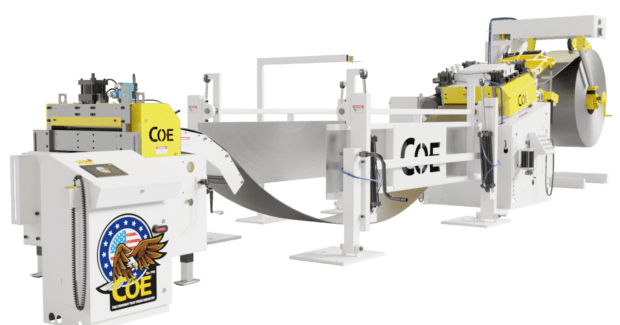

48-inch Coil Processing Line Installed at Eaton Corp.’s Highland, Ill., Facility

COE Press Equipment’s processing line is designed to handle MCRS at 45,000 PSI up to 0.100” thick in coil widths up to 34” or 0.050” when coil is 48” wide.

Posted: April 26, 2023

COE Press Equipment has recently shipped and installed a 48” coil processing line to the Highland, Ill. facility of Eaton Corporation, a leading manufacturer of quality support systems and enclosures for the mechanical, electrical and telecommunications industries. The line consists of COE’s 48” Series 4 Servo Roll Feed, 3.5” x 48” Power Straightener, a 15,000# x 48” capacity Coil Reel with Hydraulic Traveling Coil Car, and a 48” x 12’ Dual Threading Table. It also came with complete safety guarding.

The Eaton press feed system is designed to handle MCRS at 45,000 PSI up to 0.100” thick in coil widths up to 34” or 0.050” when coil is 48” wide. It can also process Stainless Steel in widths of up to 12” at 0.067” thickness. It can achieve a roll speed of 396 feet/minute with a feed accuracy of +/- 0.003”.

The line features Allen Bradley controls with COE’s IP Indexer capability, which automates many of the line functions, providing automatic expansion and drag brake control on the reel as well as recipe-driven passline height, Work Roll Advisor, linespeed averaging, laser loop control depth, lubrication control and coil centering.

COE also provided all installation, setup and training to this Eaton facility

About COE Press Equipment

COE Press Equipment designs and manufactures a complete line of premiere coil handling and servo roll feed equipment from stand-alone roll feeds, straighteners, reels, cradles and air feeds to complete integrated feed systems and cut-to-length lines. The company supplies and services a wide variety of global markets and industries including automotive, appliance, lighting, metal processing, housewares, lawn and garden, contract stampers, tool and die builders, and many others.

Facebook; Twitter; YouTube; LinkedIn

Subscribe to learn the latest in manufacturing.