Cold Roll Mill Bearing Life Cycle Management

Combining bearing expertise with monitoring technology can solve challenges and improve productivity in cold roll steel mills.

Posted: September 27, 2023

The cold rolling mill’s purpose is to manufacture high grade sheet metal to a precise thickness, primarily for automobiles, home appliances and food packaging equipment. Figure No. 1 shows the process of cold rolling, from acid bath, descaling, and rinsing to clean the steel, through to the rolling mill stands, which can vary in numbers from one reversing single stand, to several in tandem. Regardless of the number of stands, these mills encounter the same common issues.

Despite the process being a ‘cold roll,’ the steel still generates heat as it is rolled due to internal friction. This heat has a knock-on effect to the bearings. There is a great deal of water poured on the rolls and the strip in order to keep everything cool. A side effect is that water can infiltrate the bearings and cause contamination and degradation of lubrication. In a tandem mill, all the rolls and chocks must be interchangeable. Due to the number of interchangeable rolls, the bearings need to have slip fits, which are easy to remove and replace. The problem with slip fit is that it can still move, and therefore prematurely fail. Typically, press fits on rotating component would be preferred, but a press fit bearing is very difficult to remove and replace.

The first stand in the mill has a very high load and low speed, whereas the final stand has a very high speed and low load. Therefore, the bearing design needs to be suitable for use anywhere in the mill as generally, bearings are not designated for a specific stand. Obviously, rolling cold steel and reducing the thickness requires a lot of force, so the bearings are subject to heavy loads as well. A level of precision is required too, as the steel is being reduced but also made as flat and as close to the required gauge as possible. The rolling mill bearings need to be designed to accommodate both needs.

The bearings play a critical role not only in the cold roll mill, but in many steel mill processes. Because of its value, scrapping high-grade material (through poor rolling) should be avoided. And, as always, uptime must be maintained to ensure profitability. Quality problems commonly encountered, that can result in downtime and wasted batches of product, include ‘chatter,’ and contamination of the bearings.

Roll bearing challenges and solutions

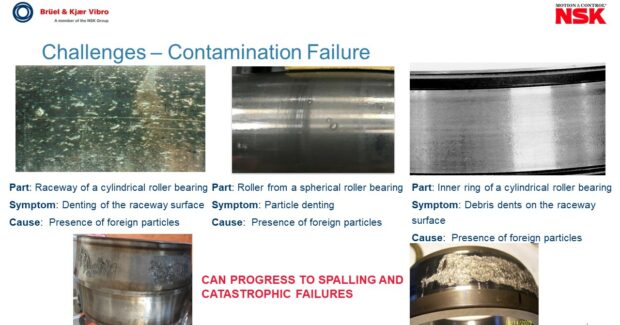

Contamination is common and can cause several issues. In stage one of the contamination failure mode, foreign debris (dust, dirt) enters the bearing, and when the rollers pass over it in the raceway, a dent or crater is formed where the material gets compressed and the steel starts to flow outward. On each side of the dent, peaks are formed, which slowly become stress risers that act like speed bumps as the rollers pass over it. With the stress concentrated in one or two small areas on each side of the dent, cracking begins due to fatigue of the material and then progresses until there is spalling. Once a piece falls out, the hardened bearing material remains within the bearing, subsequently creating more dents and accelerating the failure process. Since the bearings are not routinely opened, except during six – 12-month maintenance intervals, no one typically has a full awareness of what is happening inside of the bearing.

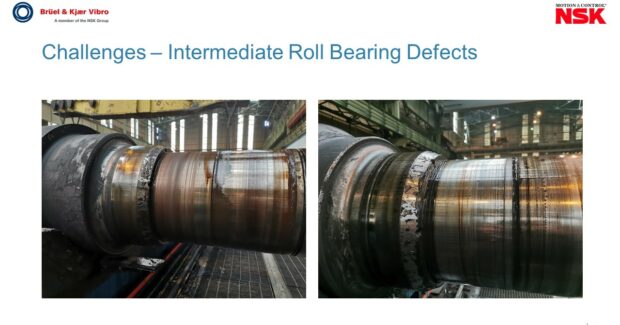

Figure No. 2 shows a bearing that was kept running until a long spall area developed (bottom right-hand side of the image). The bearing is clearly running very hot, bringing with it the risk of seizure and catastrophic damage to the bearing, the chock and the rolls. Denting always progresses, and with high loads the effect is magnified.

Figure No. 3 demonstrates what could happen with the mating components over time. If the bearing is running hot, it can start to expand and lose its fit on the shaft. Chatter can develop. If the damage is left to progress even further, eventually the bearing would get so hot it would start to weld together. Letting this damage progress can be catastrophic.

Tough steel to reduce stress

NSK developed Super Tough material and heat treatment technology for its Super-TF (STF) series bearings, which are manufactured with a non-standardized grade of steel designed specifically for contamination damage resistance, which increases bearing life (Figure No. 4). It is very difficult to achieve a clean, contaminant-free area in a steel mill, but the new material reduces the effect of contamination damage, which will extend the overall life of the bearing. The bearing demonstrates an approximately 40% improvement in seizure resistance compared to conventional bearing steel, delivering as much as 10 times the service life of conventional carburized bearings in contaminated lubrication conditions.

When a dent forms, significant aspects of the damage are the width of the dent, and how sharp the peaks are on each side of the dent. Reducing the height and sharpness of the peaks causes the stress to be less concentrated in those areas. The unique material in STF bearings, containing appropriate levels of chromium and molybdenum for increased retained austenite, helps reduce the height of the dent, the depth of the dent, and makes the peaks around the dent much more gradual and rounded off.

Optimized dispersion of finer carbide and carbonitride particles inside the material means there is less space between the particles, evenly distributing and supporting the weight better than larger sized particles in standardized carburized parts. The bearing can still accept the impact load from a rolling mill, but also features a very tough surface that is resistant to contamination damage. It also offers a higher compressive stress than through hardened bearings.

The role of machine condition monitoring: bearing lifecycle management and coil strip quality management

One of the asset challenges in a cold roll steel mill that can be addressed by CMS is roll chatter vibration, which affects both the coil strip quality and can be influenced by the condition of the bearings. To a lesser degree, this conditioning can also occur on a hot roll mill. There are two primary types of vibration chatter: third octave and fifth octave.

Types of chatter

Third octave vibration chatter

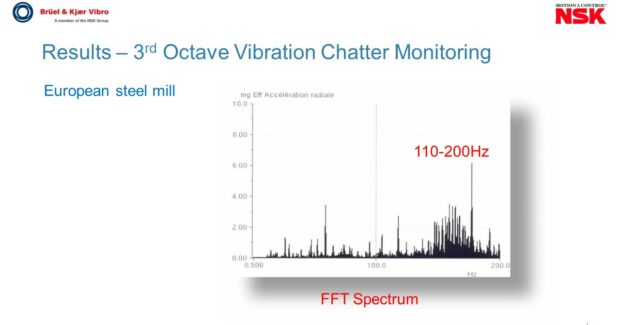

Third octave vibration chatter is caused by a self-exciting resonance, like a positive feedback loop between the strip and the structure. It is affected by the entire structure, including the steel strip metallurgy, strip tension, thickness of the strip, widths, speed, how much is being reduced, load and lubrication. This chatter occurs between 100 and 200 Hz and it is called ‘third octave’ because it corresponds to the third musical octave on a piano, which is between 131 and 247 Hz. It happens when processing a high tensile light gauge strip within, for example, a five stand tandem cold roll mill. It normally appears in the last one or two stands and can result in gauge variation and strip break. Third octave vibration is primarily affected by speed. Because this chatter escalates very quickly, there must be a fast automatic speed reduction when this condition is detected.

Fifth octave vibration chatter

Fifth octave vibration chatter is caused by an external force vibration, such as the defect bearing, roll chock liners, shaft alignment balance, hydraulic pressure system, or the motor, gears, etc. This chatter resonance will dissipate if the external vibration that excites it disappears.

More prevalent on mills than third octave vibration chatter, fifth octave vibration chatter occurs between 500 and 1000 Hz, corresponding to the fifth musical octave on the piano, and it occurs mostly in high-speed stands. The primary effect is an unacceptable surface quality issue. Normally, there is no gauge variation or strip breakage like there is with third octave, but over time, if the chatter is not corrected, it can create corrugation on the backup or intermediate rolls.

As with third octave vibration, fifth octave is speed-dependent. It can be controlled by manual or automatic speed reduction when the resonance is detected. But because it is not a self-exciting resonance, this vibration can be trended over time and observed before it appears as chatter marks on the strip.

Solutions to address chatter vibration

One solution to third octave chatter vibration is to perform a root cause analysis to identify the process parameters that excite the resonance. Once identified, these parameters can be changed. Secondly, there are systems on the market that can change the stand damping properties automatically when resonance is detected. The third solution is to install a monitoring system that can be connected to the control system for reducing speed. By monitoring the resonance vibration amplitude, speed can be increased when the vibration diminishes.

There are short term maintenance solutions that can resolve fifth octave chatter vibration until the bearings are replaced. For example, brinelled bearings can be moved to other stands and the spalled bearing can be rotated out of the load zone. The backup rolls can be switched between the stands. It is also possible to perform a root cause analysis to find the specific component that is exciting the chatter resonance, but this can be very time consuming. It is preferable to ensure all the components are healthy in the first place.

The best solution is to install a CMS to detect the chatter vibration before it affects the strip surface quality, and then reduce the speed either manually or automatically. Stand components such as the bearings, motors, and gears can all be monitored to detect potential failure modes that could excite the chatter resonance. When these defected components are replaced or repaired, the risk of creating chatter vibration is minimized.

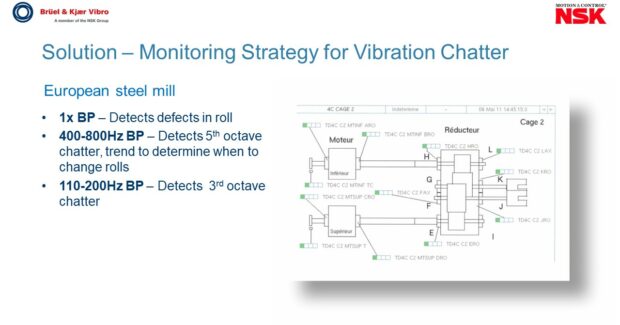

CMS monitoring strategy: extended product lifetime

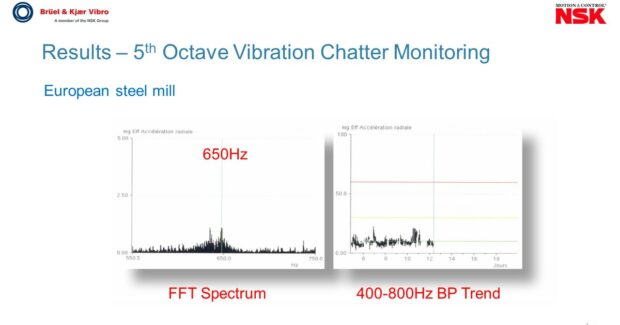

Figure No. 5 describes the CMS monitoring strategy employed by a European steel mill customer. The diagram on the right shows the work roll sensor installation for stand two on one of its cold roll mills. The bearings on these rolls are sleeve type bearings, and the monitoring strategy includes three band pass vibration measurements, one for detecting faults on the roll itself, and another for detecting the frequency range for fifth octave chatter. The third one is for third octave chatter. Fifth octave vibration measurement is shown in Figure No. 6 in a spectrum plot on the left and a trend of the band pass measurement is shown on the right and third octave vibration chatter is shown in Figure 7. Because this is only for one week’s worth of data, there is no significant chatter vibration change during this time.

For the work roll gearbox, the customer achieved 12 years lifetime instead of the original specified time of seven to eight years. Since coils with chatter marks must be scrapped, this means a cost saving of approximately $45,000 for a stainless-steel coil. Furthermore, without CMS, the mill speed is often reduced 40 to 50% for an extended time to avoid the chatter. This can be minimized with CMS because when the chatter resonance amplitude diminishes, the speed can be increased, boosting production. CMS also reduces the risk of chatter occurring because all the stand components that can excite fifth octave chatter can be monitored and corrected before the chatter occurs.

Combining bearing and CMS expertise

NSK is a full-service supplier, from design, supplying and install of the correct bearing, to supporting the overall machine health and the whole product lifecycle of a bearing. No bearing applications are identical. Load, temperature, contamination, forces, etc. can vary dramatically. A comprehensive CMS such as that provided by B&K Vibro ensures the bearings are running properly and through their desired life. This remaining useful life can be increased by detecting excessive resonance vibration in the rolls, the gearbox, and the bearings before they can lead to a premature failure. If there is an issue, it can be caught before any catastrophic damage occurs and maintenance and repairs can be properly planned.

The combined expertise also lends itself to future development that brings even more benefits to the customer. For example, data sharing between the customer and the bearing manufacturer and the monitoring system supplier. Actionable insights from the monitoring data can be used to optimize bearing design and AI machine learning can be used to further improve bearing lifecycle management.

These new tools can be used to follow the lifecycle and provide accurate, actionable insights with more lead time and reliability. Control over quality is improved, less scrap metal is produced, downtime and maintenance costs are lowered, which leads to more overall productivity.

For the past 80 years, B&K Vibro has been providing protection and condition monitoring systems (CMS) for rotating equipment globally. In 2021, B&K Vibro became part of the NSK group, which is specialized in developing new and innovative bearings and bearing solutions for customers around the globe. Today, NSK is the third largest supplier of bearings in the world, with its solutions expertise spanning a wide array of critical industries. By providing more than just bearings, NSK extends the life of bearings to help customers keep their operations moving forward with less interruption due to unnecessary failures.

B&K Vibro’s expertise has led to the development of a complete machine condition monitoring solution for rotating equipment in different industries, including metals, oil and gas, wind, pulp and paper and more. Its solutions provide early warnings and key insights into potential faults and failures across the plant for both critical assets and balance of plant machinery. By providing insights through vibration, customers can avoid catastrophic failures, maintain production, improve reliability, and reduce maintenance costs.

Subscribe to learn the latest in manufacturing.