arc Welding Advances

Expected to grow at a compound annual growth rate (CAGR) of 4.9% between now and 2030, the global market for arc welding equipment continues to thrive1. Much in part to the growing segment for sustainable energy, this usage will prompt an uptick in robot utilization for arc welding, especially with new welding requirements for electric vehicle battery manufacturing. To accommodate unique requirements for this segment and others, innovative companies are developing user-friendly tools for:

- Weld Monitoring and Control

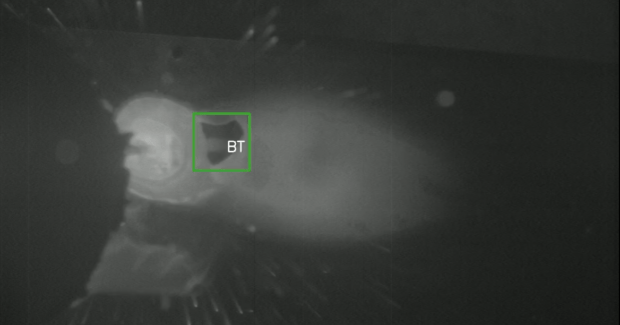

Harnessing the power of Artificial Intelligence (AI) and smart vision systems, groundbreaking weld monitoring and control systems, such as NovEye™, can now help a robot adapt a programmed path based on the characteristics of the weld puddle. Capable of automatic tack detection, as well as root pass seam tracking and gap measurement, systems like these combine intelligent image processing with state-of-the-art AI algorithms and advanced robotic controls to fully automate the welding process. Originally used in pipe welding, the addition of six degrees-of-freedom to this technology expands the possibilities for heavy deposition welding, and potentially, the welding of complex parts in the near future.

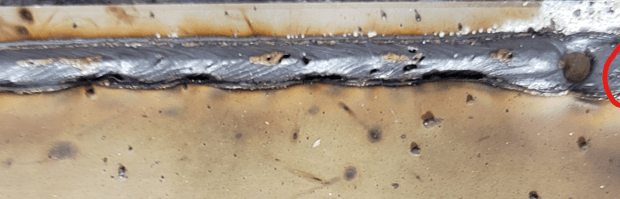

- Single Power Supply, Dual-wire Process

To add simplicity or power to the arc welding process, power supply companies are dialing-in on creative ways to help manufacturers. From utilizing lasers to new techniques to control heat input, new part types being joined at high speeds require new solutions. One effective way is through a dual-wire process, known as HyperFill™. Patented by Lincoln Electric®, this method utilizes two smaller diameter wires to produce a larger weld droplet and arc cone, generating a large weld puddle that is easier to control. By only using a single power source, feed, gun liner and contact tip with a familiar robot pendant interface, this promising method offers the potential to increase usable deposition rates up to 50% over traditional single-wire usage in robotic processes.

- Part Testing and Inspection

Offering capability and consistency that humans and coordinated measuring machines cannot, the use of high-performance robots and welding power supplies paired with innovative vision technology, sound sensors, machine learning and data analytics are advancing the part testing and inspection process. Companies such as IBM® and Yaskawa are teaming up to champion this utilization – enabling a high-resolution thermal camera to capture data on the live weld pool, while the sound of the weld is also recorded. All data collected combines to create a weld score for the utmost quality, preventing large amounts of scrap parts and stopping bad welds from infiltrating the field to ensure 100% sampling on inspections.

- Collaborative Welding

Whether it is to supplement the manual welding process, to assist with the welding of large workpieces or to add capacity to current production for high-mix parts, the use of highly flexible and lead-to-teach collaborative robots designed for use in harsh environments continues to grow. Extremely portable weld carts with minimal features and a single cobot, as well as complete pre-engineered collaborative welding systems with additional safe-guarding like fume extraction, are readily available to fulfill unique production requirements where human-robot interaction may be required. Keep in mind to thoroughly assess the risk of the entire robotic system (i.e., robot, workpiece, workspace, end-of-arm tooling, environment, etc.) for each application to ensure the utmost safety.

Spot Welding Advances

Robotic spot welding process continue to benefit from advances. From the use of mid-frequency inverters for DC welding and higher frequency inverter switching, to servo spot guns integrated with the robot controller for easier programming, robot uptime is being increased, cycle times are being minimized and product quality is being enhanced. Recent focus has centered on:

- Optimization Functions

High-performance robot interfaces come with a plethora of helpful features to boost productivity and weld quality. From position related functions, such as Gun Equalization, Tip Wear Compensation and Workpiece Thickness Detection, to torque associated functions like Controlled Clamping Pressure, Automated Weld Sequencing with Pressure, Workpiece Search Function and more, there are multiple proven features to facilitate a controlled spot welding process.

More recently, where aluminum welding is concerned, the use of Pressure Compensation Function is gaining notice. Providing the ability for an outside value to change spot gun pressure, this function allows bias to be set for a program value in the pressure file. At times, manufacturers take the concept of pressure compensation a step further by utilizing Force Forging – a time function that involves applying additional pressure to the welding electrodes during the weld sequence. To accommodate this, a strain gauge is added to the spot gun(s) to monitor the force profile and spot parameter data, allowing the spot gun to sense when the material is hitting a plastic or molten state. This prompts the weld timer to trigger the additional “forge force” or clamping pressure required as the nugget forms and effectively seals the weld at the opportune time for improved weld integrity.

With respect to weld timers, they can also help monitor gun pressure with the addition of a strain gage, while the robot provides feedback on the gun pressure. Used to monitor spot gun pressure, the Pendant Oscilloscope Function is a tool used to track the speed and torque of each robot axis, as well as an external gun axis, on an oscilloscope, when needed. Ideal for also checking the status of spot welding signals (i.e., weld control signals for start and end of the weld), this function is very helpful in verifying or trouble shooting proper weld timing. Note: the robot signals can be exported to a database where monitoring software can store and analyze the results over time.

- Device Management

With device monitoring in mind, robots and their connected devices (i.e, grippers, scanners, torches, etc.) can provide a wealth of data pertaining to equipment performance and operational trends. Moreover, transforming this info into actionable insights can be key to optimizing production and part quality. For spot welding, the servo spot gun can be monitored to watch for changes in plate thickness, as well as to keep track of the spatter occurrence rate for each job.

The implementation of a factory automation monitoring system that supports multiple brand devices and collects data in real time is ideal for facilitating this – as these platforms can be used to look up and determine the point of failure when product quality decreases or severe defects are found. Proven edge server solutions are ideal and use a leading OPC-UA interface to enable an integrated, intelligent and innovative approach to data analytics.

In conjunction with these technologies, other tools Such as pendant applications, like the Universal Weldcom Interface, continue to allow robot users to gain easy control of any weld process or parameter, Ease-of-use interfaces with intuitive capabilities empower companies to automate their production floors regardless of their hardware. These platforms offer a PC-based, click-and-drag approach to program the robot movement.

Overall, companies that adopt these technologies will be better poised to handle market pressures.

1 Arc Welding Equipment: Global Strategic Business Report, Research and Markets, 2022

Subscribe to learn the latest in manufacturing.