FABTECH 2023 – 3D/Additive Manufacturing, Forming & Fabricating

Hall A: 3D/Additive Manufacturing, Forming & Fabricating of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.

Posted: July 23, 2023

3D/Additive Manufacturing, Forming & Fabricating (Hall A)

Fabricating & Metalworking is proud to present the FABTECH 2023 Product Showcase, which is an invaluable guide to navigating the trade show floor at McCormick Place in Chicago this September. This FABTECH section outlines some of the products and demonstrations expected to be on display by more than 1,500 world-class suppliers in three exhibition halls. An estimated 45,000 people will attend FABTECH 2023.

Pavilions at FABTECH are dedicated to 3D/Additive Manufacturing, Forming & Fabricating (Hall A); Welding, Welding Automation, Robotics & Industrial Automation (Hall B); and METALFORM, Finishing, Tube & Pipe (Hall D). This article is dedicated to: Hall A– 3D/Additive Manufacturing, Forming & Fabricating

AMADA to Debut Robotic Bending Systems, Display Variety of Machinery

AMADA AMERICA, INC. (Buena Park, CA) will introduce the new EGB 1303 ARse bending robot at Booth A1304. This high-speed, electric press brake is combined with an Automatic Tool Changer (ATC) for precise processing of high-mix, low-volume parts. This advanced machine is equipped with a three finger backgauge that eliminates gauging mistakes and the need for part locating fixtures to streamline the production process. Additionally, the robot’s NC Cooperation guidance function features a mobile display, voice operation, and provides notifications to enable efficient operation. To further boost productivity, Bi-S II Bend Indicator Sensors automatically measure and correct bend angles up to 85% faster than Bi-S technology. And a new electric Auto-Crowning system maintains longitudinal accuracy throughout production.

AMADA AMERICA will also introduce the new EGB 6013 ARe bending robot. This high-speed, electric press brake delivers precise processing of high-mix, low-volume parts as well. To support 24/7 operation, this machine is equipped with new removable part trays, both vertical and horizontal, to enhance productivity and organization. Similar to the EGB 1303 ARse, the machine also features a three finger backgauge; an NC Cooperation guidance function features a mobile display, voice operation, and provides notifications; and the Bi-S II Bend Indicator Sensors automatically measure and correct bend angles up to 85% faster than Bi-S technology. The new electric Auto-Crowning system maintains longitudinal accuracy throughout production.

Among the other machines AMADA AMERICA will display include the latest generation of servo-controlled press brakes, the EGB 6020 ATCe, which is equipped with a high-performance electric drive system combined with an ATC and voice command control. These production-enhancing features ensure high-speed bending and repeatable accuracy even if an operator lacks experience. In addition, a compact, newly-redesigned ATC can precisely load complex tool layouts within minutes — making it the ideal solution for variable lot sizes and the seamless introduction of rush jobs.

AMADA AMERICA will also display the REGIUS 3015 AJ (12 kW) with an Automation & Parts Sorter, which combines the world’s fastest 3-axis linear drive system and a variety of autonomous features with 24/7 processing capabilities. The VENTIS 3015 AJ (6 kW) Fiber Laser utilizes AMADA’s revolutionary Locus Beam Control to achieve infinite locus patterns to ensure optimum beam shape control for each specific cutting application. The HRB 1003 ATC Press Brake is equipped with AMADA’s patented ATC, making it the ideal solution for variable lot sizes and the seamless introduction of rush jobs. The BREVIS 1212 AJ compact 3 kW fiber laser is loaded with a range of machine features to support high-speed processing, easy material loading, with a footprint and capacity to efficiently accommodate small cell manufacturing.

AMADA will also feature Influent by AMADA, which provides shop floor visibility like never before by integrating everything in a manufacturing environment, eliminating the barrier between the office and the shop.

3D Metal Printer for Safe, Easy Additive Manufacturing

Alpha Laser US’s (Meadville, PA) AL-3D METAL 200 ensures additive manufacturing without direct powder contact. The company will be in Booth B36071. The closed powder circuit ensures more safety at work because the operator doesn’t come into contact with the powder during the entire printing process. Specifically developed for the precision mechanics, medical technology, dental and jewelry industries, as well as research and development laboratories, our 3D printer offers optimum detail accuracy, precision and maximum safety in handling the laser and the metal powder.

Features at a glance:

- Very fine laser spot for finest and complex geometries

- Powerful laser

- High powder yield

- Exact printing process with the intelligent software AL3D-OS

- Footprint of just 600-x-600 mm

- Closed gas-circuit for a reduced gas consumption

- Little energy consumption

AL-3D cartridge:

Intelligent cartridge system for safe and economical powder handling.

- Material supply made easy

- Fast process preparation

- Plug & Play – transfer of material information to the printer

- Unmatched material utilization

- Ideal for high-priced materials and precious metals

AL-3D cabin:

The unpacking station.

- High operational safety for the user by a closed process chamber

- Clean separation of the sintered component from the residual powder

- Collection of residual material for possible reuse

- Ergonomic workplace

Saws and Ironworker Save Your Shop Time and Money While Increasing Production

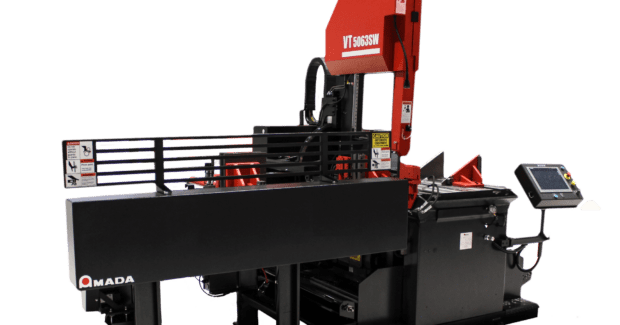

AMADA MACHINERY AMERICA, INC. (Brea, CA) has more than 70 years of industry experience and is committed to helping customers deliver dependable service and top-quality work with exceptional sawing solutions. While AMADA MACHINERY takes great pride in its legacy, it is their drive and commitment to continuous improvement that sets them apart. AMADA MACHINERY works to achieve market-leading quality with reliable productivity. Stop by Booth A1114 to see and hear what their latest and greatest products are.

On display at the show will be a few of the manufacturer’s industry leading Fabricating Vertical Tilt-Frame Saws, including the VT4555M with cutting capacity of 18”-x-22” at 90° with a 1-¼” blade, and the VT5063SW with cutting capacity of 20”-x-25” with a 1-½” blade. This saw will display a compact material handling system, with an infeed and outfeed table, showing off automatic material cuts. The saw will also showcase its Offline Program & Nesting software, making the operator’s job more efficient by being able to program thousands of parts and jobs offline. The blade that is specially designed for these Vertical Tilt-Frames is called the Eagle Beak VTR. The maximum pitch of this blade is two times the minimum pitch making the blade adapt well to various shapes and sizes. The Vertical Tilt-Frame line is backed by more than 110 years of unsurpassed performance, and is manufactured in Oshkosh, Wis.

AMADA MACHINERY will also feature a MSIW60D Spartan Ironworker. The Spartan Ironworker has five workstations, with LED lighting, and has the strongest stripper in the industry.

AMADA MACHINERY’s team has shown commitment and improvements in pushing the product lines to become their best versions. If you are looking to save time and money, while increasing production, then look no further. AMADA MACHINERY AMERICA keeps your best interests in mind while maintaining the philosophy of “Growing with Our Customers.”

Updated Laser Series Chillers

Chase Cooling Systems (Washington, PA) has updated its LASER SERIES and will have a new chiller unit from the series on display at FABTECH at Booth A4923. The renewed LASER SERIES contains chillers with capacities from 0.5 tons-to-25+ tons. The best features of the previous series remain, such as the dual cooling circuits and individual pumps. Additional features include wheel kits and larger size models. The compact footprint allows users to get more out of a single unit. Each cooling circuit is fully independent of the other and can be set to different temperatures.

For applications requiring greater cooling capacity, chiller units can be combined to create a larger system. “After working with laser manufacturers for years, we’re perfecting the unique requirements of lasers and the laser industry,” said Chip Miller, sales manager at Chase Cooling Systems. “This new series is an exciting progression of our chillers.” Chase Cooling Systems provides quality industrial chiller equipment for a wide range of process cooling needs. Products are available to serve a variety of applications and industries.

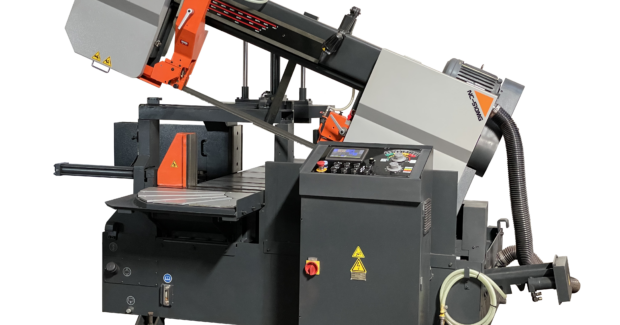

Cosen Saws to Spotlight Cutting-Edge Products

Cosen Saws (Charlotte, NC) will showcase its industrial metal cutting band saws at Booth A5126. Cosen Saws is a global leader in the manufacturing of premium industrial cutting solutions.

Attendees of FABTECH can also expect an unparalleled experience at the Cosen Saws booth, where they will have the opportunity to explore an impressive array of advanced cutting solutions designed to optimize production processes, increase efficiency, and deliver superior performance. Highlighting the product lineup, Cosen Saws will showcase new and original band saws including the NC-510MG, the G320 and the V-1822.

The NC-510MG – Automatic Horizontal Scissor Style, Mitering Band Saw has a capacity of 13″-x-20.”

It is a high production, fully programmable, automatic miter cutting band saw. It is a heavy-duty machine that fits the needs of any manufacturing environment with its full capacity bundle clamps as a standard feature.

The G320 – Fully Automatic Horizontal Dual Column Band Saw has a capacity of 12.8″-x-15.” It is considered the premier saw of Cosen, with its combination of rigidity, state-of-the-art software, technology and affordability. The saw utilizes a true stainless steel dual column design and is perfect for cutting in high production settings.

The V-1822 – Manual Vertical Tilt-Frame Band Saw has a capacity of 18″-x-22.” With the growing popularity of vertical saw design, Cosen’s V-1822 takes the renown tilt-frame design and applies it to a reliably constructed yet small footprint. The manual saw design allows you to control the cutting angle up to 60° in both directions.

Visitors to the Cosen Saws booth will have the opportunity to interact with these machines and our team of experts, who will be available to provide in-depth product demonstrations and answer questions. We will also organize live cutting demonstrations, showcasing the speed, precision, and reliability of the saws firsthand.

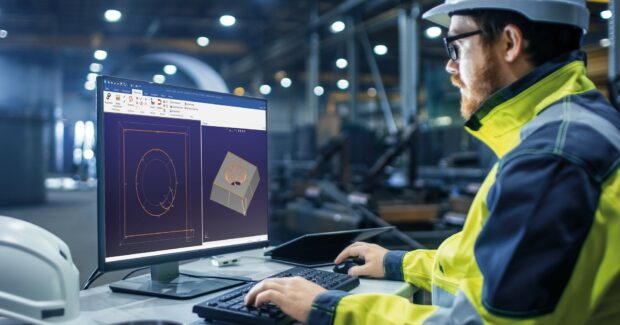

Software Options Provide a Core Tool for Sustained Growth

ECI Software Solutions (Fort Worth, TX), a leader in cloud-based business management solutions, will showcase its M1 and JobBOSS² solutions at Booth A4909. ECI’s Alora Machine Intelligence Platform and International Traffic in Arms Regulations (ITAR)-compliant (M1 and JobBOSS²) cloud platforms will also be on display.

ECI’s JobBOSS² is an award-winning, cloud-native enterprise resource planning (ERP) solution for the job shop and make-to-order segment of the manufacturing market. The JobBOSS² ITAR solution is designed for users that assist manufacturers serving the U.S. government’s aerospace and defense needs with maintaining their compliance. Upholding ITAR compliance within ERP systems is critical for job shops that need to focus on delivering the best products and services, while avoiding potentially costly and disruptive compliance failures.

M1 ITAR’s solution will also be featured. Designed specifically for small- to medium-sized discrete manufacturers that leverage Microsoft Azure for U.S. Government and AWS GovCloud (U.S.), this solution allows M1 customers to grow their businesses while maintaining data in a secure cloud environment.

ECI’s Alora, a machine intelligence platform (integrated in both ERPs), connects information from ERP systems with real-time data from the shop floor to provide a complete view of production performance. Utilization rates can increase by as much as 20% within a few weeks, amounting to a savings of $20,000 on average per machine.

New American-made Waterjet; Long Bed Vertical Machining Center to be Showcased

Flex Machine Tools (Wapakoneta, OH) will showcase the FlexCNC: Long Bed Vertical Machining Center for fabricators at FABTECH at Booth A5186. Flex Machine Tools will also unveil an all-new waterjet, which is designed, fabricated and built in America.

The FlexCNC Vertical Machining Center, designed specifically for fabricators, sets a new standard for versatility and efficiency in the industry. With its capability to handle large or long parts, including plate square tubes, round tubes, extrusions, shafts, and more, this machine offers unparalleled flexibility for fabricators of all sizes. Key features and benefits of the FlexCNC Vertical Machining Center include its unmatched versatility and time and cost savings. This revolutionary machine empowers fabricators to streamline operations, achieve superior finished products and increase profitability.

With the FlexJet Waterjet’s exceptional quality and craftsmanship, fabricators can trust in the reliability and performance of this remarkable machine. “We are proud to unveil the all-new American-made waterjet at FABTECH 2023 alongside our revolutionary vertical machining center,” said Nick Kennedy, CEO of Flex Machine Tools. “As a company deeply committed to American manufacturing, we are excited to bring this exceptional machine to the market. The FlexJet Waterjet, with its unique features and outstanding performance, exemplifies the quality and innovation that our customers have come to expect from Flex Machine Tools.”

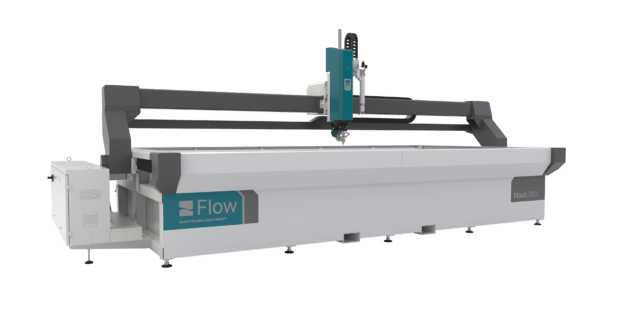

Waterjet Offers Full Access and Capabilities Found in Elite Systems

Flow International Corp.’s (Kent, WA) Mach 200c is a cutting-edge, best-in-class 5-axis cutting system that delivers unparalleled speed and precision at a value-focused price point. Flow will be at Booth A4560. Featuring Pivot+™ waterjet technology, the Mach 200c enables bevel and 5-axis cutting of virtually any material, hard or soft, with up to 60° of motion, and boasts faster, more accurate cutting. Its high-speed motors and drives allow for rapid speed and acceleration/deceleration ultimately providing faster overall cut time. Additionally, the system features an easy load/unload table and a bridge that is canted back to allow for full table access.

ERP Provider Celebrates Five Years for Its Cloud ERP Software

Global Shop Solutions (The Woodlands, Texas), a leading provider of ERP software to manufacturers around the globe, celebrates the fifth-year anniversary of its Cloud ERP product. An investment of high importance to customers, the adoption of Cloud ERP greatly surpassed the five-year forecast. The company will be at Booth A3142.

Designed to make technical support easier and reduce the total cost of ownership for manufacturers, Cloud ERP simplifies the software through increased speed, improved accessibility, stronger security, automatic data and systems backups and more. Said George Thuo, director of cloud technology for Global Shop Solutions: “Like most new Global Shop Solutions products, our Cloud ERP is a result of listening to customers and responding to their needs. Several years ago, a growing number of prospective ERP buyers began asking if our ERP system was offered in the cloud. Based on the demand, I assembled a team to develop the product, which we launched in 2017. Five years later I am proud to say we have more than doubled our forecasts for the number of Cloud ERP users and made ERP software better for hundreds of manufacturers.”

In 2017, about 25% of new Global Shop Solutions customers opted for cloud-based ERP. Currently, about 65% of new customers choose that route. Thuo expected these numbers will continue to climb, in large part due to security concerns.

“With cyberattacks increasing in the manufacturing market, cloud-based ERP costs less to protect the integrity of the system, especially for smaller manufacturers who can’t afford to have IT or security experts on staff,” Thuo said. “Our Cloud ERP helps customers avoid malware attacks because it’s protected with the best technology. Going forward, ERP providers will have to integrate security into their product, and the cloud is a great option. We will continue to innovate to protect manufacturers while making their day-to-day life simpler with Cloud ERP.”

Industrial Cutting Products and Software Ensure Increased Productivity and Profitability

Hypertherm Associates (Hanover, NH), a U.S.-based manufacturer of industrial cutting products and software, is gearing up for FABTECH 2023. The combined booth of Hypertherm and OMAX technology brands, located at Booth A4531, will provide visitors with a comprehensive range of plasma and waterjet products. Live demonstrations will feature the ProtoMAX®, MAXIEM® and OptiMAX® abrasive waterjets. Hypertherm Associates will also showcase demonstrations of their software solutions, including ProNest® CAD/CAM nesting software and Robotmaster offline programming for cutting, welding, trimming, polishing, and other robotic applications.

Hypertherm Associates’ products are used by companies around the world to build ships, airplanes, and railcars; construct steel buildings, fabricate heavy equipment, erect wind turbines and more. Hypertherm Associates is a 100% associate-owned company, employing approximately 2,000 associates, with operations and partner representation worldwide.

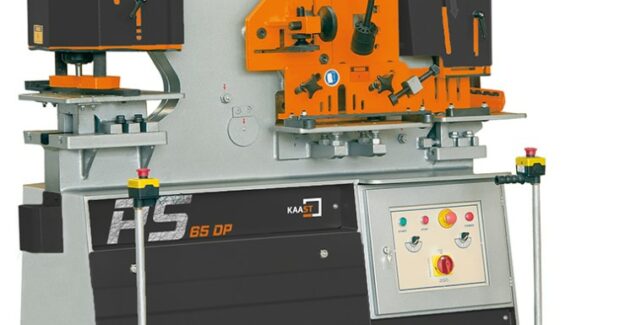

KAAST Machine Tools to Showcase Six Fabrication and Forming Machines

Booth A5167 KAAST’s PS 65 DP 70-ton Ironworker is a versatile machine with 70 tons of pressure and five workstations for punching, shearing and notching.

KAAST Machine Tools, Inc. (Aldan, PA) will showcase six different fabrication and forming machines at FABTECH at Booth A5167 to see the following machines: PS 65 DP 70-ton Ironworker; HPA-P 150/60 150t Simple Press Brake; RBD-4HL 2050/8 NC Plate Roller; HBS 230 DG 9” Dual Mitering Semi-Automatic Band Saw; HBS 440 DG Semi-Automatic Dual Mitering 14” Band Saw; and PBM 50 Angle Roller. Stop by and witness these impressive machines in person.

The PS 65 DP Ironworker is a versatile machine with 70 tons of pressure and five workstations for punching, shearing and notching. It features two hydraulic pistons controlled by independent foot pedals, allowing two operators to work simultaneously. The stroke of the pistons can be adjusted based on material thickness. An automatic backgauge and adjustable rear stop are included.

The RBD-4HL 2050/8 is a heavy-duty four-roll plate roll series that handles materials up to 0.3” thick and 80” wide. It offers overload protection, hydraulic movement of top and side rolls, and a sturdy welded steel frame. The teach-in mode allows operators to record and automate bending processes.

The HPA-P press brakes have steel welded H-Frames with adjustable table heights. They are easy to operate with two hand control and come with a top punch and a 5V die for air bending. The HPA-P presses can be sized to fit most shop floor demands and are in stock and ready to ship.

The HBS 230 DG and 440 DG semi-automatic dual mitering bandsaws provide 9” or 17” capacity, a coolant system, quick-action vice, and variable blade speed and down feed control. Blade changes are simplified with the hydro-mechanical blade tensioning system, and the HBS 440 DG has a digital readout for angle precision.

The PBM 50 DRO features foot-pedal control of the chain-driven bottom dies, with position displayed on a DRO. The upper die is manually adjustable to determine rolling diameter. It is suitable for bending square, flat, and angle iron and can accommodate custom dies for unique profiles. Perfect for smaller job shops and prototyping, it offers vertical and horizontal operation capabilities.

KAAST Machine Tools, Inc. offers one of the most diverse and extensive line-ups of machine tools in the industry. From mills and lathes to grinders and saws, and from brakes and rolls to presses and ironworkers, KAAST makes it easy to find the right machine for your application.

Manufacturer Specializes in Large Format Fiber and CO2 Laser Systems

Kern Laser Systems (Wadena, MN) will be presenting the OptiFlex and the FiberCELL laser systems at FABTECH in Booth A5720. We will have a wide variety of materials and samples on display for attendees to see the Kern difference in person. The OptiFlex is a high performance, large format laser cutting and engraving system. This is the most popular and versatile machine in Kern’s product line. The OptiFlex is ideal for processing of metal, acrylic, wood, textiles and foam while also featuring high-speed engraving capabilities. The FiberCELL is a high performance, Class 2 (enclosed) metal cutting system. This model features the perfect blend of safety and performance. The FiberCELL is ideal for fabrication of mild steel, stainless steel, aluminum, brass and copper. See the Kern difference this year at FABTECH.

Software Solutions Provider to Showcase new Bevel Module for Its Nesting Software

Lantek Systems, Inc. (Mason, OH), a leading provider of software solutions for the sheet metal and manufacturing industries, will showcase its latest CAD/CAM and MES/ERP solutions at FABTECH at Booth A3385. This new module for Lantek Expert Cut CAD/CAM nesting software is designed to streamline the CNC programming of modern TRUMPF cutting machines, providing a more efficient and simplified process for laser machining and the preparation of components for welding operations.

The EdgeLine Bevel technology offers several key advantages over traditional methods that allow specific beveling techniques to be performed without tilting the laser head, reducing overall processing time, and eliminating the need for separate work center processes. The technology also has a significant impact on the preparation of components for welding techniques by enabling the automatic insertion of chamfers and countersinks of various sizes up to 45°, providing a faster and more efficient process with fewer errors compared to traditional manual methods.

“We are delighted to launch the EdgeLine Bevel module for Lantek Expert Cut,” said Mario Rodríguez, Product Manager of Lantek. “This technology represents a major advancement in the field of laser processing and will significantly improve the efficiency and convenience of the manufacturing process. We’re confident that our customers will appreciate the benefits of this module and that it will help them to stay ahead of the competition.”

The EdgeLine Bevel module is currently available only for modern TRUMPF laser machines.

The Latest Tooling Solutions for Increasing Productivity

Mate Precision Technologies (Anoka, MI) will showcase at Booth A2940 the One-Hit-Hinge™ tool that forms two sections of a curl on two separate knuckles, creating a closed circle. When assembled with mating forms, the pin is held securely in place by 360° contact. Because One-Hit-Hinge does not have to be formed straight up and curled down (3-hi style), the hinge diameter can be larger and will not interfere with the machine gap. Use the Mate One-Hit-Hinge to reduce the number of tool hits, increase form size and reduce part cost.

Expand press brake capabilities by forming sheet metal on your press brake with Ultraform PBT™. Ultraform PBT combines Mate’s proven, top-of-the-line Ultraform® thick turret forming system with our newly improved universal press brake forming holder. Produce electrical knockouts, louvers, lance and forms, embosses and stencils on your press brake fast and easy.

The new Screw Pocket Lance & Form tool eliminates the need for a formed flange and the hardware. It creates a form in the edge of the sheet that is designed to receive the screw-thread directly. The hardware and secondary operation are eliminated and both components are fastened together securely.

See Mate’s comprehensive range of punch press tooling for every major CNC punch press: Thick Turret, TRUMPF Style, Murata Wiedemann, Thin Turret and Salvagnini. And the extensive product line of press brake tooling including American Precision Style with Maglock® magnetic safety system, European Precision Style, and WILA TRUMPF Style.

Live Demos of Laser Cutting, and a Suite of Automation Systems

Mazak Optonics Corp. (Elgin, IL) will exhibit live equipment demonstrations on the recently released NEO platform. They will be in Booth A3502. Available in 2D and 3D machine configurations, Mazak’s NEO platform features high-power laser cutting, beam shape/diameter control, and advanced cutting head technology.

An all-inclusive suite of automation will showcase compatible systems available to users interested in optimizing production processes. Visitors will have the opportunity to connect with experienced Mazak personnel to discuss laser and automation solutions tailored to their needs.

Mazak Optonics is a major supplier of laser-cutting systems, offering 50 laser models including 2D, 3D, plus tube and pipe. Mazak is an industry leader in the implementation of emerging laser technologies.

Cutting Machine Works for Both Plasma and Laser Bevel Cutting

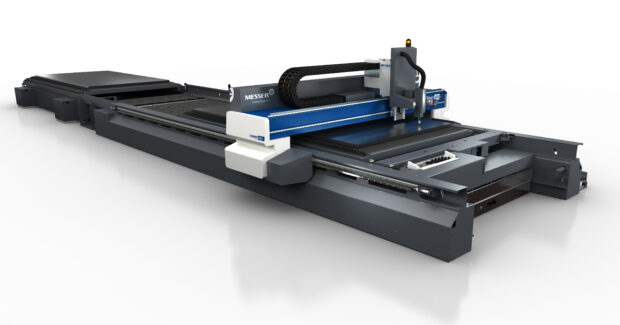

Messer Cutting Systems (Menomonee Falls, WI), a leading global manufacturer of oxyfuel, plasma, and fiber laser cutting machines, welcomes you to visit Booth A3975 to observe the quality, precision, and innovation of Messer Cutting Systems.

The featured Element 400L Unitized Cutting Machine is the latest configuration of the company’s new platform portfolio. Designed to address the large format precision laser industry, this highly flexible machine can quickly process thin-to-thick material. Vertical laser, bevel laser, and even combination laser-plasma options are available to meet customer specific applications.

Our Element 400L show machine will feature laser beveling up to plus/minus 52° utilizing the all-new Bevel-U and a 20 kW fiber laser system. A Kelljberg Q4500 plasma system will also be shown on the same machine. The already high-quality cutting capability of the Q4500 is enhanced when mounted on the performance laser platform of the Element 400L. The included Slagger® self-cleaning table completes this unique hardware platform.

A compact 5’-x-10’ unitized cutting machine, the MetalMaster 2.0, with integrated downdraft table will also be featured. On board will be the Hypertherm XPR300XD plasma torch for straight plasma cutting and new CorePlus gas console to provide high quality marking and cutting on mild steel. The MetalMaster 2.0 provides superior cut performance at an affordable cost.

Messer creates solutions beyond machines. The OmniWin CAM software, which will be demonstrated, is configurable to meet the needs of small shops or those of full-service job shops and OEMs. Application-driven material handling solutions to improve productivity by automating the loading/unloading of plate and to pick, sort, or stack parts will also be shown. The complete end-to-end production environment is then managed by our OmniFab automation software.

Experienced application engineers will be running both cutting machines and demonstrating the latest in plate processing cutting techniques. Sales staff will be available to answer any questions.

Laser Cutting of HRPO Will be Demonstrated by Various FABTECH Exhibitors

Steel Warehouse (Sterling, MI), a steel supplier and distributor, will be showcasing the benefits of its Hot Rolled Pickled and Oiled (HRPO) steel at Booth A3387. Parts will illustrate the enhanced surface finish and cutting-edge quality achieved using HRPO steel. Additionally, Mitsubishi in Booth A2123 and Cutlite Penta in Booth A2194 will be laser cutting Steel Warehouse’s HRPO throughout the show.

Pickling hot-rolled steel removes the flaky scale so the surface is constant and smooth throughout the entire plate. As compared to the blasting process for removing scale, the HRPO surface improves laser cutting, forming, bending, stamping, welding, and painting, delivering both production savings and higher-quality parts.

Improvements include:

- Laser Cutting: Cut up to 25% faster; produce more parts/hour and increase machine capacity

- Grinding: Less weld spatter clean up and no grinding of weld spatter

- Forming: Achieve deeper draw and closer tolerances

- Finish: Glossier finishes

- Paint: Use less primer, with better paint adherence

HRPO is appropriate for applications that use heavy-gauge steel in highly visible areas that would benefit from a better surface finish, as well as improved fabrication. Steel Warehouse is the only company in the world offering HRPO steel plate and sheet from .080″-to- 2″ thick and 30”-to- 96” wide.

New Tool Caddy Ideal for HSK 125A Tooling

Stor-Loc Modular Drawer System (Kankakee, IL) will display the new HSK 125A Tool Caddy in Booth A3458. This unit has 1/4″ UHMW sheets over 3.80 ID tool holder locations. The bottom pan is 2.5″ below the shelf.

The tool caddy is designed with new Tool Caddy Shelf Brackets, which are taller to provide 400 pounds per shelf capacity. This product is ideal for the Top Heavy HSK 125A Tooling.

Stor-Loc Modular Drawer System’s offers a standard delivery schedule of four-to-five weeks. Products are made in the USA with 100% components from the USA.

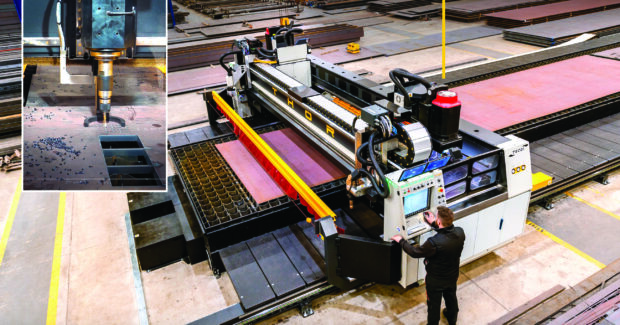

Plate Processing Machine Combines High Performance Thermal and Mechanical Cutting

Tecoi North America (Longview, TX) will feature its powerful and versatile THOR® (Tecoi Hyper Operative Range) plate processing machine at Booth A5178. Designed for heavy-duty thermal cutting applications, THOR integrates plasma cutting and a beveling system, and oxyfuel cutting with an auxiliary tube and profile lathe. Tecoi’s THOR machine also integrates mechanical cutting with the capability to manufacture parts using multiple operations, including: milling, drilling, tapping, countersinking, marking, etc.

High-performance THOR plasma cutting operations include either one- or two-cutting heads and an optional beveling system, as well as oxyfuel cutting with up to 12 torches and an auxiliary tube and profile lathe. Tecoi’s THOR machine has a central XX axis with a path of 24” (610 mm) working on a robust double-beam design. It completes machining tasks with a fixed gantry and the option to fit up two machining heads.

High-performance THOR plasma cutting operations include either one- or two-cutting heads and an optional beveling system, as well as oxyfuel cutting with up to 12 torches and an auxiliary tube and profile lathe. Tecoi’s THOR machine has a central XX axis with a path of 24” (610 mm) working on a robust double-beam design. It completes machining tasks with a fixed gantry and the option to fit up two machining heads.

The THOR plate processing machine features Tecoi’s exclusive BEVEL ARC® beveling system, accommodating angles of ± 50° with maximum precision. The machine also features Tecoi’s DRILTEC® system for drilling and tapping with the option of an automatic tool charger while offering SK 50 tool storage with 20 automated positions or five fixed tools. The cutting table can be equipped with dross collection under the grid and an independent chip collection system for recycling. The cutting grid is comprised of metal supports and a continuous lateral stop for maximum plate holding. Slag can be collected with raisable drawers or by Tecoi’s VIBRATIC® system. Fumes are extracted using Tecoi’s ECOTEC® filters and filtered dust is safely collected in the DUSTEC® system.

Tecoi North America will also highlight its laser plate cutting and processing machines, including the new LS Mega Laser. It provides steel service centers, manufacturers, and fabricators a laser cutting machine with virtually unlimited working length cutting capabilities, while still incorporating all Tecoi’s advanced laser cutting machine innovations, including a double core fiber system, double head cutting technology, and automatic beveling with multitool drilling.

Tecoi designs and manufactures customized solutions for a wide array of companies and industries that comprise a wide range of sectors in metal processing — including steel service centers, steel construction, heavy-duty machinery, the oil and gas industry, shipyards, and for wind power.

WILA Starts Production in North America

WILA USA (Louisville, KY), a leading player in the sector of tooling systems for sheet metals, recently announced the relocation of its North American headquarters to Louisville, Ky., and the establishment of its local manufacturing operations. WILA’s new facility in Louisville features state-of-the-art manufacturing technologies, enabling the company to deliver cutting-edge solutions across a wide range of industries.

This strategic move signifies WILA’s commitment to expanding its presence in the North American market and leveraging the region’s dynamic manufacturing ecosystem. The decision to relocate to Louisville was driven by several key factors. Louisville’s central location within the United States provides convenient access to major transportation networks, enabling efficient distribution of WILA’s products throughout North America. Additionally, the city’s vibrant manufacturing industry, skilled workforce, and business-friendly environment align perfectly with the company’s growth strategy.

WILA’s investment aims to enhance its customer service capabilities and strengthen relationships with existing and prospective clients in North America. By establishing local manufacturing operations, WILA will reduce lead times, increase flexibility, and deliver tailored solutions to meet the specific needs of the region’s manufacturing sector.

“We are excited to relocate our corporate headquarters to Louisville and establish our North American manufacturing operations,” said Hans Willemsen, CEO of WILA. “This strategic move will allow us to strengthen our market presence, improve customer service, and further collaborate with our valued partners in North America. We are confident that our investment in Louisville will accelerate our growth and enable us to better serve the evolving needs of our customers.”

Latest Innovations in Digital-cutting Workflow Automation

There are many ways to optimize digital production and make industrial cutting processes more efficient. Zünd, the Swiss digital cutting-system manufacturer, offers a variety of automation solutions designed for many different production scenarios involving an extremely wide range of different materials. Zund America, Inc. (Oak Creek, WI) will be presenting many of these at Booth A4386. These solutions help automate and standardize anything from cut-file preparation, and control of the cutting and kitting process, to production monitoring and analysis, as well as parts picking, sorting, placing and even logistics. For automated parts removal, a recent addition to Zünd’s product offering is the Robot PortaTable, a movable collaborative robot available with several different end effectors to accommodate different materials and applications.

Another characteristic of Zünd cutting systems on display is versatility. With dozens of different modules and tools, all designed for handling different processing methods and material properties, Zünd cutters/routers can handle anything from extremely detailed and precise cutting of vinyl and films to 4” protective foams and all kinds of rolled, sheeted, and board materials. Because of the modularity of Zünd cutting systems, manufacturers can tailor their machine configurations to perfectly match their immediate cutting needs without impacting their ability to upgrade or expand later.

Zund America’s industrial cutting specialists will be on hand to demonstrate different cutting workflows on the Zünd S3 and G3 machines on display and, above all, discuss the different solutions available for implementing greater workflow automation and improving overall productivity and profitability.

Subscribe to learn the latest in manufacturing.