Sanding Cobots Change Minds and Lives

Workers at an aerospace company were attracted to cobots primarily because of the unique collaborative element that enables humans and robots to work together.

Posted: April 15, 2023

ADVANCING AUTOMATION

Union shops may have a reputation for being anxious about the introduction of automation. But when that automation is truly collaborative and brings immediate physical benefits to workers, that anxiety can quickly transform into wholehearted endorsements.

Savage Sanding

Sanding is grueling work. And even the best equipped and most ergonomically friendly manufacturing facility cannot prevent manual finishing tasks from taking a serious toll on workers’ bodies. The repetitive motions inherent to sanding cause tendonitis, musculoskeletal injuries and other conditions. Worse still, some workers carry visible scars as reminders of carpal tunnel syndrome surgery on their wrists.

Awkward postures and exposure to vibrations, noise and dust bring additional health issues from a permanent sensation of numbness in the fingers and hands to musculoskeletal injuries and breathing problems.

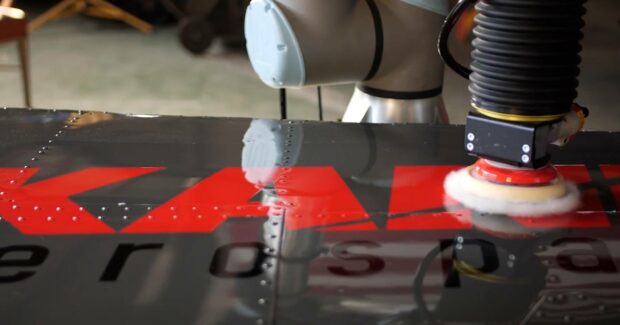

“It’s dull, dirty and debilitating work,” said John Spruce, CEO at Kane Robotics, a Chino, Calif.-based firm that has developed a range of collaborative robot (or cobot)-based sanding, grinding, and finishing systems designed to free workers from the most repetitive and physically challenging tasks.

The main driver of cobot adoption for sanding and other shop floor tasks is the ongoing manufacturing sector labor shortage. According to the December 2022 National Association of Manufacturers’ survey, the No. 1 challenge reported by 75% of manufacturing companies was ‘attracting and retaining a quality workforce.’ This is a problem Spruce has seen throughout his customer base.

“The labor crunch is a real issue for all our customers,” he said. “Sanding is skilled work, but positions are very difficult to fill. On top of that, if someone shows an aptitude for sanding, they often get promoted into even more skilled positions, with the end result that companies are constantly trying to fill those types of roles.”

The pain is felt on companies’ bottom lines too. Every second of downtime lost to sickness and injury has a negative impact on morale and productivity — and costs money.

Traditional Automation Causes Anxiety

The traditional solution to the ergonomics problem in manufacturing is to provide workers with the latest personal protective equipment and to provide breaks, which improves ergonomics, but contributes little in the way of productivity benefits, so this solves only part of the problem.

Another solution is to invest in traditional sanding automation, which presents its own challenges. This type of automation is bulky, requires extensive fencing and guarding, and typically requires a massive capital investment. It’s also more difficult to program and maintain versus collaborative automation. Traditional sanding automation saves human workers from repetitive, dangerous, physically challenging tasks — but only by eliminating their jobs completely. For obvious reasons, this approach doesn’t go down well in unionized manufacturing facilities.

Little wonder then that when Kane Robotics’ cobot-based GRIT XL automated sanding system was first wheeled into a unionized manufacturing facility at a leading aerospace company, management was apprehensive about the reaction among workers and union representatives both.

“Management was extremely concerned that the union would not be happy with automation coming into their facility,” Spruce said. “Those fears were immediately dispelled after testing GRIT in their operations, and within a week the system was approved, with enthusiastic buy-in from workers.”

Cobots Provide a Middle Ground

Cobots are the fastest-growing segment of the industrial robotics market for good reasons: Cobots have significantly lower total cost of ownership and provide faster return on investment than traditional sanding automation. Cobots are also easier to deploy, program, and maintain than their traditional sanding robot counterparts.

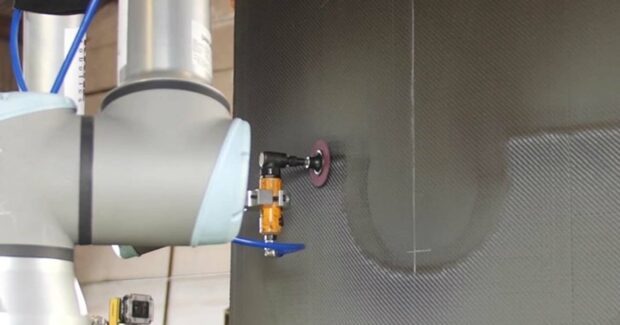

It’s not easy for humans to maintain the same quality of sanding work throughout an entire eight–hour shift. Cobots provide a repeatability that ensures consistent quality and other productivity benefits 24/7.

Moreover, following a risk assessment, cobots can be safely deployed beside human workers without the need for space-hogging safety fences and guarding. Additional benefits include greater adaptability than traditional sanding automation, which makes cobots an ideal fit for high mix/low volume manufacturing and makes it easier for companies to adapt to fluctuating demand and workforce availability.

The workers at the aerospace company were attracted to cobots primarily because of that unique collaborative element that enables humans and robots to work together.

“The workers saw that the cobot is a tool that that they will be operating and not a threat to their jobs; they would retain some tasks, such as loading parts and making decisions about the amount of sanding required on a specific area,” Spruce said. “They saw that their expertise was still required.”

Cobots Change Minds and Lives

After working with the system for a couple of months, a union worker at the facility was asked what he thought of the system, Spruce noted. “He said ‘I love this robot. I’ve got another decade to go in my career before I retire. And with this system, I’ll probably be able to still throw the baseball with my grandkid when I retire. Plus, I won’t be leaning over for the next 10 years sanding stuff.’ We were wowed by this response as it shows the very real positive impact that collaborative sanding automation can have on people’s lives,” Spruce said.

Management was pleased too: the deployment reduced one sanding process from 10-to-12 hours to three-to-four hours, driving greater productivity and throughput at the facility.

Choosing a Cobot

Not all collaborative sanding automation is made the same, so here are a few tips on what to look out for when choosing a cobot-based sanding system.

Look for ready out-of-the-box solutions that provide all the specialized hardware and software you need to get your sanding application up and running quickly, safely and effectively. This will save engineering time that would otherwise be spent on cobbling together different components to create an effective solution. Start your search within an established ecosystem of cobot-based, automated material removal application kits.

Payload and reach requirements will vary depending on the application, but if you want your cobot to handle large sheet metal parts and extend the application potential of the system, make sure that it has sufficient reach and payload capacity. Payloads up to 16 kg (35.3 lbs.) with a reach of 900 mm (35.4”) are widely available today. (For those wanting to handle even bigger payloads, note that a cobot with a 20 kg (44.1 lbs.) payload and 1750 mm (68.9”) reach will hit the market later this year.)

If you want your cobot to handle large sanding end effectors and extend the application potential of the system, you will need to ensure that the cobot you select has sufficient reach and payload capacity.

For heavy-duty applications that require even bigger payloads, there is a cobot with 20 kg (44.1 lbs.) payload and 1750 mm (68.9”) reach on the market.

While cobots are incredibly easy to operate, especially versus traditional automation, easy access to training and ‘How To’ guides can be key to a successful deployment. Make sure that your cobot provider supplies sufficient free, online training resources. Ask for a hands-on demo to see the system in operation before buying —and bring along a sample for the cobot to showcase its abilities on.

Subscribe to learn the latest in manufacturing.