Create a Supply Chain that will Bend, not Break

The supply chain remains affected by the challenges ushered in with the global pandemic. Take steps to triumph over delays and hold ups.

Posted: April 17, 2023

EDITORS FORUM

What you resist, persists. Sometimes the supply chain feels like continuous chaos — that there is nothing to do but shrug your shoulders and wait for things to change. Consider that metalworking manufacturing operations are speeding up processes by adding the latest machinery, robotics and automation into processes — only to run into supply chain constraints.

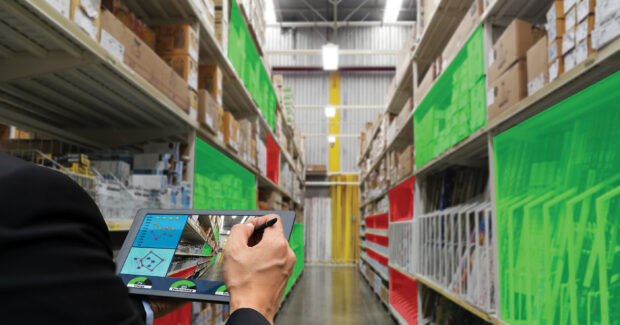

But when manufacturers connect to a variety of solutions, they can transcend these disruptions and focus on what they do best: metalworking. This month’s cover story, “Embrace Disruption: The Supply Chain,” describes the tools to position your metalworking shop for future shocks by building a supply chain that can bend without breaking, noted Leigh Chesley, Chief Customer Officer for Longbow Advantage Inc.

Don’t Miss the Boat

Strategies to overcome challenges include Enterprise Resource Planning (ERP) platforms, digital transformations of the shop floor, and tapping into the increasing practice of reshoring and nearshoring of critical manufacturing activities. The data compiled from software platforms supports, for example, the successful launch of new product lines, and flags challenges to the supply chain so you can react.

The supply chain is not broken but it is ailing — a turnaround is on the way. Excess inventory is one factor in the country’s inflation scenario, noted David Latona, CEO and president of Tompkins Solutions in Raleigh, N.C. He believed both inventory and price points will come down. “The demand hasn’t really decreased. It will take a little longer than normal considering how high inflation is,” Latona said.

In addition to implementing solutions and resources to better manage the supply chain, manufacturers should also keep the lines of communication open with suppliers to ensure visibility and transparency of the supply chain, noted Matthew Gordon-Box, product manager of supply chain at SYSPRO, located in Tustin, Calif.

Metalworkers can also use to their advantage the trend in the increase in the number of manufacturers returning critical production functions back to or near the U.S. marketplace. According to the Reshoring Initiative’s figures for 2022, the announced reshoring of jobs and FDI jobs to the United States increased 53% from 2021’s numbers, to 364,000 reshoring and FDI jobs.

Suppliers with operations in Mexico and Canada lower the transit time of products to three days or four days, as compared to transit times of 20 days for products coming from Southeast Asia. “They are the new ‘offshore’ manufacturing facilities,” Latona said.

A supply chain comprised of a diverse number of elements ensures the agility and resiliency of your logistics process. “Keep talking and keep your suppliers near,” Gordon-Box advised, to ensure a level of buffering in your manufacturing process.

www.fabricatingandmetalworking.com

Subscribe to learn the latest in manufacturing.