WIKUS Saw Technology Corp.

Xceldyne, A Motorsports Component Manufacturer, Utilizes Wikus Band Saw Blades, Which Has Resulted

In 30% Longer Blade Life And Fewer Change Overs.

Posted: March 23, 2023

For Corey Smith, CEO of Xceldyne Group LLC in Thomasville, N.C., manufacturing high-performance titanium valves and valve train components in the heart of the North American motorsports industry has major benefits. The company works with its technical partners (customers) to solve their problems and ensure performance enhancement of Xceldyne’s parts. “Whether it is the endurance of a part, or horsepower gains,” Smith said. “It is all about the gains — what can the partner gain from our parts?”

Xceldyne’s sole market is the motorsports industry. Three of the four major NASCAR players are in Xceldyne’s region. Smith added the company provides products to just as many customers in the United Kingdom and western Europe as it does in North America. The company’s components service not only NASCAR but also the markets of Formula 1, NHRA, World Rally Championship, Endurance racing, IndyCar, Dirt Late Model racing and Sprint Car racing. “There is no major form of motorsports that we don’t have some footprint in,” Smith said.

Xceldyne supplies valve and valve train components to the motorsports industry, as well as rocker arms, lifters, spring retainers, spring locators, valve guides, and keepers, among others. The manufacturer also has a patented cam drive system product.

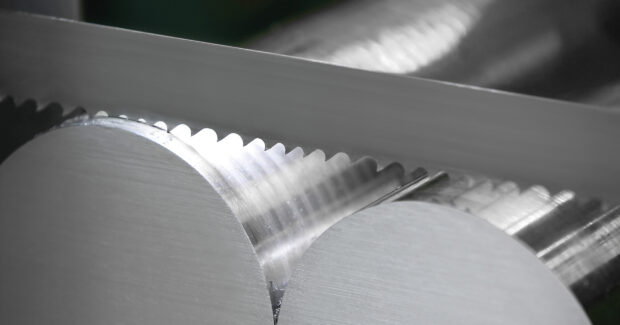

Smith said the company has experienced major growth the last few years, thanks to its focus on supplying to the motorsports industry. Xceldyne runs four saws at 110 hours per week. “Basically, we have 440 hours of saw time at this facility,” Smith said. The company uses band saw blades from WIKUS Saw Technology Corp. (Addison, IL) to assist in achieving its production goals. WIKUS is a world-leading band saw blade manufacturer. The company offers a wide range of band saw blades designed for specific customer applications.

Xceldyne utilizes WIKUS’ SELEKTA® GS X3000®, the MARATHON® X3000® and the MARATHON® M42 in its processes. Xceldyne uses the SELEKTA® GS X3000® for tool steels and nickel-based alloys. Benefits include a nearly 30% increase in blade life, as well as a much more improved finish compared to other blades. “Although it will be machined away, it makes the chucking on the parts nicer,” Smith noted. Another advantage is a nice squareness resulting from the cuts.

The MARATHON® X3000® is used for standard steels and titaniums, Smith noted, which also results in a nearly 30% increase in blade life.

Much like the approach with its technical partners (customers) in listening to their needs, spending the time to go back and forth to develop the products needed to accomplish the task at hand, the Xceldyne team also partners with WIKUS to ensure the best results. “Randy [Goss] has been a great help to us and has supported us with anything we need to improve our saw performance as best we can,” said James Cash, supervisor of valve train components for Xceldyne. Adds Smith: “I haven’t seen that type of support from a saw blade company before — and I have been doing this for more than 30 years.”

Goss, a service technician in WIKUS’ technical department, and his team regularly visit Xceldyne to inspect the saws and offer any type of support needed. “I think there is a lot of value add to using their products,” Smith added. That support goes a long way in assisting Xceldyne as it remains focused on serving the motorsports industry, remaining nimble to adapt to the changes in the industry and remain relevant to its technical partners.