Mazak Optonics Invites Fabricators to Discover More

Variable beam shaping fiber laser technology, and the redesign of automation solutions to better handle part sorting are among the advances that position Mazak Optonics for the future.

Posted: June 15, 2023

SUPPLIER PROFILE

Since fiber laser cutting systems became readily available more than a decade ago, fabricators continue to demand higher power levels and faster cutting systems to meet their production needs. However, while achieving higher cutting speeds and higher productivity, fabricators also demand a high-quality part, and these higher speeds can sometimes result in a deterioration of cut quality.

Back in the days of CO2 laser cutting systems, the edge quality of parts was beautiful, said Al Bohlen, president, Mazak Optonics Corp. (Elgin, IL). Fabricators continue the quest for fiber laser cutting systems to go faster but also desire finishes like those produced on the CO2 laser cutting systems.

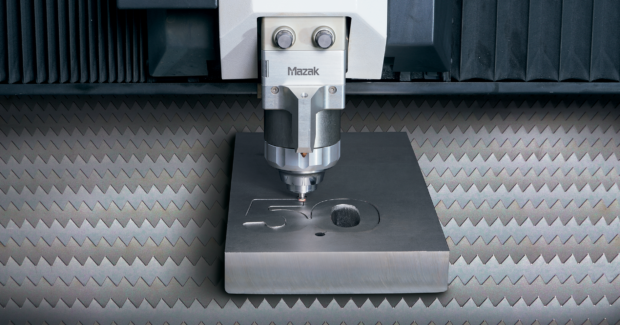

To address customers’ needs for fast cutting speeds resulting in high-quality cut parts, Mazak Optonics has focused on beam shaping technology. The company is a leader in the manufacture of advanced laser-cutting solutions including CNC controls and automation systems.

With Mazak Optonics’ variable beam parameter product, fabricators can change the mode and the heat profile of the beam, as well as the way the heat spreads across a part so it doesn’t reside just in the center of the part or the outer edge of the part. “By having control in this way, you deliver a much higher quality part, in addition to simply going faster,” Bohlen said. “We are one of the leaders in this.”

This beam shaping technology provides advantages when cutting both thick and thin materials, offering a higher cutting speed resulting in superior edges on parts, avoiding a possible secondary finishing process.

Bohlen pointed out there are more manufacturers in the marketplace offering fiber laser cutting systems. Some of the manufacturers offer basic fiber lasers and are not able to deliver the variable beam parameter product like Mazak Optonics does. These companies focus instead on power and not on developing a better high-quality cut part. Bohlen added that Mazak Optonics does offer higher power machines in its product roster and builds a 20 kW machine, which will be on display at FABTECH 2023. “We could have introduced that [machine] two years ago, but we wanted to bring the variable beam parameter product to the market, which does not exist on other lasers,” Bohlen said.

One of the machines equipped with the technology to control the beam shape and beam diameter is the Mazak OPTIPLEX 3015 NEO, a 2D fiber laser-cutting system. The NEO is available in 15 kW, 10 kW, 7 kW, and 4 kW power levels. The NEO machines have large sliding front and side doors so operators can access the entire work area.

The machines are equipped with several Intelligent Functions, which includes nozzle changer, nozzle centering camera, and camera assisted part nesting. The camera assisted part nesting quickly processes additional parts on demand.

The NEO’s new MAZATROL SmoothLx CNC control features a large 21.5” screen and touch panel. Dual monitors allow multiple applications to be performed. The control also rotates, which enables operators to work from the front or side of the machine.

Bohlen said Mazak Optonics, like other manufacturers of fiber laser cutting systems, continues to research and develop alternatives to the assist gasses used in laser fiber lasers, which consume more cutting gasses than their CO2 predecessors.

One alternative is using high-pressure air to cut with instead of nitrogen. Bohlen said the method uses compressed air to develop the high-pressure air, which is “free,” meaning fabricators do not have to pay gas suppliers for their assist gas usage. “In addition to high pressure air cutting we are always looking for alternative ways to reduce the total cost of operation to run the laser,” Bohlen said.

High-pressure air systems are different than standard air compressors commonly found in shops. High pressure air compressors have a refrigerated air dryer, and a high pressure boost pump and advanced filtration providing clean dry air free of contaminants, which is required in the cutting process.

Another difference between high-pressure air systems and shop air compressors is the level of psi. Mazak reports that an air booster can deliver up to 400 psi allowing the laser to cut a wide range of materials and thicknesses.

Automation is the Future

Mazak Optonics is also heavily involved in the development of advanced automation regarding material handling assisting fabricators in managing and overcoming skilled worker shortages. Bohlen pointed out that there is a huge gap in highly skilled, high-quality workers who can work with lasers and robotic welders, as examples. He said in the fourth quarter 2022, there were nearly 780,000 unfilled manufacturing positions in the United States, according to the Bureau of Labor Statistics. Manufacturers are struggling to fill production, middle-skill and engineering jobs. “These workers don’t exist,” Bohlen said. “We have to address this with automation. We have to bring automated solutions to run an industrial laser, and not just loading systems but also sorting systems.”

Mazak Optonics is working on implementing solutions such as robots, whether to pick parts off the laser table individually, or pick, sort, and stack parts to be delivered to the next operation, such as welding or painting. “This is a big emphasis for us,” Bohlen said. “It is the single largest growth area for Mazak.” So much so that visitors to FABTECH 2023 will notice a significant change to Mazak Optonics’ exhibition booth this year. Bohlen said that nearly half of the booth will feature new automation solutions, including robotic part sorting.

Bohlen noted that Mazak Optonics has been operating in North America for more than 30 years, and customers are familiar with the company’s reputation for building laser fabrication machines. They can also count on the company’s automation solutions. Customers are looking for quality laser cutting systems but also seeking solutions for loading, unloading and sorting, Bohlen noted.

“We are often winning that customer because of our automation solutions,” Bohlen said. “We are going to lean into that.”

Regarding its history in automation, Mazak was the first manufacturer to introduce laser cutting machines into a Flexible Manufacturing System. Automated systems create flexibility in a shop’s capacity enabling lights-out operations where operators do not need to physically oversee the systems. Mazak finds companies typically realize up to a 50% increase in capacity with automated solutions as compared to standalone machines.

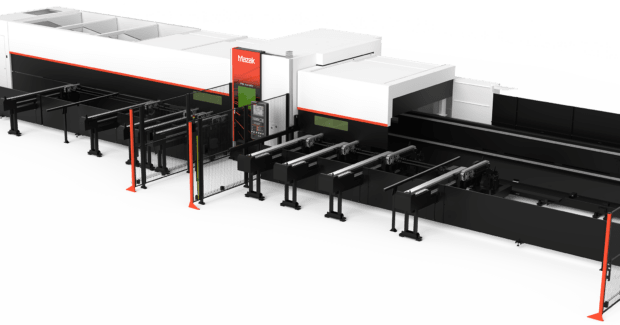

Mazak Optonics’ automation solutions roster currently includes manufacturing cells and several machine lines, such as the M-Series and the K-Series.

The M-Series expands the range of applications including conveyors, over/under carts and labelers. The system features a small footprint and highly customizable configurations. There are also reverse flow configurations available regarding specific machines. The series can be integrated into a Mazak Automated Storage/Retrieval System, which means additional capacity.

The K-Series makes use of vertical space so shops can maximize their floor space. The expandable design allows the customers to grow from load/unload to a one material tower and two-tower storage system with all the cut parts returning to the towers. The K-Series also offers reverse flow configurations for specific machines. The series also works with the Automated Storage/Retrieval System.

Additional automated solutions from Mazak Optonics include the L-Series, the C-Series, Laser Flex, the Automated Storage/Retrieval System and other solutions.

Mazak Optonics’ engineers continue to listen and respond to customers’ requests in overcoming challenges. Bohlen provided an example of how Mazak Optonics assisted a customer in overcoming challenges when handling thin materials. During the last few years more manufacturing industry sectors have increasingly embraced fiber laser cutting systems for the ultra-fast cutting of thin sheets (22 gauge and 24 gauge), including the HVAC industry.

The customer was experiencing damaged material because suction cups on the automated solution would buckle and pucker the material. There wasn’t really an automation solution that could handle picking up thin sheets without damaging the material, Bohlen said. So, Mazak Optonics re-engineered and redesigned its automation to accommodate for the increases in uses of thin materials to prevent buckling, as the established solutions were designed to support heavier materials often seen in agriculture and construction equipment manufacturing.

The new automation technology allowed some of the largest manufacturers of commercial HVAC, industrial refrigeration, and other products, to handle the thinner fiber laser cut materials without damaging them. With the new automation solutions, Mazak Optonics has expanded the ways it can serve emerging markets.

The Past Helps Build the Future

Mazak’s efforts to better serve its customers are based on more than 100 years of experience and tradition. The Yamazaki Mazak Corp. was established in 1919 in Oguchi, Japan, which is the world headquarters for the Mazak Group of companies. Mazak Optonics specializes solely in laser-cutting processes for the metal fabrication, structural steel and construction markets. Products include a complete range of 2D and 3D laser machines. In Elgin, Ill. in 2009, Mazak established one of the largest laser-dedicated technology centers in North America.

“Being located in North America for more than 30 years, and with more than 100 years in business, Mazak has the infrastructure — the people, facilities, application departments” — to offer outstanding customer service, “Bohlen noted. One of the key tenets of Mazak’s philosophy centers on outstanding customer service, which Bohlen said ranks above R&D, and developing new cutting-edge technologies and automation solutions.

“Why I go on is that over the last several years there has been a large increase of other laser cutting system builders,” Bohlen said. “It used to be 10 different companies; now there are more than 30.” Mazak is not saying that these machines are not good — the point is that there are three times more of these providers in the market in the last 10 years. Many of these companies do not have multiple millions of dollars invested in the infrastructure needed to support fabricators and their machinery needs. Many don’t have service departments, training departments or applications departments.

“Our longevity is due to supporting our customers,” Bohlen said. A recent example is the 25,000-square-foot expansion to Mazak’s customer service area during the pandemic. The company also carries an inventory of $9 million in spare parts to better serve customers’ needs. Bohlen pointed out the customer service equation isn’t a matter of what part of the world these newer companies come from, but if they have the infrastructure to remain in business in the long term.

{sidebar}

Mazak’s Laser-dedicated Technology Center

Mazak’s North American Laser Technology Center in Elgin, Ill., is one of the largest such facilities in North America dedicated to laser technology. Applications development, training and a customer support call center comprise 37,500 square feet of the center’s 50,000 square foot total footprint. The $25.6 million investment bodes well for the expansion of the fiber laser cutting sector in North America. At the center, Mazak collaborates with customers to overcome application development challenges, as well as educate fabricators as to the advantages of lasers.

Among its offerings, customers can work with application engineers on optimizing processes and creating manufacturing solutions. Customers can test cut parts on advanced lasers. They can also develop ideas in secure settings to ensure the privacy of their systems. The center also features 18 laser machines available for operator training.

Subscribe to learn the latest in manufacturing.