Connecting the Dots: Shop Connectivity and Automation

The key to success for shop connectivity and automation is a gradual, steady (and continuous) pace.

Posted: August 18, 2023

Since CNC machines began to hit the market more than 50 years ago, the manufacturing industry has been in a constant state of technological flux. And while some changes — from automation to AI — may seem swift and drastic, the seeds of innovation are sown well before widespread adoption.

Similarly, change within a single machine shop or manufacturing plant rarely happens overnight. Most best-in-class facilities have gotten to where they are today through a series of gradual steps toward digitization and automation.

The Machining Technology Adoption Lifecycle

The first move toward digitization in manufacturing changed metalworking as we know it. CNC machines were developed at MIT in 1952 as a way to enable more complex part production that, at the time, wasn’t possible with manual milling.

Like most novel technologies, it wasn’t until several years later (the early 1970s) that CNC machines began to hit manufacturing floors — thanks to faster, more accessible computing technology. The CNC revolution really hit its stride as CAD/CAM technologies (first invented in the 1950s) became more popular in the 1980s and 1990s. Finally, internet connectivity became more common in the ’90s and early aughts; but the Industrial Internet of Things (IIoT) has only truly picked up speed in the last decade.

A Roadmap for the Future

Since digital technologies began to infiltrate the industry, machine tool, automation and tooling manufacturers have been asking, “What’s next?” To that end, new product development usually starts with a future state in mind. A connected digital boring head, for example, might seem like a nice-to-have tool; but for those progressing toward the ultimate goal of fully lights-out manufacturing, it’s a small but vital piece of a much bigger puzzle.

What are all of the hundreds (maybe thousands!) of elements the industry will need to reach an automated manufacturing utopia? How can these elements integrate more seamlessly?

While machining equipment and accessory manufacturers are hard at work to answer these questions, large manufacturers and small job shops alike are asking how they can put what’s available now to good use. It can be a delicate and intimidating endeavor — implementing the right technologies at the right time to maximize productivity and ROI. Fortunately, there are some proven strategies to help get there.

The Essentials

The idea of a “Connected Machine Shop” can sound daunting: Some unattainable state in which every machine and accessory communicates seamlessly and robots flit around in perfect sync with their human counterparts. In reality, there is a wide spectrum of success; and it’s all about finding what works for your needs now and how to build toward the future.

Small Steps (Not Huge Leaps)

Overly ambitious, sudden transitions are, at best, painful; at worst, they could fail outright. Today’s connected, automated and AI-enabled technologies come with a learning curve, and it’s not just operator training. Organizations and their employees need time to adapt to the new procedures, protocols and approaches that come with connectivity and automation.

Even for those who already have their feet wet, implementing new technology starts with identifying an area for improvement and choosing the right solution to optimize. For example, a shop having issues with scrapped parts might look for ways that automation and connectivity can reduce human error, save time and improve accuracy.

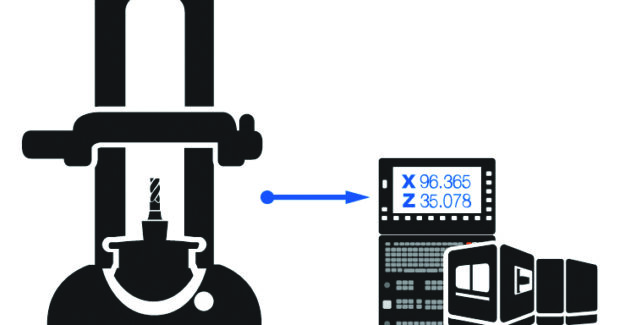

Today’s connected presetters, for instance, send tool data directly to the machine. This not only allows for productivity improvements (offline tool setup to keep those spindles spinning); but also eliminates the need for operators to manually input data at the machine (risking errors). Best of all, it makes the job easier on the operator.

Digital boring heads are another example of a small but impactful step toward more automated operations. These helpful tools display setup measurements on a small readout on the head, making precision adjustments faster, easier and more fool-proof. The next generation of these products takes things further with machine connectivity, enabling closed-loop boring operations without human intervention. Boring heads integrate directly with the machine tool control via app or technology cycle, automatically adjusting themselves without any human intervention.

Shops that enact a regular cadence of these minor improvements will look back five years from now and be impressed with how far they’ve come.

A Culture of Continuous Improvement

A journey of a thousand miles begins with a single step. But contrary to popular belief, the hardest part isn’t making the first move — but rather marching on in the face of the challenges, training demands and operational transitions brought on by new tech implementations.

When it comes to next steps, it’s not always about adding new connected or automated equipment to the arsenal. Organizations must first maximize the features of the technologies they have.

Think of an automated/connected machine, tool or accessory like the human brain — most people only use a small fraction of its power. The reasons are myriad. Sometimes it’s about incompatible equipment; sometimes it’s a lack of training, time or resources to implement; sometimes users might not even know certain features exist.

Take, for example, a recent survey of our digital boring head customers. The large majority — 65% — say they do not use the Bluetooth connectivity feature that allows them to connect the head to a mobile device (via an app) to unlock the full features and benefits.

This is just a small window into the issue. Larger machining and automation cells — and the accompanying software applications — have hundreds of powerful features that take time and effort to set up, learn and integrate. Manufacturers who commit to building on and maximizing the use of these technologies over time will be more successful.

Better Integration, Fewer Silos

By now, manufacturing facilities of all sizes are making use of automation, connectivity and AI in some way. But even for those who are hitting their stride, integrations are often limited to individual manufacturing cells. This has an impact on physical production and business strategy.

Take, for instance, a lights-out manufacturing application that produces 50 parts overnight without any human intervention; but operators return in the morning only to spend hours manually deburring.

Another example pertains to the rich data and insights that come from connected machines, tools and accessories. Some manufacturers achieve consolidated reports to get a clear picture of cell-by-cell productivity. But what about overarching insights and averages across all operations, combined? And how are manufacturers slicing and dicing that data to help make better business decisions — from more accurate estimates on new jobs to achieving just-in-time tooling inventory?

Part of the onus is on equipment and tooling manufacturers to work together toward more plug-and-play offerings — and that’s in the works (with off-the-shelf automation integrations, tooling and machine partnerships, etc.). But manufacturers can take steps toward this, too, via the continued improvement strategy previously mentioned.

Plant or operations managers should dedicate time each day or week to explore ways to build deeper, more impactful connections between existing equipment and technologies — or to find new applications that break down the silos between them.

Anticipating Market Trends

To choose the right technology now, manufacturers need to look to the future. It might seem like a no-brainer; but all too often, organizations get swept up in the buzz around the latest technology, without thinking critically about how it plays into their long-term strategy.

The skilled labor crunch is one example. As machinists retire, manufacturers may be tempted to implement technologies that make machining operations less complex and reduce the risk of human error; however, there’s another element to consider: young people are seeking jobs that give them the opportunity to work with cutting-edge technology and automation. Shops must integrate that tech if they hope to attract and retain the next generation of operators.

Another obvious example is the increasing demand for speed, cost efficiency and part complexity. Depending on the industry in which they work, some manufacturers may be feeling the pressure more than others. The consumer electronics, automotive and aerospace industries, for example, have all been on a path toward smaller, lighter and/or more complex part geometries for years — with no end in sight.

Before implementing, consider the factors that could impact your specific operations and industry in the next three-to-five years.

Go Forth and Prosper

Connecting and automating manufacturing operations can be complex. But manufacturers should know there’s plenty of support. Machine, tooling, robotics and accessories partners — along with integrators and consultants — are ready with valuable knowledge to help.

Beyond that, local, state and federal governments have millions (maybe billions) of dollars available in the form of grants and loans. It’s there for the taking for manufacturers who are committed to automation and operational improvement.

And regardless of the investments you choose to make, remember one thing: when it comes to manufacturing connectivity and automation, there is no ultimate destination. It’s all about continued momentum — and learning as you go.

Subscribe to learn the latest in manufacturing.