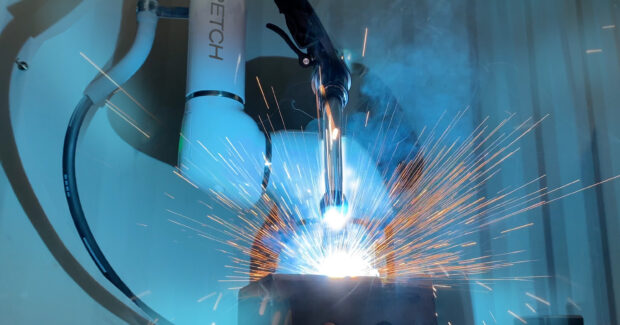

FABTECH 2023: Teach-By-Touch 7-Axis Cobots Take Over Repetitive Tasks

Productive Robotics’ Teach-By-Touch 7-axis cobots automate tasks from welding to milling and grinding, which boosts production efficiencies and reduces operating costs.

Posted: July 25, 2023

Reshoring, part diversification and the need to bridge the skills gap have prompted fabricators and job shops to look for ways to boost production efficiencies while reducing day-to-day operating costs. Productive Robotics’ 7-axis, augmented intelligent OB7 collaborative robots improve quality and speed up production rates by automating welding tasks and repetitive processing activities. The OEM will demonstrate its Blaze stand-alone, single station and two-station welding systems as well as CNC milling, deburring, grinding and gluing at Booth #B13018. Visitors will also be able to test Productive Robotics’ proprietary, “no programming” user interface by teaching OB7 a job in just seconds. Booth models include OB7, OB7-Stretch, OB7-Max 8 and OB7-Max 12.

“We believe cobot programming is only easy for programmers so we eliminated it entirely,” says Zac Bogart, president of Productive Robotics. “This allows us to remove barriers like complex integration, high costs and programming and put budget-friendly advanced robotic automation into the hands of small job shops and large manufacturers. We’ve engineered our cobots to perform a diverse number of pick and place activities and highly repetitive jobs for industries that range from medical device and food and beverage to miscellaneous metals and machinery.”

To automate OB7, fabricators can add a Productive Robotics parallel electric gripper/end effector, patented robot rolling stand and work table. The cobot is also compatible with other grippers, cameras and

accessories. Data collection is supported by Productive Robotics’ cloud analytics system making it easy

for small to medium-sized job shops to implement real-time reporting on cobot activity. Installation of the OB7 can take approximately two hours.

Productive Robotics launched its stand-alone Blaze Welding Cobot in 2023. It can be used with a customer’s existing table, fixtures and welder at half the cost of other systems on the market. Unlike 6-axis robots, the 7-axis Blaze Welding Cobot can maneuver around all sides of a large or complex parts and fixtures, allowing it to perform more weldments in a single setup. Run by the OEM’s augmented intelligent teach-by-touch OB7 Stretch cobot, Blaze can accommodate high or low mix volumes, short or long part runs.

In 2022, Productive Robotics introduced its Blaze Duo and Blaze LF automated welding systems. Blaze Duo’s automated doors separate two identical weld stations, minimizing downtime by allowing operators to safely set up one job while the cobot is welding another part. Direct video monitoring, an unlimited library of welding recipes and a “no programming” drag and drop tablet controller allow the cobot to learn any job in minutes, from simple to complex paths. Blaze LF provides fabricators with the capability to automate processing of both large and small size weldments. The model’s 8-ft.-long table gives manufacturers unrestricted access on all sides as well as easy loading and unloading of components. Blaze Duo and Blaze LF are run by augmented intelligent teach-by-touch OB7 Stretch cobot.

Subscribe to learn the latest in manufacturing.