Sustainable Products Handle Critical Cleaning Needs

Suppliers of metalworking fluids, cleaners, lubricants and coolants offer breakthrough solutions and equipment to address industry specifications.

Posted: April 19, 2023

Metalworkers are stepping up their maintenance management programs to deal with new machine technologies and materials, as well as climate regulations, and the sustainability goals and targets of their customers.

Future-oriented and Sustainable Solutions for Reaching High Cleanliness Requirements

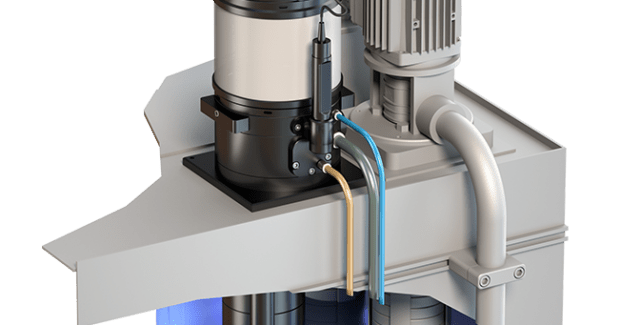

Parts cleaning has become a quality critical manufacturing step in all industry sectors. Companies need to take great effort to reproducibly meet even more demanding particulate and surface tension cleanliness specifications. Ecoclean (Southfield, MI) is answering these requirements with future-oriented parts cleaning solutions. Its EcoCcompact is a highly flexible and compact plug and play machine for solvent cleaning.

EcoCcompact’s features include a large batch capacity, effective washing mechanics and media preparation, energy-optimized system technology with effective heat recovery and various other options. This compact plug-and-play solvent cleaning system operates under full vacuum, which results in a closed loop system with virtually no emissions and allows users to easily switch between hydrocarbons and modified alcohols (semi-polar solvents) as cleaning media. In addition, it requires a footprint of only 10.5-x-5.3-x-8.0’ (L x W x H). As standard, the EcoCcompact can be equipped with two or three fully integrated flood tanks, each fitted with a filtration system in the supply and return lines in the form of bag-type or high-performance filters and bypass filtration. The system can therefore be used from pre-cleaning through intermediate to final cleaning tasks and preservation and achieves results in short cycles. Process technologies integrated as standard, such as vapor degreasing, ultrasonic and injection flood washing, also contribute to this.

Complete and Hassle-free Coolant Management Systems

Jorgensen Conveyor and Filtration Solutions (Mequon, WI) has partnered with Will-Fill, a manufacturer of fully automatic coolant monitoring and managing systems. Jorgensen offers a wide range of standard and customized systems to manufacturers. This strategic partnership allows Jorgensen to offer customers complete and worry-free coolant management systems, such as PermaClean, which provides both filtering and measuring capabilities for an all-in-one solution.

With the addition of the Will-Fill add-on device, a coolant system can provide trouble-free care of metalworking emulsion by combining automatic measurement and analysis of fluid with faultless filling, permanent conditioning and timely reporting. Will-Fill’s components are linked to a high-performance control unit, allowing the device to regulate and adjust the fluid level and the fluid condition automatically. Additionally, it can alert users when attention is necessary via WI-FI or LAN network capability.

Coolant tanks equipped with PermaClean eliminate tank sludge, significantly reducing the labor required for frequent tank cleaning. Plus, when combined with the cyclonic filtration option and a Will-Fill, the system is fully automated and nearly maintenance free.

Precision Cleaning Solvents

KYZEN Corp. (Nashville, TN), the global leader in innovative environmentally friendly cleaning chemistries, offers several products that support several industries and processes, including metal finishing. Two of those products are KYZEN’s METALNOX M6386 Modified Alcohol Solvent Cleaner, and METALNOX M6381 Precision Hydrocarbon Solvent Cleaner.

METALNOX M6386 is a modified alcohol-based solvent blend designed for use in automated vacuum degreasing parts cleaning machines. The cleaner is highly effective on paraffinic and water-based oils, cutting fluids and milling fluids commonly used to forge and cast metal hardware, fasteners and components.

METALNOX M6381 is a hydrocarbon solvent cleaner formulated for use on non-polar soils and is commonly used to clean parts supplied to the automotive, medical, aerospace, and other high-tech industries. M6381 is most effective in vacuum degreasing, immersion, and manual applications.

Both solvents are safe vacuum vapor degreasing solvent alternatives that meet U.S. EPA requirements, while also meeting the cleanliness standards in your process.

Introducing Sustainable, Non-Toxic, VOC-Free Bio-Rust Preventative

Renewable Lubricants Inc. (Hartville, OH) introduces Bio-Rust Preventative Fluid, a bio-based formulation that is environmentally non-toxic, VOC-free, sustainable, and highly effective at inhibiting corrosion on ferrous and galvanized steel. This non-staining, water displacing formulation provides a waxy film that is especially effective in protecting ferrous materials in salt and acid-fume (hydrochloric acid) environments and against humidity. Specially designed biodegradable Bio-Rust Preventative meets the corrosion protection film form MIL-PRF-16173, Class II, Grade 3. They are ideal for metalworking applications where excellent in-house corrosion protection and easy cleaning of parts is essential.

Bio-Rust Preventative provides >120 hours of protection in HCI Acid Fume test, and >80 hours in a 5% Salt Spray (fog) ASTM D117 test. Additional Renewable Lubricants products are available to meet other corrosion inhibition applications. In addition to corrosion protection, these products are used as non-chlorinated metalworking fluids that provide extreme pressure, anti-wear, and lubricity performance in stamping and drawing applications.

Alternatives, Expertise for 3M Novec™ Replacement Vapor Degreasing Fluids

MicroCare LLC (New Britain, CT) offers a wide range of excellent replacements for the 3M Novec specialty cleaning fluids. This comes in response to 3M’s recent announcement that it will discontinue manufacturing all fluoropolymers, fluorinated fluids, and PFAS-based additive products by the end of 2025, including Novec 7100, 71DE, 7200, 72DE, 72DA, 73DE and others.

MicroCare’s fluids have similar, if not superior cleaning performance to the Novec fluids and can clean a wide variety of soils, including oil, grease, particulate, inks, fingerprints and more. They also have similar, if not identical compatibility profiles to help prevent damage to delicate materials. Many of the MicroCare fluids, including its signature Tergo™ MCF (Metal Cleaning Fluid) and Tergo™ GCF (General Cleaning Fluid) are azeotropes, making them chemically stable and nonflammable in both vacuum and vapor degreasers.

Importantly, the MicroCare vapor degreasing fluids are domestically formulated and produced in New Britain. They are readily available, with plenty of capacity to ensure supply, for immediate global shipment without importing issues or delays. They also boast low GWP (Global Warming Potential) and zero ODP (Ozone Depleting Potential) ratings to help reduce greenhouse gas effects and meet strict regional air quality regulations.

In addition, MicroCare provides extensive, in-depth technical support, advice and training around the new fluids.

Subscribe to learn the latest in manufacturing.