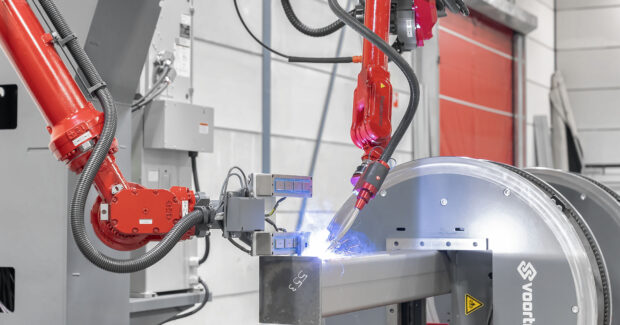

World’s First Automated Fitting and Full-welding Machine for the Steel Fabricating Industry

Voortman Steel Machinery unveils the Voortman Fabricator, billed as the premier welding system for structural steel. Voortman has also introduced DIGI-WELD, a software solution that fully automates the welding preparation process.

Posted: June 12, 2023

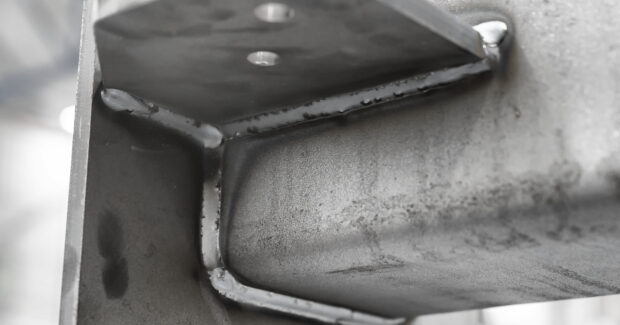

Voortman Steel Machinery is proud to announce the launch of the revolutionary Voortman Fabricator, the premier welding system for structural steel. This new system is capable of producing the most common steel construction profiles – plates, angle irons, tubes, U-profiles, crane runway consoles – and is the world’s first welding robot that can both fit and weld. As a necessary solution to the shortage of welders, this robot allows for fully automated production of welding. Welders who perform this craftmanship can now focus on specialized welding projects instead. The welding process will no longer be interrupted, allowing for better planning and consistent quality.

To further optimize production, Voortman Steel Machinery has also introduced DIGI-WELD, a software solution that fully automates the welding preparation process. This saves time with its analysis and correction of 3D models for welding information at just one click. “The Voortman Fabricator can run 24 hours per day while delivering consistent quality” says Henk Maassen van den Brink, Sales Director at Voortman Steel Machinery. “DIGI-WELD makes the Fabricator the most accessible welding system in steel industry.”

The Fabricator is easy to integrate into any workshop and does not take up much space, making it an ideal solution for companies facing the shortage of skilled welders. It is the perfect combination of technology and skilled professionals, allowing welders to focus on more challenging and specialized welding work while the Fabricator handles repetitive and heavy welding tasks.

The Fabricator is easy to integrate into any workshop and does not take up much space, making it an ideal solution for companies facing the shortage of skilled welders. It is the perfect combination of technology and skilled professionals, allowing welders to focus on more challenging and specialized welding work while the Fabricator handles repetitive and heavy welding tasks.

The introduction of this advanced technology into structural steel production will revolutionize how companies approach their projects while ensuring exceptional results every time. It offers increased reliability compared to manual processes with its ability to complete multiple tasks simultaneously while still maintaining accuracy and precision each time.

Subscribe to learn the latest in manufacturing.