Advancements in Tube and Pipe Machinery Result in Speedy and Flexible Fabrication

Variations in machinery allow users to create unique designs and applications to support the emerging small tube segment.

Posted: April 19, 2023

Whether you are producing components for the agricultural, fitness, automotive, construction or other industries — even the furniture industry — these laser cutting machines can handle your specialized designs, from the smallest tubes to thick walls. Advances such as thread inserter units, and high feed rates that can handle even the smallest contours, as well as increased automation in the machines, ensure quick setups and efficient workflow. No matter how large or small the project.

New Thread Inserter Unit for Laser Tube Machine

BLM Group’s (Novi, MI) LT7 lasertube with 5 kW laser power offers a new thread inserter unit, which automatically installs thread inserts into laser cut/drilled holes using press fitting. A simple and widely relied upon joining technique, press fitting relies upon force and friction to hold two components together. A patent-pending technology exclusive to BLM GROUP, this inserter unit simplifies and shortens the processing time required for mating an insert with a tubular component.

The thread inserter is an ideal solution for thin wall tubes, which are not sufficient for standard threads, and an ideal partner with the LT7 machine. The system is capable of handling threaded hexagonal inserts from M4-to-M12 with automatic checks to ensure proper insertion. Post-laser cutting, the time to install inserts is only nine to 11 seconds per insert.

The LT7 tube cutting laser system is capable of handling tubes from 0.5”-to-6”, and up to 15.4 lbs./ft., and is available with either a 3 kW, 4 kW or 5 kW fiber laser. It features a 3D tilt cutting head and can perform high-precision angular cuts in round, square, triangular and special shapes. It also offers automated changeover for maximum productivity. At the end of each batch, the loader, spindle, steady rest and intermediate supports automatically adapt to the new section to be cut without any interruption of the production cycle. BLM Group’s Artube software makes for easy offline programming accommodation for the insertion process inside the same software for all other part programming.

Fast, Flexible and Affordable Tube Laser Processing

The Bystronic Inc. (Hoffman Estates, IL) ByTube Star 130 with 2 kW, 3 kW and new 4 kW fiber power, delivers tube laser processing for a variety of material types in a fully automated workflow. The ByTube Star 130 features a fiber laser cutting system that offers fabricators and manufacturers an entry-level machine into tube processing, a growing manufacturing market.

The applications for tubes are diverse: from automotive and construction to furniture, machine, and equipment manufacturing. The ByTube Star 130 provides a solution for sheet metal processing companies that want to expand their capabilities. The automated system reduces the need for manual interventions, simplifying entry into the field of tube processing.

Since 85% of the market potential lies in the small tube segment, the ByTube Star 130 is designed for processing tube profiles with dimensions between 3/8”-to-5” and workpiece lengths up to 28’ and a capacity of 11 lbs./ft. Tube profiles include round, square, rectangular, oval, standard closed and open sections. Since 2D cutting accounts for 90% of the market, the 2D cutting head can process a large number of customer orders.

Bystronic’s ByVision Tube user interface is highly intuitive. Even entry-level users without extensive experience can immediately operate the ByTube Star 130. Cutting jobs are set up quickly, and whether small series or large orders, users can move from the incoming order to the delivery of the finished parts in a quick and efficient workflow.

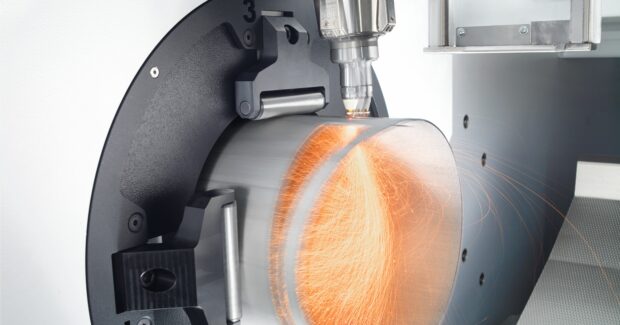

Maximum Tube Productivity Due to Machine’s Solid-state Laser — Even in XXL

With TRUMPF’s (Farmington, CT) TruLaser Tube 7000 fiber, the solid-state laser has a broad processing spectrum, and represents fast and flexible processing. Due to RapidCut, the high feed rates of the laser come into their own even on smaller contours. This is a significant productivity advantage, particularly in thinner materials. The open machine concept gives the TruLaser Tube 7000 fiber optimal accessibility during loading and unloading. This means the machine is efficient from a lot size of 1. Due to the Central Link interface, the machine is also optimally equipped for Industry 4.0.

Applications for the TruLaser Tube 7000 fiber include furniture, where the machine cuts tubes and profiles with great precision, which enables the production of the highest quality products. Whether it is for single-unit or series production, laser tube cutting also guarantees maximum flexibility for the design of shop furniture. The machine can also process thick walls, which is an advantage for the manufacture of components for agricultural machinery. The automation solutions of the machine allow for efficient production of high-quality components such as fitness equipment, where the laser provides long-lasting precision for tube processing. With this machine, mechanical and apparatus engineers can creatively replace or optimize sheet metal designs by combining tube and sheet metal construction techniques.

Among the features of the TruLaser Tube 7000 fiber:

- Process parts with a diameter of up to 10 in. and wall thicknesses of up to 0.4 in. for mild steel.

- Due to RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours, significantly reducing part times.

- The bevel cutting option enables high-quality bevel cuts of up to 45°.

- The TruDisk solid-state laser and high-quality cutting data produce the best possible results.

- The state-of-the-art sensor system ensures your entire machining process runs smoothly.

Subscribe to learn the latest in manufacturing.