Unique and New Tooling and Workholding Solutions Maximize Throughput

Product advances result in increased thermal barriers for higher rates of metal removal, and consistent and predictable tool life, as well as versatile product lines to handle a range of applications.

Posted: March 15, 2023

New Thread Cutting and Forming Taps Line Provides Versatility and Cost-Effective Solutions

Seco Tools LLC (Troy, MI) has expanded its range of tapping solutions with the launch of a new thread cutting and forming taps product line. The new versatile line encompasses three performance levels that allow manufacturers to cost-effectively match the right tap to their particular application. The combination of superior base materials, advanced coatings and special edge preparations mean that these Seco taps generate precision threads while they provide excellent chip evacuation, shorter setup times and longer tool life.

The three performance levels encompass the product designations of T32 and T34 in thread cutting taps and T33 in forming taps. At the base level are universal general-purpose type taps. The second T34 mid-level range consists of higher performance taps that work well in a variety of workpiece materials, making them especially well-suited for high-mix/low-volume production environments with constantly changing parts and materials. The top performance level is material-specific thread cutting and forming taps such as those optimized for steel or other advanced materials.

The main benefits of matching the right tap to the application include extended tool life that is consistent and predictable to reduce the risk of unexpected tap breakage and scrapping parts after hours of machining have been invested. Additionally, a range of tap performance levels ensures manufacturers only pay for the level of tap performance they actually need. For those shops with lower power machines or that don’t require material specific taps, the basic level is a versatile and cost-effective solution that helps them reduce the number of taps they need to keep in stock and lower their tooling inventory costs.

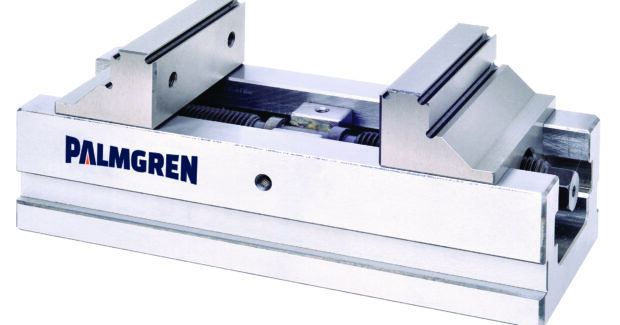

Dual Force Precision 5-Axis Vise Comes with a Selection of Jaw Styles

The Palmgren (Naperville, IL) 5-Axis Machining Vise is designed for multi-face machining of simple to complex workpieces. Although its space saving construction occupies less work room, the vise, with an easy clamping operation, has a large holding capacity to handle five-sided machining. A reduced amount of interference provides unrestricted all-around access to the workpiece. The #9625943 vise comes with a selection of jaw styles that will handle a wide variety of workpieces. The vise features Palmgren’s Dual Force anti-lift mechanism to counter the lifting effect on a part being machined.

New Sizes Added to T3 Thread Mill Line

Allied Machine & Engineering (Dover, OH), a leading manufacturer of holemaking and finishing cutting tools for the metal-cutting industry, announces the addition of new sizes to the AccuThread T3 thread mill line. Because of the success of the current line and customer demand for larger sizes, the AccuThread T3 is now available in larger UN and ISO sizes up to 1”-8 and M24x3.0. Machine coding for the new sizes is included in Insta-Code, Allied Machine’s online thread mill program generator.

Targeting high-production facilities, tool and die industries and high-temperature applications, the additional AccuThread T3 thread mill sizes create a high-quality thread without the concern of breaking a tool in an expensive workpiece. It is designed to only machine three threads at a time, which reduces tool pressure and dramatically increases the chances of tool survival.

Leading Tooling Company Fulfils Customer Demand with New In-Stock Products

To ensure customers receive the tooling they need as quickly as possible, CERATIZIT USA (Schaumburg, IL) offers three advanced tooling solutions that are in-stock and ready for immediate delivery. These innovative solutions include enhancements to the EcoCut Series of indexable inserts, the new PolyClamp Verso universal part clamping system, and the new MaxiLock-N turning toolholders that incorporate the company’s DirectCooling technology.

To overcome the challenges of turning and drilling steels, CERATIZIT has updated its classic EcoCut to the new EcoCut-P, and extensive tests have shown that the new inserts achieve 15% greater performance than the predecessor models. With the company’s special DRAGONSKIN coating for ISO-P materials, the inserts increase tool life and reduce machining time — thanks to the coating’s optimized layer structure. The coating’s mechanical post-treatment induces a unique state of residual stress in the layer surface, which in turn increases process security; the coating is particularly well suited for when uninterrupted cuts are required.

Featuring universal multiple vises, the PolyClamp Verso from CERATIZIT is ideal for use in 3-, 4- or 5-axis machines, where it easily clamps all part variants. The system’s jaws are slimmed down for this purpose while allowing even more jaws to be clamped per base rail for clamping larger unmachined or finished parts. The system is equipped with a quick jaw change system as standard. Using just two screws, the fixed and adjustable jaws are released, removed upwards or repositioned. Each jaw can be removed individually without dismantling the others.

A scale lasered onto the centric vise is a further benefit when it comes to handling, which allows the jaws to be positioned evenly and precisely on the rail, in accordance with requirements.

Complementing CERATIZIT’s DirectCooling product range, the MaxiLock-N turning tool holders incorporate two internal coolant holes that aim coolant directly at the cutting edge to prevent wear and ensure stable processes. Using these coolant holes, nozzles direct coolant to the clamping flat from above as well as from below to the flank. This additional flank cooling contributes to the tool’s ability to extend tool life by 60% compared to those that cool only at the clamping flat.

To avoid interference with workpiece contours, the lengths of DirectCooling Series holders are ideally matched to one another and offer optimal stability and unlimited flexibility. What’s more, an HSK-T universal standard interface for turning tools ensures straightforward connection to multifunction machines such as turning/milling centers and milling/turning centers.

www.CuttingTools.CERATIZIT.com

New Unique, High Productivity “PunchDrill” Offers Time Savings

EMUGE-FRANKEN USA (West Boylston, MA), a leading manufacturer of high-performance taps, thread mills, end mills, drills, and other rotary tools, has announced the PunchDrill. It is a totally new drill design offering high feed drilling which doubles the feed rate compared to standard drills without increasing the axial force or spindle speed. PunchDrill reduces machining forces and optimizes chip breaking, producing cycle time savings of 50% or more when machining cast aluminum alloys with at least 7% Si content and magnesium alloys.

The PunchDrill features patent-pending geometry with an innovative chip breaker which produces short chips to control machining forces. The new drill also has newly developed surface treatments and a hard diamond-like coating specially designed for this application to provide reliable chip removal and increased process reliability. When the high-speed PunchDrill is used at the recommended feed and speed, axial force is reduced by half. The increase of the feed at the same rotational speed results in a significant decrease of machining time with less machine wear, while retaining tool life. The self-centering capability of the drill tip enables the best possible positioning accuracy on holes.

The PunchDrill is available in drilling depth ranges up to approximately 8 x D, the nominal diameter range from 0.129″-to-0.472″ (3.3 mm-to-12 mm). Machining is done with a normal drilling cycle on CNC machines with cutting speeds and coolant pressures similar to conventional drilling.

New Gold Standard Turning Insert Grade with Advanced Coating Technology

Kennametal Inc. (Pittsburgh, PA), a leader in metal-cutting tools and solutions, has introduced a new, higher performance turning grade with an advanced coating technology. KCP25C with KENGold™ is the first choice for metal-cutting inserts with improved wear and higher metal removal rates for steel-turning applications.

“Our high performance KCP25C grade inserts with KENGold coating technology set a new standard for machinists working across a variety of steel turning applications,” said Kennametal Vice President of Global Product Management Scott Etling. “This gold standard turning insert delivers a one-two performance punch of higher metal removal rates and improved wear resistance, meaning our customers can machine longer and with greater productivity and efficiency than before. Additionally, the insert’s gold flank makes it easy to visually identify wear, maximize edge use and reduce waste.”

KCP25C is the first-choice carbide grade for turning inserts in general purpose applications in a variety of steel materials and delivers consistent, repeatable performance. KENGold is a proprietary, multi-layer coating technology with enhanced pre- and post-coat processes that deliver an effective thermal barrier for greater crater wear resistance, typically experienced in these types of machining applications.

The KCP25C with KENGold is available in C, D, S, T, V and W.

Platinum Tooling is the Official Importer of Rineck Shrink Fit Technology

Platinum Tooling Technologies, Inc. (Prospect Heights, IL) an importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, is now the importer of Rineck shrink fit tooling and shrink fit machine technology in the United States and Mexico.

Rineck offers standard and custom shrink fit tool holders with various connections including CAT, HSK, BT, SK, PSC and straight shank extensions. In addition, ER shrink fit collets are available. For added rigidity, flange or dual contact holders are available for CAT and BT tapers. A clamping range from 3-to-32 mm is possible for both slim and standard styles. All tools are available in inch and metric sizes.

Rineck produces a wide range of standard shrink fit tool holders as well as custom tooling. In addition to standard 4.5° taper tools, 3° slim and extra slim tools are available. Most holders come standard with length adjusting screws. Coolant delivery to the cutting tool can be achieved either through the center or flange of the tool holder utilizing coolant jets or slots.

In addition to shrink fit tool holders, Platinum Tooling will offer shrink fit machine technology. Equipped with an elevation cooling system, heated tools can be moved to a cooling tank with a push of a button. The machine’s smart design keeps accessories stored but close at hand during operation.

Ceramic Exchangeable Milling Heads Take the Heat in HRSA Machining

With aerospace components manufactured from nickel-based alloys becoming increasingly prevalent, the demand for optimized cutting tools is growing. With this in mind, Sandvik Coromant (Mebane, N.C.) has developed two innovative solutions ideal for shoulder and face milling of nickel alloy aero-engine parts.

“The ceramic substrate of the latest CoroMill® 316 allows for a different cutting process than traditional solid carbide tools,” explained Sandvik Coromant’s Global Offer Manager, Solid End Mills, Tiziana Pro. “Our unique S1KU grade is purpose designed for the superior machining of nickel alloys and is supported by a negative geometry that offers a tough cutting edge.

“In fact, the six-flute geometry delivers highly productive side milling operations, while the four-flute geometry boosts face milling,” Pro continued. “The CoroMill 316 is a perfect tool for difficult-to-reach applications or if you are looking for extra flexibility, thanks to the exchangeable head system.”

Ceramic tools retain their hardness at the high temperatures associated with milling heat-resistant super alloys (HRSAs). As a result, 20-to-30 times the speed can be achieved compared to solid carbide tools, delivering considerable potential for increased productivity. With the new, bigger head diameter available from D16-25 mm, it will be possible to reach these high cutting speeds with conventional machining centers (n = 10,000-to-18,000 rpm).

Beyond shoulder and face milling, the new end mills can also be used for pocket milling, helical interpolation, ramping and slot milling.

Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry.

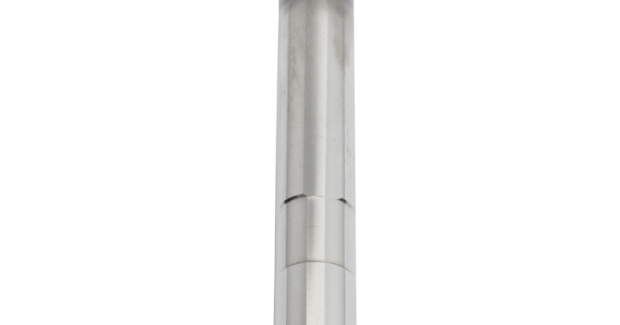

Double Contour Single Flute Gundrill with Extended Carbide Head Capability

Star SU LLC (Hoffman Estates, IL), part of the Star Cutter family of companies, has announced its new custom-designed Double Contour Single Flute Gundrill with an extended carbide length head feature. This special tool design has proven to reduce tool drift for the length of the cut, providing excellent TIR readings from entry of the part to the exit.

The machining improvements are achieved by a special cutting drill contour with an added rear contour configuration that acts like a guide pad while the drill remains in the bushing, keeping the tool on location. Once the drill is in the cut, these guide pads continue to force the tool to cut a straight path for the remainder of operation.

In a case study involving the machining of 36.0” DOC holes in Ti6AL4V (Titanium Grade 5), with the part being drilled from both sides and the hole meeting in the middle, the special-design Star SU Double Contour Single Flute Gundrill achieved an average mismatch at the intersection of only .005” and average drift/inch of .00003”, as compared to .036” mismatch and .0020” drift achieved by a standard single flute gundrill. In addition to titanium, these drills are also successful in machining cast iron, aluminum, stainless steel, Inconel, and 4140/4150V steels.

Next Technology High Feed Indexable Milling Platform

Dapra Corp. (Bloomfield, CT) announces DAPRA Next Technology VAPOR™ powered by TRI-X2.

The VAPOR high feed indexable milling platform has unique elements in body design and TRI-X2 insert geometry for higher metal removal rates and extended tool life. VAPOR is ideal for extreme machining with modern machine tool technology. It utilizes light depth of cut combined with extreme feed per tooth to increase productivity.

Benefits include versatility through positive cutting geometry and excellent ramping capability. The initial offering is a double-sided 6 mm insert series.

New, Versatile 5-Flute End Mills

WIDIA™ (Latrobe, PA) has expanded the capabilities of its bestselling WCE solid end milling series with a 5-flute geometry specifically designed for optimal performance when shoulder milling and side milling carbon, stainless steel and cast iron. The WCE5 solid end mill combines the unequal index feature with an elevated 38° helix to deliver unparalleled machining performance.

The 5-flute square-end end mill with sharp edges, chamfers and corner radii joins a 4-flute square-end and ball-nose end mill with both straight and Weldon® shanks as part of WIDIA’s WCE solid end mill portfolio. The WCE4, a 4-flute geometry solid end mill, combines the asymmetrical index and variable helix features to excel in operations like full slots and heavy cuts.

Both the WCE4 and WCE5 solid end mill series are available in inch and metric measurement systems.

Subscribe to learn the latest in manufacturing.