Automation Solves Challenges and Generates Seamless Production

The value and importance of Industry 4.0 equipment and technologies results in efficiency, accuracy and happy customers.

Posted: September 29, 2023

The continued rise of automation, robotics, augmented reality and more intuitive software is the future of the metalworking industry. These advances continue to revolutionize processes, minimize waste and perhaps more importantly, assist in overcoming labor challenges.

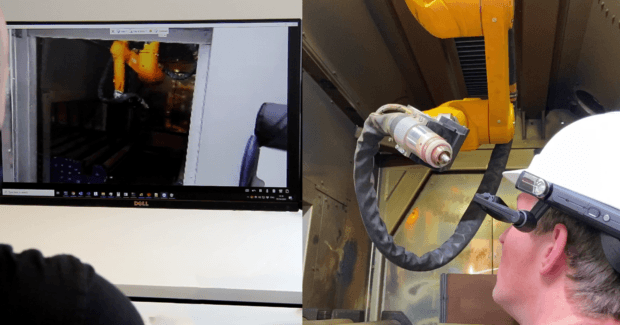

Remote Support Service Enabled by Augmented Reality

HGG Profiling Equipment BV (Houston, TX), a leading manufacturer of cutting and profiling equipment for the welding industry, offers a Remote Support Service with Augmented Reality to all global customers. Introduced during the Covid-19 pandemic, the service provides on-site assistance without the delays associated with travel and scheduling. By simply donning a custom-fitted helmet equipped with a small camera containing the TeamViewer app for visual and voice communication connectivity, 3D profiling machine operators can work with HGG engineers in real time to troubleshoot problems without incurring the time and costs to have these same engineers travel to the manufacturing site.

HGG’s engineers can read errors and viewing tab files and schematics such as a PDF document with the machine’s electrical scheme, and asking questions via a check box that asks the operator to perform a series of tasks to help diagnose a problem. Additionally, they guide operators by sharing visual pointers such as arrows and other markers that are placed in view remotely to pinpoint the correct parts and different areas of the machine. The machine’s schematics can be uploaded in PDF format and viewed in the corner of the screen. Scrolling can be done by moving your head up and down while machine inspection is performed with both hands. When viewing schematics during troubleshooting, engineers can remotely view the PDF at the same time as they are guiding the operator through the machine. The system keeps the markers in the same position even when the operator’s head turns.

The ability to visually diagnose and repair parts and systems is especially beneficial when customer and service engineer speak different languages as both parties can communicate visually via camera and remote computer. By mounting the camera on the operator’s helmet, they can perform repairs hands-free.

The IIoT Software Solution for Every Shop

AMADA AMERICA’s (Buena Park, CA) Influent software provides total shop floor control and full production visibility. By integrating everything in a manufacturing environment the barrier between the office and the shop is eliminated, thereby giving management clear, real-time visibility.

With Influent, all decision-making can be made with utmost certainty by providing current and factual data to identify inefficiencies and enable continuous improvement. Because Influent monitors and records every aspect of the shop, validating a new improvement decision is automatic. In addition, management can quickly and efficiently verify effectiveness — eliminating guesswork in improvement validation.

Influent’s Monitor provides a seamless transition to a more robust Industrial Internet of Things implementation. Influent is designed to expand with your company. From simple to enterprise-wide implementation, Influent is intended to be highly scalable.

Influent’s Enterprise is designed to integrate with the client’s existing IT investment through robust customization. Unique requirements or processes can be implemented your way with Influent’s customization.

With Influent, real-time data is automatically collected to track machine runtimes, setups, alarms and job history. Influent can connect to just about everything on the shop floor, including any brand of machine, and any ERP/MRP system. Influent empowers highly informed decision-making by connecting and collecting data from the entire organization.

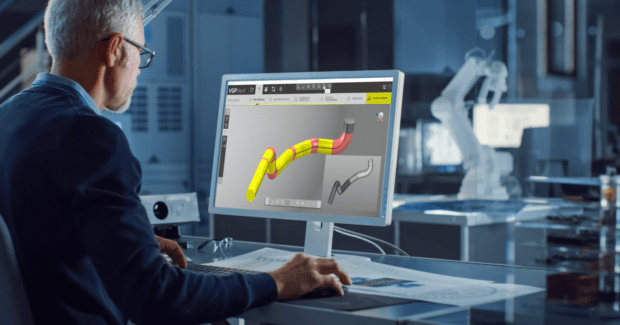

New Software Revolutionizes the World of Bending

BLM Group (Novi, MI) offers VGPNext, the new CAD/CAM programming software for its tube bending and wire bending machines that tackles the latest technological challenges. The software features a completely revolutionized graphical user interface, designed to make the operator’s job easier and machine programming more practical and simpler. VGPNext, which is part of the BLMelements software suite, improves the synergy between machine and software by simplifying core functions for more user-friendly programming. With VGPNext you can identify the part program right away, simulate the job and start production in just a few clicks.

VGPNext allows you to choose a program from the library using an archive containing images and technical data. The library collects all the programs on the server in one place, providing the convenience of preview images and numerous search filters to make this step even easier. Customized tags can be assigned to the various part programs and searches can be filtered by tag, section, material, date, machine and much more.

With the software you can import a part program, create a model from scratch, conduct 3D simulation and time estimation and more. As part of the BLMelements software suite of native software programs, VPGNext makes the most of the power of BLM GROUP’s equipment. Programs include ArTube, ArtCut, PartViewer and ProTube.

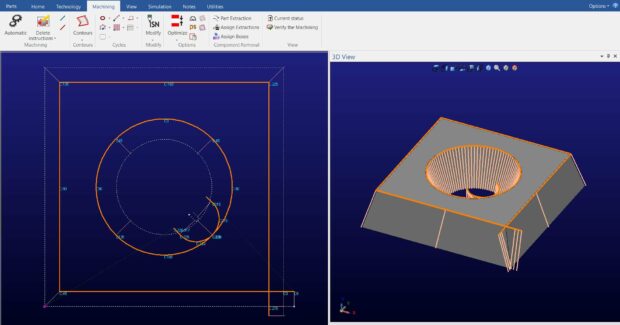

Software Features More Than 80 new Updates

Lantek Sheetmetal Solutions USA (Mason, OH), a multinational pioneer in the digital transformation of the sheet metal, metal cutting and processing industry, has incorporated more than 80 new improvements and advances in Lantek Global Release 2022. The update features significant improvements in flexibility, enabling the software to be adapted to individual production needs; usability, for a better user experience and process visibility; and efficiency and automation, reducing manual steps for faster processing.

The Lantek Expert CAD/CAM nesting software solution has been improved to allow access from different areas of the system. A redesigned module allows automatic tagging technology to be applied, providing improved configuration options to adapt to any part geometry or cutting quality, avoiding the possibility of imperfections in the part. The new version also facilitates the native interpretation of bending line technology from the import stage, as well as the automatic import of nests created by external systems including the automatic detection of repeated parts.

Lantek Flex3d has been updated to work seamlessly with new machines, devices and technologies used to cut structural tubes and profiles. The new machine configuration module has been completely redesigned for faster system start-up on any type of machine. The new advanced milling technology management supports different tooling and cutting strategies for machines that incorporate this technology, expanding machining possibilities available.

Lantek MES and Lantek Integra handle workshop management by accurately tracking resource loading, orders, delivery dates, quality and stock levels. Its ability to maintain traceability and flexibility to react to changing circumstances is possible by improved capabilities in recording data related to downtime and reasons for part scrap during production. What’s more, in the new version, multiple improvements have been made to the Power Sync integration engine, to export production information from the MES to external systems for any type of operation.

Portfolio of Solutions Now Available to Fabrication and AM Sectors

Siemens (Chicago, IL) now offers its full portfolio of machine control hardware, software and cloud-based services to the fabrication industry. The special highlight of this is the new Sinumerik Motion Control (MC) system — an open, industrial PC-based controller with embedded CNC and PLC in a Windows® 10 environment. Also included are end-to-end solutions for additive manufacturing and digitalization, its high-level flagship Sinumerik 840D sl CNC for robotic application, plus the Manage MyMachines application running on Mindsphere, the Siemens cloud for industry.

Manage MyMachines can remotely connect to machine builders and end users as well as Siemens Technical Application Centers located around the globe to show machine status, operating mode and program status in real time. Machine builders and end users are able to accurately monitor machine performance for their globally installed base or factory production network located around the world. This provides a clear picture for the assessment of machine performance, predictive maintenance and OEE.

The latest developments in the Sinumerik 840D sl CNC and its Virtual NC Kernel (VNCK) are included, as well. With Sinumerik Run MyVNCK, machine users can create their own control-specific virtual world by embedding the original CNC kernel into a virtual machine. This allows users to seamlessly plan, verify and optimize their production steps in a virtual environment, while avoiding possible programming errors and collisions. This technology can be applied towards OEM applications in laser cutting, waterjet, deburring, bending and more.

Siemens also offers its end-to-end solutions for additive manufacturing. Working together with several machine builders, Siemens is already involved in the motion control of this emerging manufacturing segment.

New Software Boosts Productivity in Connected Manufacturing

High-tech company TRUMPF’s (Farmington, CT) Oseon software can help create significantly leaner production processes and make major gains in productivity. The software includes a range of new options for managing the transportation of materials in a flexible and automated fashion.

Oseon is a great choice for any sheet metal fabricator looking to boost the competitiveness of their production activities. The software can be used on shop floors where digital connectivity is still in its infancy as well as in fully-fledged smart factories, and it delivers real benefits whatever the size of the company. Oseon also makes life easier for production workers. Using a tablet, they can see all the relevant information on a job without leaving their work environment.

“Production often comes to a halt because the workers don’t have the information they need on the current job,” said Claudio Santopietro, software solutions sales manager. “In normal circumstances, it’s a hassle to search for the relevant routing slip or look up the details in the production scheduling program. But with Oseon, all the data they need is immediately and clearly visible on the screen. That prevents mistakes being made and saves time.”

Thanks to its open interfaces, the software is also suitable for users who want to integrate machines from other suppliers into their fully networked production in addition to TRUMPF machines.

Software Offers Machine Preventative Maintenance Tracking

Wintriss Controls Group (Acton, MA) offers new, advanced features in its ShopFloorConnect® OEE and Data Collection Software. It gives fabricating and metalworking professionals efficient and easy-to-use software for increased efficiency and reduced downtime, including when remote monitoring is required. The software can significantly increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks. The new PM Tracker enables users to track important machine preventative maintenance items by run hours or machine cycles, issues targeted alerts when an item requires PM, and tracks the maintenance work history for all machines.

Additionally, the new Universal Interactive Application Program Interface enables users to quickly set up two-way data sharing with any ERP or MES software.

Subscribe to learn the latest in manufacturing.