New One-Hit-Hinge™ Tool Reduces Hits and Part Costs vs. Traditional Methods

Since the One-Hit-Hinge does not have to be formed straight up and curled down (3-hi style), the hinge diameter can be larger and will not interfere with the machine gap.

Posted: April 5, 2023

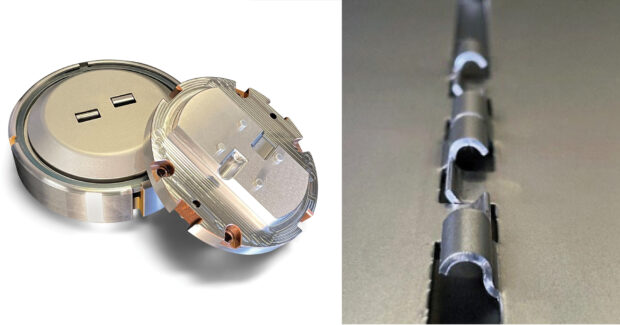

The Mate One-Hit-Hinge™ tool eliminates the headaches of traditional forming hinges on a punch press using two tool sets: one tool forms the pre-curl in two hits, and the second tool closes the hinge. Not only does this take 3 total forming strokes, but the machine gap limits the hinge diameter.

The Mate One-Hit-Hinge™ forms two sections of a curl on two separate knuckles, creating a closed circle. When assembled with mating forms, the pin is held securely in place by 360° contact. Since the One-Hit-Hinge does not have to be formed straight up and curled down (3-hi style), the hinge diameter can be larger and will not interfere with the machine gap. Overall production enhancements include: reduction of the number of tool hits, increased form size and reduce part cost.

The One-Hit-Hinge™ tool is a game-changer for hinge applications such as metal enclosures, access panels, metal cases, and electronic cabinets. It eliminates the need for separate hinges, spot welds, fasteners or other downstream assembly operations. Eliminating the need to attach the hinge also increases accuracy. There’s no chance of that hinge being spot welded in the wrong place or welded joints which can fail in the field.

Mate’s One-Hit-Hinge™ tool is used for mild steel and aluminum ranging from .030 (0.70mm) to .080 (2.0mm) thickness. In addition, it may be suitable for stainless steel in specific applications. The One-Hit-Hinge™ tool is available in most tooling styles:

- Ultra TEC® Thick Turret tooling

- Murata Wiedemann 114 Style and 112 Style tooling

- Trumpf-Style tooling

- Strippit Style Thin Turret tooling

- Salvagnini tooling

www.youtube.com/watch?v=O0YNXuG2OJY

Subscribe to learn the latest in manufacturing.