The Route to Flexible Workholding

Grip all your workpieces with powerful, innovative and quicker workholding. Lenzkes to showcase solutions at Eastec 2023.

Posted: May 3, 2023

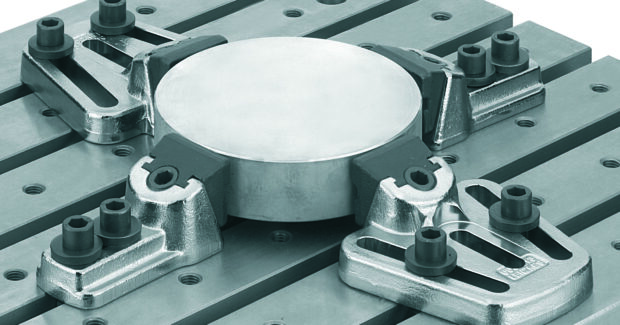

Lenzkes Clamping Tools is known for its high-quality workholding solutions for all types of machines. Products are applicable for machine tables/platen with t-slot and/or tapped holes and feature high clamping forces ensuring quicker and safer changes. The Lenzkes Self Center Clamp provides 0.0016 in. centering accuracy. Application examples include milling and drilling. The device has interchangeable jaws and a base plate with centered tapped hole. The device is hardened alloy steel and provides a clamping force of up to 5,600 lbs.-force.

Quick Setup Workholding Solutions Save Time and Money

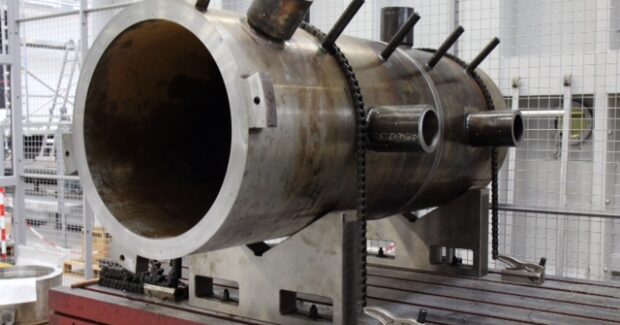

Lenzkes chain clamps provide the fastest and safest way to hold round and bulky workpieces securely in place by low torque settings. The chain clamp product is easy to adjust, which increases productivity by reducing setup time. The MQ150 and MQ160 quick release tools offer exceptional stepless, vertical and horizontal adjustment. The unique arch shaped clamping arm provides multiple options regarding clamping position. The MQ 160 provides a greater stepless horizontal adjustment due to an elongated slot in the clamping rail.

Design Fixtures Successfully with Clamping Tools from Lenzkes

Self Centering Clamps can be mounted on sub plates in various numbers. Lenzkes Multi-Quick Tools can also be used to hold sub plates on the machine table. Sub plates with a lower profile can be fixed safely and quickly with Lenzkes Multi-Quick 60 and 100 Series 8 tools.

Features of Lenzkes Self Centering Clamps:

- Stepless adjustable

- Centering accuracy of 0.04 mm/~.0016 inch

- Interchangeable/replaceable faces

- Base plate with centered tapped hole

- Clamping force up to 25 kN/5,620 lbf

Multi-Quick 60 and 100 Series 8 Features:

- Protected trademark Multi-Quick

- Stepless vertically and horizontally adjustable

- MQ 100 Series 8 — greater horizontal adjustment due to the integrated sliding plate

- Strong clamping pressure for small clamping torque MQ 60 Series 8 — up to 24 kN/5,395 lbf clamping force

- MQ 100 Series 8 — up to 22 kN/4,945 lbf clamping force

Lenzkes Side Clamps SK10/SKQ 10: Quick and safe workholding solution for free surface machining.

Because workholding fixtures for low profile workpieces and free surface machining are in demand, Lenzkes developed and designed SK10 and SKQ10 side clamps offering solutions for workpieces in different shapes and heights.

SK10/SKQ10 Features:

- Side clamps SK10 and SKQ10 made from drop forged alloy steel and available in different styles

- SK10 side clamps can be used and moved parallel to the t-slot

- SKQ 10 side clamps can be used and moved parallel and at any angle to the t-slot

- Clamping forces up to 14,600 lbf for the largest side clamp