Work Smarter to Achieve Consistent and Higher Surface Quality

Abrasive products and power tools get the job done faster, safer and with ergonomically friendly designs for operator comfort.

Posted: June 16, 2023

METAL FORMING & FABRICATING

Recent advantages include breakthroughs such as simplified robot programming, upgrades in grains and bonding technology, and lightweight and small devices that can remove material from the tightest of spaces.

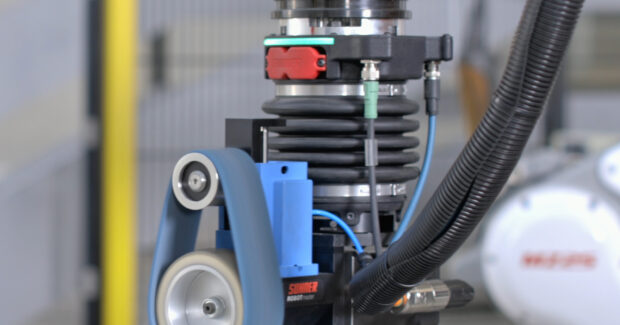

New Robotic Electric Force Compliance System

Suhner USA, Inc.’s (Rome, GA) new EFC-02 combines a century of Suhner’s abrasives and material removal expertise with smart automation for the highest surface quality results. The fully electric EFC-02 delivers precise, constant force throughout robotic grinding, sanding, and deburring processes – resulting in superior, consistent surface quality.

As with any end-of-arm tooling, the EFC-02 connects a grinding machine – angle grinders, orbital sanders, angle polishers, straight grinders and others – to the robot. What makes Suhner’s system unique; however, is its compact design and fully electric operation.

The lightest and smallest in its category, the EFC-02 can be used for material removal or surface finishing even in tight or narrow spaces often found when processing stainless tanks and vessels for the food and pharma industries and more. Suhner engineered the EFC-02 for simple robot programming for setting up even complex processes using an intuitive web-based interface or Fieldbus communication. This includes defining target force, payload and stroke values. Advanced functionality that is in line with the vision behind Industry 4.0 includes a visual LED indicator that tells users whether the grinding wheel is in contact with the surface or not and when the stroke is at 50% to ensure maximum compensation, among other critical operational information.

www.robotic-grinding.suhner.com

Enhanced Grinding and Combination/Pipeline Wheels Offer Best Class Performance

Saint-Gobain Abrasives (Worcester, MA) offers the newly upgraded Norton Gemini® Grinding and Combination/Pipeline Wheels which offer the best performance in the aluminum oxide wheel market. Enhanced Norton Gemini wheels feature a new premium alumina grain for a 15% faster cut rate. Advanced bond technology and wheel hardness are designed for making fast cuts and provide up to 60% longer life and metal removal per wheel compared to previous generation products.

The upgraded wheels are designed with ergonomics in mind, offering a controlled yet aggressive feel. Also, the wheels have been updated with large, industry standard icons that cross language barriers, and are an on-the-wheel reminder of proper machine selection, safe usage and required personal protective equipment.

These wheels are a good choice for grinding 400 series stainless, and hard-grade carbon steel applications including weld repairs, flashing, multi-pass welding for pipefitting and notching. Key market segments are metal fabrication and welding, as well as oil and gas/ pipeline. Offhand stock removal, smoothing welds, beveling, and notching are all ideal applications.

Enhanced for pipeline applications, these wheels feature a bond that has been optimized for 30° angle grinding and 90° angle notching. The wheel construction is more dense and thinner, making it an exceptional choice for multi-pass welding with tight clearances.

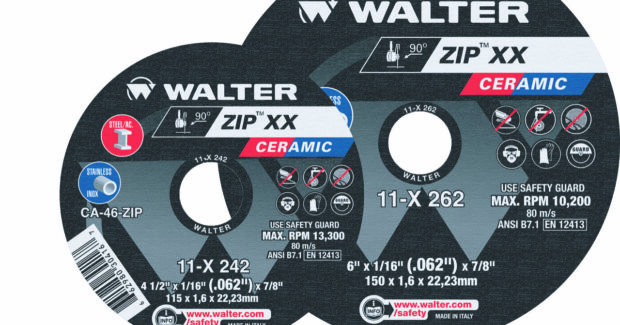

New Breakthrough Cut-off Wheel

WALTER Surface Technologies (Windsor, CT), a provider of metalworking solutions, offers a new cut-off wheel designed to last longer and to increase productivity. The ZIP™ XX outlasts other industry-leading ceramic wheels by at least 30% and delivers the most cuts per wheel, thus reducing changeovers and downtime.

The ZIP XX is a slightly thick 1/16” ceramic wheel with premium reinforcements that make it safer and more durable, all while not compromising speed. Thanks to its unique formulation of 100% self-sharpening ceramic grain, it cuts up to 10% faster than aluminum oxide wheels. It is engineered with the SMART RESIN™ technology, which allows the wheel to expose the fresh grains at the optimal moment to maximize longevity and sharpness. It also delivers smooth, clean cuts every time by minimizing the need to rework the piece as well as the risk of metal overheat or discoloration.

This wheel is made of ceramic micro-crystals with pre-set fracture points that optimize the balance between cutting speed, durability and high performance. Compatible with steel, stainless steel, and hard alloys, this new wheel is now available in 4.5”, 5”, 6” and 7” diameters.

Air Powered Abrasive Belt Machine Converts to a Die Grinder or Drill

Dynabrade, Inc.’s (Clarence, NY) Dynafile II air powered abrasive belt machine features a grinding head that pivots 360°, making this tool excellent for getting into hard-to-reach areas. The Dynafile II features a 20,000 rpm direct-drive air motor which powers abrasive belts 1/4″-to-3/4″ x 18″ long. The ergonomically designed motor handle has a 7° pitch to help prevent wrist and arm fatigue. The tool features quick and easy abrasive belt change, interchangeable contact arms and trouble-free belt tracking. The tool also has a thermal-insulated housing, which prevents cold air transmission to the operator’s hand while at the same time reducing tool vibration. Additionally, the air motor easily converts to a die grinder by adding a ¼” collet, or to an air drill by adding a chuck.

A versatility kit is also available which includes the tool, an assortment of contact arms, abrasive belts and a 1/4″ collet, all in a durable carrying case. Dynabrade has been supplying abrasive power tools to industries worldwide for more than 55 years. Made in the USA.

Subscribe to learn the latest in manufacturing.