New SeamMonitor System for Precise TIG Tube Welding

Xiris Automation launches a real-time measurement tool that monitors torch tip to weld seam alignment and weld seam size on TIG welded tube mills.

Posted: April 13, 2023

Xiris Automation, a leading provider of innovative camera-based solutions for quality control in the metal fabrication industry, has announced the launch of SeamMonitor™, a camera-based measurement tool that provides real-time monitoring of the torch tip-to-weld seam alignment and weld seam size on Tungsten Inert Gas (TIG) welded tube mills.

Metal tube fabricators who use TIG welding know that precise alignment of the welding torch to the welding seam is critical to achieving high-quality welds with clean edges and minimal weld bead. Occasionally, the seam to torch tip alignment can move over time due to various tensions in the tube, causing it to twist as it is pulled through the weld head. As a result, the weld seam can rotate in and out of position with respect to the welding torch, which may result in defects and production losses.

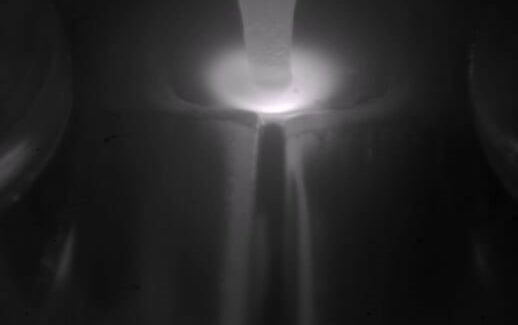

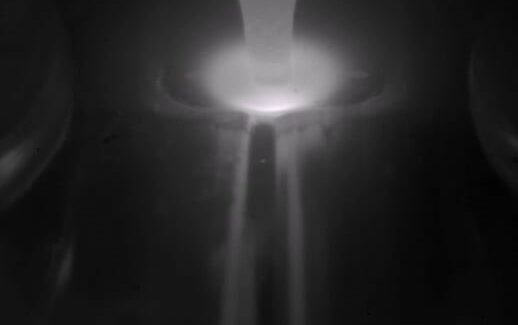

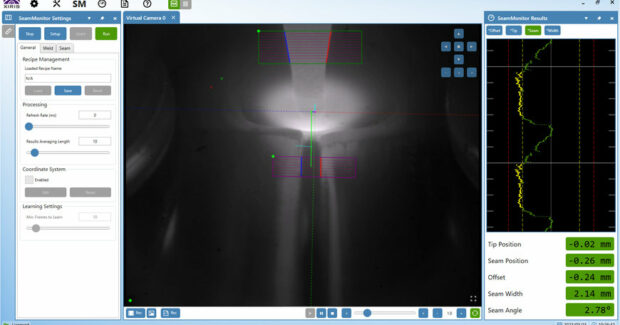

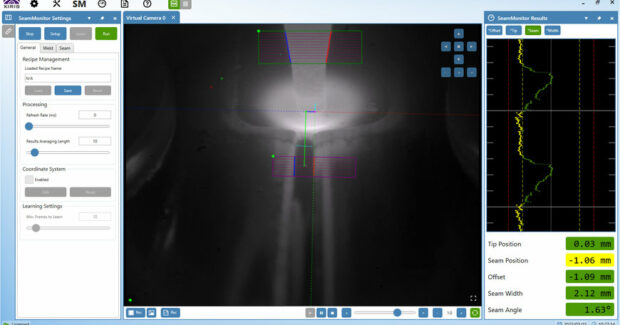

To solve this problem, Xiris has enhanced its SeamMonitor system, which provides a robust solution to monitor tip-to-weld seam alignment on TIG Tube mills. The SeamMonitor combines a High Dynamic Range (HDR) weld camera that can clearly capture the torch, weld arc, and surrounding environment with powerful machine vision measurement software that enables real-time monitoring of the weld seam size, torch tip location, and relative offset between the torch tip and its seam.

The SeamMonitor provides a system solution for use on TIG Tube mills providing warning and error alerts on key measurements to operators or external equipment for process control. The system includes data analysis tools and onscreen graphing of key measurements that can be sent to external equipment using OPC, analog or digital interfaces.

SeamMonitor is built on Xiris’ WeldStudio™ software platform, providing a TIG Tube fabricators a comprehensive process monitoring solution improved quality and reliability of their welding process.

Subscribe to learn the latest in manufacturing.