Nesting Software Enables the Reduction of Waste and High Costs

MES systems specifically designed for sheet metal operations use data to help maximize your shop’s sheet metal supply.

Posted: August 15, 2023

In the past few years metal processing shops have had to adapt to many ebbs and flows regarding production orders, staffing shortages and the rising costs of materials. In fact, the World Bank Metals & Mineral Price Index rose 10% in the first quarter of 2023 due to material shortages and the resulting cost hikes, especially in sheet metal, stainless steel and nickel. And, while the index is forecasted to fall as the supply chain recovers, shops should still work to adopt practices to do more with less. In this ever-changing manufacturing landscape, the ability to adapt consistently will go a long way to determining a shop’s success. If you haven’t invested in a Management Enterprise Systems (MES) system designed for sheet metal operations, now might be the time.

Management Enterprise Systems for Sheet Metal

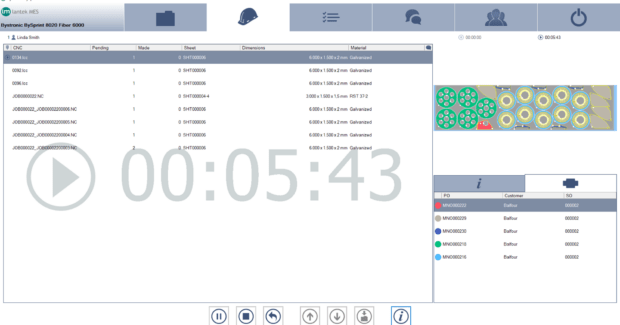

MES systems have been around for years, and some can be customized or adapted to sheet metal cutting applications. However, the level of detail within these systems is lacking and the ability to accurately plan is limited. The Lantek MES has been designed to simplify grouping parts using parameters such as material type and thickness, machine type, sales order, customer and delivery date. Parts from different projects can be mixed for reduced inventory. Maximizing sheet metal real estate is optimally done by using a nesting program.

MES systems have been around for years, and some can be customized or adapted to sheet metal cutting applications. However, the level of detail within these systems is lacking and the ability to accurately plan is limited. The Lantek MES has been designed to simplify grouping parts using parameters such as material type and thickness, machine type, sales order, customer and delivery date. Parts from different projects can be mixed for reduced inventory. Maximizing sheet metal real estate is optimally done by using a nesting program.

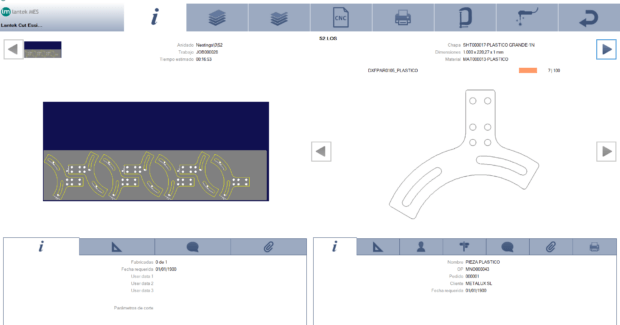

Nesting algorithms for sheet metal essentially map out part arrangements on metal sheets. Parts can be of different shapes and sizes, allowing multiple jobs to be run at once using the same metal sheets. When a sheet format is changed, the new information can be loaded into the system for accurate traceability and to keep everyone on the same page. Because all pertinent information is already loaded into the system, design and manufacturing codes are checked for errors prior to cutting. The Lantek Expert 2D CAD/CAM nesting system, for example, includes a Parametric Parts Library, open database for information management, and a floating license option so that multiple users can access the system. This is especially important for multi-site operations where a job can start in one part of the world and end in another.

In the world of 3D, part geometries become a little more complicated making simulation all the more important. Imagine playing the guessing game with a large, hard-to-obtain piece of sheet metal and a bevy of tricky part shapes and dimensions peppered throughout its surface. One small mistake can result in the entire sheet needing to be scrapped, possibly affecting several jobs at once. By viewing the parts, part layout and cutting process ahead of time, errors are reduced, edits can be made where necessary, and new designs created from 2D outlines. The flexibility to create nests automatically or manually gives the operator even more control over the operation.

In the world of 3D, part geometries become a little more complicated making simulation all the more important. Imagine playing the guessing game with a large, hard-to-obtain piece of sheet metal and a bevy of tricky part shapes and dimensions peppered throughout its surface. One small mistake can result in the entire sheet needing to be scrapped, possibly affecting several jobs at once. By viewing the parts, part layout and cutting process ahead of time, errors are reduced, edits can be made where necessary, and new designs created from 2D outlines. The flexibility to create nests automatically or manually gives the operator even more control over the operation.

Managing the Process and Banking Information

Lantek’s system features a power sync integration engine that allows the operator to export production information from an MES to external systems for virtually any type of operation, including cutting processes. Further, because of these integration capabilities, the MES can be used as a bridge between any third-party ERP and our CAD/CAM environment. Again, keeping things consistent among multi-sites no matter where in the world they are located. All of these features work well separately, but it’s the MES system that ties them all together to determine the best way to maximize a shop’s resources.

The MES directs the execution of all manufacturing operations in the workshop, from launching work orders to plant production processes to finishing the end product.

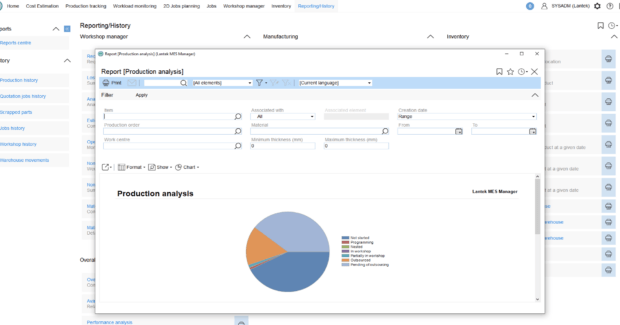

An MES should have the ability to manage the entire production process, from order input to part inventories to available materials — and material type — to scrap for each operation. An MES designed especially for sheet metal operations has algorithms built into it to be able to allocate material for each project and track material price changes. Lantek’s MES keeps track of material remnants from previous jobs for reuse. The expert function can determine when a collision might occur but adding micro joints and altering lead-ins to ensure parts are not scrapped during manufacture.

Analyzing it All

The information, or data collected by the MES is crucial to the successful operation of the shop and its efforts to keep scrap low and make the most out of its resources. By analyzing data from each production process, information managers can find the real OEE performance for every machine, final parts when compared with the tons of materials processed and other important factors. Additionally, they can visualize the resources used in the past — what worked, what didn’t, anticipate stock outs, and determine how much stock will be needed for future jobs. When the entire software system is fully integrated, all data is up-to-date and at hand to make the best decisions regarding material usage over time.

Experience Helps

There are quite a few MES software products on the market today, but their functionality is built for general job shop management. Material waste is a very real thing that needs to be managed using programs that are designed to capture all pertinent data to automatically filter it into buckets or categories that allow operators to get a clear view of their operations in real time. Not all software developers have this expertise.

In an ever-changing manufacturing landscape where lean manufacturing principles make even more sense than they ever have, the ability to have a firm grasp on your operations as they pertain to waste and high costs is paramount. You might not be able to control the price of sheet metal but you sure can control how much of it you use.

Subscribe to learn the latest in manufacturing.