T.J. Snow: One-Spot-Shop for Resistance Welding

As the company celebrates its 60th year in business, it is excited about the future of its products and its place in serving the metalworking industry.

Posted: August 22, 2023

From its beginnings in founder Jim Snow’s dining room in Chattanooga, Tenn., T.J. Snow, Co. is celebrating its 60th anniversary this year as a full-service leader in the resistance welding industry. The family-owned company offers resistance welding machinery, parts and supplies. The company also remanufacturers other brands of resistance welders and carries an extensive inventory of used resistance welders.

“Resistance welding is a neat process, it is fast, and it is strong,” said Sam Snow, CEO, T.J. Snow. “You are not adding anything, you are not taking anything away. You are using the metal that is already there and making a weld that is stronger than the original material.”

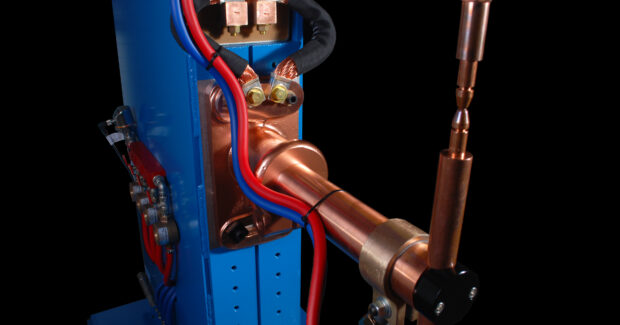

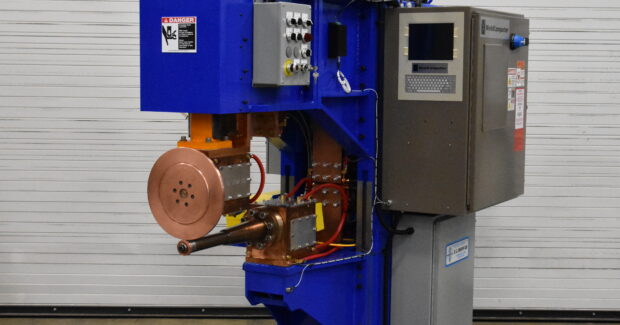

T.J. Snow’s core product is resistance welding machinery, and that spans the gamut from a shop that has one small machine in its operation, all the way to a Tier I automotive supplier that is putting machines into a line, as well as some with small robotic workcells, noted Sam Snow.

“We are not a line builder; our niche is the resistance welding side of things,” Sam Snow said. “We do a lot of dedicated automation. We are building a machine that is designed or at least tooled specifically for a part or for a family of parts, and that is what it is designed to do efficiently and economically.”

“The operator is there to load and unload the parts,” said Tom Snow, chairman, T.J. Snow. “And that really leads into one of the changes that we continue to see,” Sam Snow added. He pointed out that customers continue to state they have a hard time finding operators. So, Sam and the team go through a process with customers to determine the machine size they need, the amps they need, and the force needed to make welds. The company analyzes how much automation a customer needs; and how much automation they can justify.

“So, you have varying levels, from a totally automated conveyor feeding the raw material parts into a machine and taking them away,” Sam Snow said, “to a total manual process where the operator is positioning the part by hand in the correct spot to make all the welds. We work with customers to figure out what fits in their budgets, and what they want.”

T.J. Snow’s in-house design team designs and builds its resistance welding machinery in Chattanooga. “Our process is usually where a customer brings parts in, and we do a runoff on our floor to make sure everything is good,” Sam Snow said. “Oftentimes the machine ships out to the customer, and oftentimes our service department follows the machine out and provides on the floor training and helps start the machine out in the field.”

T.J. Snow’s expansion and growth over the years is tied to the automotive industry’s OEMs continuing to establish and expand manufacturing plants in the southeast United States, which attracts all tiers of suppliers. While the company does have automotive OEM customers, the majority of customers are Tier I and II suppliers to the automotive industry: those that sell mufflers, shock absorbers, catalytic converters, stampings and other products that require resistance welding. The next evolution of serving automotive suppliers will involve supporting electric vehicle battery manufacturers.

T.J. Snow offers various types of resistance welders such as spot, projection, butt, flash, seam and more. The company also offers custom designed complex Multi-gun Welders and Turnkey Robotic Systems.

The company also remanufactures any brand of resistance welders, either it is a customer’s existing machine or one selected from T.J. Snow’s inventory of used welders.

Sam Snow said that the company’s business model is to surround itself with the components that comprise the world of resistance welding. In addition to machinery, the company is a large distributor in the United States of resistance welding supplies such as copper tips and other wear items. “We keep a large stock and ship quickly,” Sam Snow said.

He added another way that the company surrounds itself within the world of resistance welding is through its dedicated service staff, which provides resistance welding training to operators throughout the country. Resistance welding is a niche area of the welding world and while most welding engineers have some form of resistance welding training, they most likely have more MIG welding training, inspection and so forth. “We bring a lot of that expertise to people to help set up new parts and develop processes and set customers up to run their machines with success,” Sam Snow noted. “And, if they have a machine that breaks down, we have service guys who travel out in the field and fix our machines and many other manufacturers’ resistance welders as well.”

“That is where the company airplane often plays a role,” said Tom Snow. “We have used a small airplane for decades to provide service to customers.” T.J. Snow has service and training technicians who are also pilots and can fly to smaller airports to be closer to customers, instead of flying into larger airports and then having to drive for hours to reach customers. Instead of dealing with the hassles of flight schedules and traveling with tools on commercial airlines, with the company airplane, the technicians have the flexibility to reach customers and fix their machines and return home sooner. “It is unique and provides a lot of flexibility for us,” Sam Snow said.

Training For Now and in the Future

For the past couple of years, the T.J. Snow team has expanded its services to provide more resistance welding training programming, Tom Snow said. “Resistance welding is a neat process, but it does take a little skill and knowledge to set it up correctly,” Sam Snow said. “That is where we see customers struggle the most. They have worked themselves into a corner where the weld process isn’t stable. Or they are trying to do things that the machine isn’t capable of doing. Our goal is to help our customers be successful. We help them become their own in-house resistance welding experts.”

T.J. Snow provides training in specific applications. The company also conducts regional training classes for all levels of resistance welding, covering fundamentals in an interactive and fun way.

“We host up to eight training classes in different cities each year; usually in the eastern half of the U.S.,” said Patton Locke, marketing director, T.J. Snow. The company also offers convenient, live online training classes. “We have also developed an on-demand Operator E-course for operators who have no training to introduce them to resistance welding,” Locke said. “We launched earlier this year.”

In addition to training future resistance welding professionals, T.J. Snow is adapting to changes in the metalworking sector, particularly when it comes to the use of more high-strength steels used to build cars such as welding with aluminum that has become more prevalent in vehicles.

“High-strength steels are trickier to resistance weld,” Sam Snow said. The company has developed an expertise and offers two options: one is a standard resistance welder; the other is called a capacitor discharge, or CD resistance welder. “With a lot of those applications you are welding a nut onto that stamping,” Sam Snow said. “We are proud that we built the welders that weld the nuts on many of the parts for the Ford Bronco.”

T.J. Snow also develops robot cells when it makes sense. As an example, the company welds automotive seat frames for the back seats of cars. Sam Snow said the frame looks like a rectangular skeleton with a bunch of wires. “So, to do that same part you put it in a fixture and have a robot come in and do each of the welds all the way around,” he said. Alternatively, you can load the part and have a dedicated welder basically do all of the welds at the same time through cascade fire, doing 30 or so welds on the part in a few seconds, rather than having to reposition the robot.

“You can do that part either way, and you can get the quality either way,” Sam Snow said. “That is a challenge for us; to work with the customer to find the right solution on how to approach each of these problems. The labor part becomes more of an issue for companies because they want to ensure the operator, who is usually not skilled, is able to work safely and also produce goods parts without having a lot of skill.”

The Best Solution for the Job

T.J. Snow collaborates with its customers to solve their challenges. For one customer transitioning from manually welding a metal wire part to doing the process in a robotic welder, the company had to determine the best way to position the part to weld each of the cross wires in the correct spot. There were 20 welds on a part and each weld took at least five seconds to reposition and weld again.

With the robotic welder, the customer is able to load those parts in and out of the fixture offline, and feed the fixture to where the robot is doing all the positioning and all the welds.

“In this case, it was both a safety factor to where now you have the operator away from the movement and away from bench point potential; and also, an efficiency factor,” Sam Snow said. “Before you were counting on the operator’s skill to position the part correctly in the welder to where those two wires were crossing over and doing the weld. Now, you have taken that question mark of positioning out with the robot.”

For customer Knapheide Manufacturing Co., Quincy, Ill., the company has been able to incorporate resistance welding into their products in ways that they haven’t done before, noted Lane Sparrow, company spokesperson. He is seen in the T.J. Snow 60th anniversary video, posted at the company’s website. Sparrow said that with T.J. Snow his company is not just buying a machine but also a service. “You are buying the expertise of their staff,” he said. “They are always on call. Firsthand, they are the best people to work with.”

The training on the resistance welders is also important to Knapheide, which has staff members who are designated as trainers for new hires and current staff regarding the processes in a day-to-day shop environment. “So, these trainers need training themselves and T.J. Snow over the years has been great at providing us with those trainings,” Sparrow said. “Working with us, working with our operators, helping us develop training for in-house that we utilize ourselves.”

For Schaefer’s Electrical Enclosures, Scott City, Mo., T.J. Snow has provided several new and remanufactured resistance welders, as well as training. “Their team has done a really good job in working with us to figure out what is the right machine for our application,” said Steve Lentz, process engineer for Schaefer’s Electrical Enclosures, in the anniversary video. “And if there are any type of modifications or things we would like to see differently, they work well with us on getting those set up just to meet our needs.”

Lentz said T.J. Snow’s training and instruction has been excellent and good for his company’s employees. “The instructor was knowledgeable and even taught our seasoned welders a lot of new things that they didn’t know about resistance welding,” Lentz said. “The service department is knowledgeable and promptly gets to you and makes sure they can get you up and running again.”

That quick to assist service factor was key for Spartanburg Steel Products, Spartanburg, S.C., when the company had a hanging gun go down. After a call from Spartanburg Steel Products, T.J. Snow prepared the products needed to assist in returning the hanging gun back to operation. Kollin Simpson of Spartanburg Steel Products drove to Chattanooga to pick up the part, drove back and installed the part with the T.J. Snow service department walking him through the installation during a phone call. “We were back up and running production within 24 hours of it going down,” Simpson said. “We choose T.J. Snow for their product and services due to their extensive knowledge when it comes to resistance welding.”

Simpson added that T.J. Snow’s representatives will pick up the phone no matter what time of the day it is. “Whether it is something minute or extremely in depth,” Simpson said. “It has led to a lot less downtime and a lot more production value then what we could do without them.”

Sam Snow shared these thoughts regarding customers: “A company’s investment needs to make sense. They are not spending money just because — they are trying to solve problems. If you can solve a problem, then you can justify spending the money.”

T.J. Snow forecasts a bright future. For example, the automotive industry is going through several changes, including releasing new models versus just maintaining a process. “We see the economy as being healthy and manufacturing being healthy,” Sam Snow said. “And we are glad to be partners in helping people be successful.”

www.tjsnow.com

Background as a Supplier Leads to the Creation of Water Chiller Business

T.J. Snow, Co. has long stocked resistance welding supplies at its Chattanooga, Tenn., facility for the resistance welding industry, which includes water chillers. Most resistance welders are water cooled so it made sense for T.J. Snow to provide a one-stop shop for customers; through T.J. Snow, customers could purchase a water chiller based on their needs and specifications. Customers, and others, learned that the company stocked water chillers, which led to people outside the resistance welding industry asking to buy water chillers.

Two years ago, T.J. Snow began importing and private labeling water chillers, stocking large quantities in Chattanooga. There are more than 400 water chillers in stock. The new division is called Industrial Water Chiller and its two brands are: IPC (industrial process cooling), and Nordic. There is a separate website for the water chiller business, www.industrialwaterchiller.com.

The division has two outside salespeople who are only quoting water chillers for industries outside of welding, said Sam Snow, CEO, T.J. Snow. “We have two HVAC service technicians who are doing technical support.”

Right off the bat, T.J. Snow was one of the largest customers of the new division. In addition to welding customers, customers looking for process cooling include laser manufacturers, machine tool manufacturers and others. Non-industrial applications include MRI machines, concrete plants that need to regulate the water temperature in their mixes, marijuana processors; and even a chocolate factory that works with a water-cooled table to make their products.