Formdrill-USA Turns New Ideas into Pioneering Solutions

Formdrill’s friction drilling is a nearly 50-year-old proven and cost-effective alternative to costly weld nuts or inserts traditionally used to create threads in thin-walled metal materials.

Posted: September 29, 2023

If you are using weld nuts or inserts to create threads in thin-walled materials in metal manufacturing processes, there is a strong, high-quality connection alternative tool that many fabricators in the United States are not familiar with — even though it has been around for decades.

One leading legacy automobile OEM’s engineering team was so impressed with Formdrill-USA Inc.’s (Rolling Meadows, IL) presentation on the thermal drilling system that the engineers were under the impression it was a new technology. It was only then that the OEM’s team learned they had actually been using the process in their plants for decades.

“We conducted a presentation to 12 engineers at the main home office of this company and they were like: ‘we can use this here, and we can use this there,’” said C. Todd Bieri, vice president of operations, Formdrill-USA Inc. “Once they realized we are a solution to making a hole and creating a bushing in thin-walled materials that can then be threaded, it triggered a chain reaction of thoughts on where else they could use the process. We continue to work with them in different aspects, including in the foot pedals in one of their applications.”

Formdrill uses a thermal drilling process that relies on friction heat to produce bushings in metal tubing and flat stock. There is no cutting involved for the creation of the hole, which is made out of the material itself. The formed bushings can also be used as a through hole for welded, soldered and brazed connections. Or they can be used for a load bearing surface, for example in U-joints. Formdrill’s tools are made of special sintered carbide, which is then ground into a Formdrill friction drilling tool.

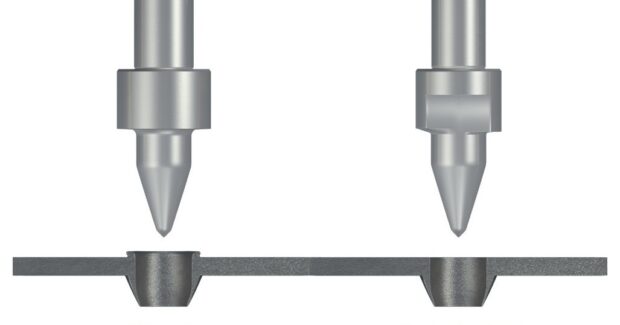

There are two steps to the Formdrill process:

- First, a bushing is created out of the parent material using a Formdrill tool and your own equipment. The length of the bushing is roughly three times the original material thickness.

- Second, tap with a Formtap tool to create strong threads in the bushing.

Your product is now ready for assembly.

“Our drills use friction, and they plasticize any malleable material such as steel, stainless steel, aluminum, copper and brass, and high-strength steels,” Bieri said. “It forms an insert out of the material itself.”

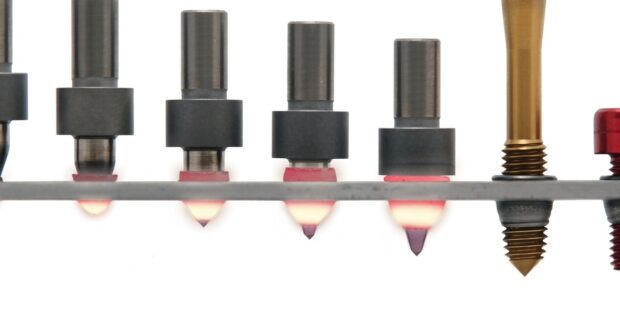

This thermal drilling system from Formdrill can be used with material thickness ranging from 1.0-to-12.0 mm (0.040″-0.500″) depending on the diameter of the hole. Short styles are used in thinner materials; longer styles are used for thicker materials and for straight through holes. Short/flat or long/flat styles remove the upper portion of the bushing for a flush flat surface finish.

A variety of industries benefit from implementing Formdrill’s thermal drilling system such as multi-national companies in the automotive, heating and cooling, medical equipment, building structural frameworks, road lighting and signal fixtures and metal furniture manufacturers. Automotive applications include mounting brackets, battery trays for electric vehicles, steering columns, suspension arms, seat frames, seat rails, brake systems and shock absorbers.

The process also works well in automated manufacturing processes because it is a chip less process that produces accurate holes and offers a long tool life, Bieri noted. Tool life is between 8,000-to-10,000 cycles in steel; and between 3,000-to-5,000 cycles in stainless steel.

No Additional Equipment Required

One of the advantages of Formdrill’s process is that no special machinery is required to implement the Formdrill line of tools; they will work on any drill press that has the required spindle speed, motor power and axial force to push the tool through the material. Items needed to start with the Formdrill thermal drilling process include your own equipment, a tool holder, a collet, the Formdrill tool, the Formtap tool and lubricants.

“You can use your own equipment, including milling machines, CNC-machining centers, drill press [hand or automatic feed], CNC-pneumatic or hydraulic units — all are suitable for the process,” Bieri said.

Formdrill offers standard tools in four different styles, ranging from 1.8-to-25.4 mm (0.070”-to-1.000”) in diameter. The Formtap tools displace material and generate threads; conventional machine taps are unable to do this. The Formtaps are a roll forming style tap used to maximize thread strength and pull-out resistance. They turn as much material as possible into threads, without producing chips. (Cutting away a bushing formed by a Formdrill tool would create a weak connection.) Taps are available in metric, metric fine, BSP, UNC, UNF and NPT.

Formdrill’s tool holders and collets protect the machines from the heat generated as a result of the repetitive drilling. These accessories feature cooling disks to dissipate excess heat to protect the spindles.

Formdrill also offers lubricants, in paste or liquid form, to prolong tool life by reducing material build-up on the tool. Lubrication units are also available for use in CNC machines.

Last year the company released the new Formdrill Portable Magnetic Drill for those fabricators that require a mobile solution as opposed to working from a large drill press in a shop. The magnetic drill can be used up to M10 in 3.0 mm (7/16-UNC – 1/8NPT in 0.120” wall). “You can’t use a regular drill because it does not have the stability or the axial force needed,” Bieri said. “The mag drill can be used portably to allow the use of our application. That portability is exciting for some of our clients.”

Last year the company released the new Formdrill Portable Magnetic Drill for those fabricators that require a mobile solution as opposed to working from a large drill press in a shop. The magnetic drill can be used up to M10 in 3.0 mm (7/16-UNC – 1/8NPT in 0.120” wall). “You can’t use a regular drill because it does not have the stability or the axial force needed,” Bieri said. “The mag drill can be used portably to allow the use of our application. That portability is exciting for some of our clients.”

Formdrill-USA also manufactures special tools, based on your applications. Everything is possible: different lengths, angles, coating, cut off tips or modifications. The company’s team of engineers will assist your company in the design of these custom tools.

Formdrill helps customers find the best solution for their application with the online Application Wizard, found at www.formdrill-usa.com. The Application Wizard assists fabricators in determining steel and stainless steel applications, as well as the required tools, machining parameters and prices.

Bieri pointed out some of the major advantages and benefits of the Formdrill process, including:

- Strong connections, high pull out and torque walls.

- Cost effective process compared to weld nuts or threaded inserts.

- Repeatability and high tolerances.

- No special machines or components are required; and only a small investment is required for Formdrill’s tools and accessories.

- The process can be easily automated.

Repeatable and Airtight Savings

Bieri said the Formdrill team points out to those unfamiliar with the process how easy the application truly is. “So, it is a very specific problem that we are solving,” he said, “trying to get those threads in thin-walled material. We demonstrate how fabricators can use our drill bits in drill presses or mills — things that are found in most fabrication shops — to easily implement to our application and processes.”

Among the variety of materials well suited for Formdrill’s tools are aluminum applications. “We have seen big growth in clients that are creating new products with aluminum,” Bieri said. “We are a great alternative because they are forming an insert out of the material itself. So, you are not introducing any type of new material into the aluminum.”

Metalworking companies are also researching creative ways to cut their costs. “Not only is it a huge savings opportunity but our application is highly repeatable, and it is airtight and doesn’t leak,” Bieri said. “It is consistent versus a weld nut that might have some inconsistencies in it.”

For example, in the furniture industry, “they deal with a lot of returns due to slipping inserts, and ours don’t slip,” Bieri said. “They don’t have leakages or fail. And the cost for inserts and weld nuts is astronomical compared to pennies per threaded hole for our application.”

An example of time and cost savings resulting from the use of the Formdrill thermal drilling system is seen with a custom railing and fence building company. The company was experiencing reliability issues with the inserts they were using. The company purchased one drill bit to test the Formdrill system and was impressed by its ease of use. The customer reported he produced even better products at a more cost-effective price point. “He ended up buying a number of different full set ups for the different sizes they were using,” Bieri said.

For one fabricator, it took 10 years after seeing the Formdrill system demonstrated at a trade show before his company had a project that could benefit from implementing the thermal drilling system. The customer was impressed by the thermal drilling system and kept a sample of the product on his desk for all of those years. The customer was able to demonstrate to his boss a creative, cost-effective solution to use in the development of a new project. “He was able to demonstrate the cost benefits of using our application instead of other solutions that are out there,” Bieri said.

Based on experiences such as these, Formdrill’s team is optimistic about what is taking place in the metalworking industry, such as the increased use of aluminum in sheet metal applications. The company is also excited to assist those manufacturers reshoring their production back to the United States, and those nearshoring production within the Americas. “Our challenge is finding the people that have the problem of threading thin-walled material and letting them know we are here,” Bieri said.

With today’s skilled labor market shortages, a product that can reduce labor costs as well as create high load threads and stronger joints, won’t remain under the radar for long.

“Once they realized we are a solution to making a hole and creating a bushing in thin-walled materials that can then be threaded, it triggered a chain reaction of thoughts on where else they could use the process.” — C. Todd Bieri

“Not only is it a huge savings opportunity but our application is highly repeatable, and it is airtight and doesn’t leak. It is consistent versus a weld nut that might have some inconsistencies in it.” — C. Todd Bieri

Magical and Cost Saving Transformation

Oftentimes when the Formdrill-USA team demonstrates its thermal drilling system, at trade shows for example, attendees will comment the process looks like magic because it is transforming metal tubing by creating a bushing out of the material itself.

Formdrill’s process is commonly used for applications such as threaded connections, bearing sleeves, sealing surfaces, pivot points, brazing or soldering. Formdrill is ideal for use in automated processes because it doesn’t create chips.

- Todd Bieri, vice president of operations for Formdrill-USA, noted that the company, which is headquartered in Hasselt, Limburg, Belgium, continues to invest in grinding technology and inspection equipment to produce the best possible tools for its process, resulting in longer tool life.

These top of the line tools result in a repeatable and reliable (airtight) process that costs pennies per threaded hole. It really isn’t magic. With the Formdrill tools and your own machinery that has a strong enough torque to power the process, all it takes is for your operator to simply drill, tap and assemble.

Subscribe to learn the latest in manufacturing.