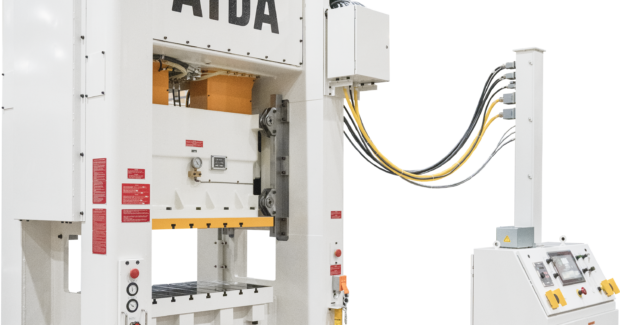

FABTECH 2023: New Mechanical 110-Metric Ton, 300 SPM Stamping Press

AIDA-America’s newly designed two point, 110-metric ton, unitized frame press is capable of speeds ranging from 120-to-300 strokes per minute.

Posted: June 30, 2023

AIDA-America NSX-1100, 110-Metric Ton, 300 SPM Stamping Press

AIDA-America, metal stamping press manufacturer in Dayton, OH, USA, is introducing the NSX mechanical stamping press at FABTECH® Chicago 2023. This newly designed two point, 110-metric ton, unitized frame press is capable of speeds ranging from 120 to 300 strokes per minute. The automotive, appliance, hardware, consumer goods industries, and all industries who depend upon consistent high-volume production, will benefit from the applications of this press system. Accuracy is ensured by a zero clearance, lubrication free, eight-point roller slide guide system and by dual counter rotating eccentric shafts. Press and die integrity are protected by AIDA’s metal seal type Hydraulic Overload Protection (HOLP), the fastest acting HOLP in the industry at 10 milliseconds to zero pressure.

Additional AIDA NSX press features include:

- Low deflection, rigid unitized steel frame construction

- Cast iron slide with detachable slide face

- Induction hardened main gears

- Inboard mounted carbon fiber counterbalances

- Quill mounted flywheel

- Pneumatic combination clutch-brake unit placed outside of the flywheel

- Oversized ball type connection points to minimize drivetrain clearances

- Recirculating oil lubrication system with cycle monitoring

- Variable frequency main motor

- 65mm Stroke length

- Bed size of 50 inches L-R

- Slide and bolster JIC T-slots on 6 inch centers

- Floor mounted design for quick and pit-free installation

- Eight programmable limit switch (PLS) circuits

- Quick access, extended range, powered slide adjustment allows easy die access, with auto slide adjust option to maximize slide adjustment range capability

- Plug-and-play control junction box with standard Rockwell Allen-Bradley control, or optional Link OmniLink 5000 or Wintriss SmartPAC controls

Further NSX options follow:

- Peak / reverse tonnage monitor

- Die protection, 8 or 16 channel

- Eight additional PLS inputs

- Operator T-stand control

- Front and rear light curtains with mesh side guards

- Front and rear die doors

Locally engineered at AIDA-America in Dayton, OH, the NSX is designed to meet the demands of high-volume stamping operations. See this press in action, running at its top speed of 300 spm in AIDA-America booth D40902.

Subscribe to learn the latest in manufacturing.