Cutting-edge Advances Bring About High Quality, Clean Edges

The high-quality seams produced by bevellers and uniform notches produced by notching equipment mean fewer errors and less rework.

Posted: June 17, 2023

METAL FORMING & FABRICATING

Powerful machines and software innovations speed up processes in your shop, and still deliver high-quality edges, as well as gap-free fits.

New Beveler Balances Power, Smooth Operation and Quality

Quality edges without dust and sparks — the new TruTool TKA 1500 beveler from TRUMPF Inc. (Farmington, CT) offers powerful, yet smooth operation and high-quality beveled edge results in a clean, dust-free process. The robust TKA 1500 creates precise bevel lengths of up to 15 mm at angles of 30, 37.5, 45 and 60 degrees. The bevel length can be set as required without the need for additional tools. Operators can achieve instant high-quality, repeatable edges without reworking. The TruTool TKA 1500 can be used to produce clean visible edges, break sharp edges, apply a radius, or prepare a weld seam. The efficient milling process is up to five times faster than other beveling processes. Also, the process does not deform or oxidize the material and is emission-free and dust-free, which enhances the finished product and creates a better user environment. The TKA 1500’s ergonomic guide and motor handle make it safe and easy to use. A new guide fence accessory acts as both a fence and a chip protector. The optimized scale ring has an unobstructed view, making it even easier to adjust the bevel length. The handle is shaped for ease of use from any position, which makes it a versatile product for any fabricator looking to improve production. The TKA 1500 is robust and powerful – the machine has a 2,600-watt motor with a high-quality gearbox for high power – while ensuring a high level of smoothness and stability for users.

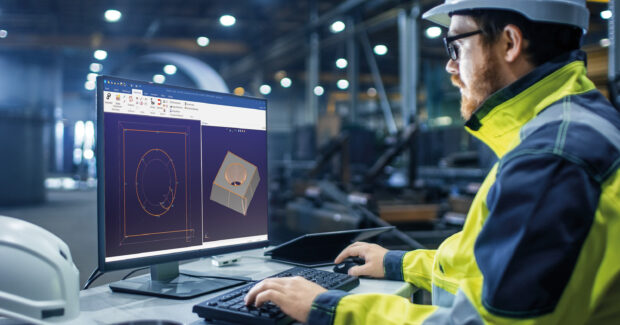

New EdgeLine Bevel Module Added to Expert Cut Software

Lantek Systems, Inc. (Mason, OH), a leading provider of software solutions for the sheet metal and manufacturing industries, has launched a new module for its Lantek Expert Cut CAD/CAM nesting software. The EdgeLine Bevel module is designed to streamline the CNC programming of modern TRUMPF cutting machines, providing a more efficient and simplified process for laser machining and the preparation of components for welding operations.

The EdgeLine Bevel technology offers several key advantages over traditional methods that allow specific beveling techniques to be performed without tilting the laser head, reducing overall processing time, and eliminating the need for separate work center processes. The technology also has a significant impact on the preparation of components for welding techniques by enabling the automatic insertion of chamfers and countersinks of various sizes up to 45°, providing a faster and more efficient process with fewer errors compared to manual methods.

CNC Technology Reduces Thick Part Beveling to a Single Step

An innovative beveling technology from MicroStep, known as Additional Beveling Process (ABP), is eliminating the need for costly robots by providing precise subsequent beveling with gantry-type CNC cutting machines. Offering clear advantages over traditional multi-stage beveling processes, ABP allows beveling to be completed on a single machine generating measurable gains in quality, time, and cost savings.

MicroStep cutting machines are available throughout North America from United Precision Services, Inc. (Cincinnati, OH). John Prevish, the company’s national sales manager, explained that thanks to its unified concept of bevel cutting equipment, MicroStep is redefining thick material subsequent bevel preparation.

“ABP is fast, reliable and applicable to a wide variety of material processing options such as plasma, laser, oxyfuel, and waterjet,” Prevish said. “The technology allows parts to be processed from completely different machines. For example, thick parts cut with oxyfuel can be subsequently beveled by plasma, or parts pre-cut with plasma can be cut with fiber laser. Moreover, the same scanner that is used for ABP can scan and automatically compensate irregularity of pipes, square tubes, beams or domes.”

www.unitedprecisionservices.com

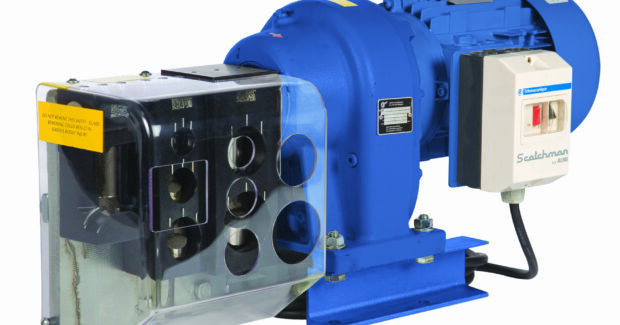

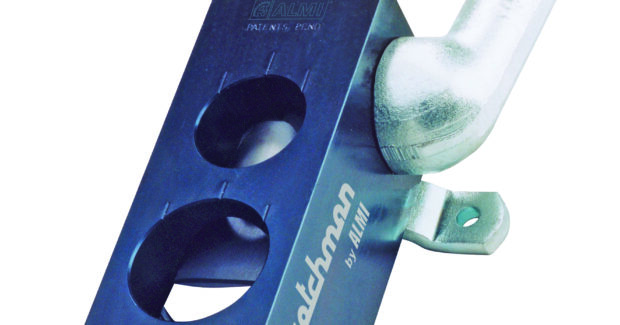

Create the Perfect Notch in Seconds

Notching equipment from Scotchman Industries, Inc. (Philip, SD) is top quality, perfect for double corner joints, great for high production, and backed by Scotchman’s three-year warranty on parts. Ideal for steel, stainless steel, and non-ferrous tube and pipe construction, handrails, gates and fences, car frames, roll cages and more. Each piece is quickly and accurately notched and produces a gap-free fit ready for welding.

The manual and electric notchers are perfect for quick-fit 90° notches. Abrasive grinder/notchers provide the perfect saddle for unique angles on both round and square applications.

Subscribe to learn the latest in manufacturing.