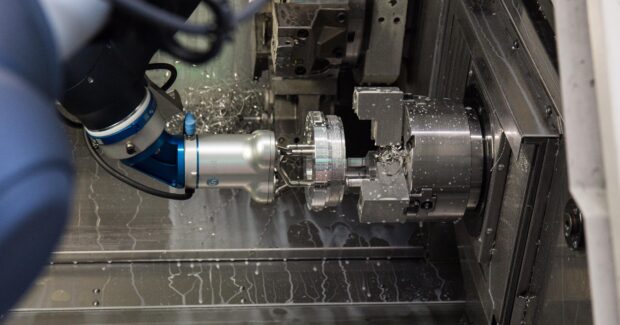

Safely Conduct Machine Tending Processes with Cobots Suited for Shops of all Sizes

Robotic and automated machine tending and material handling systems add autonomy and flexibility to your operations.

Posted: March 15, 2023

Orbital Wrapper Company Enlarges Standard Sizes to Assist Large Pallet Loads

Orbital wrapping manufacturer TAB Industries, LLC (Reading, PA) has enlarged the standard sizes of its TAB Wrapper Tornado orbital wrappers. Upgraded to meet customer demand for increasingly larger pallet loads across all industries, the new standard size orbital stretch wrapper models feature a choice of 80“, 100“, and 115“ wrapping rings to accommodate a wide range of parts and products on 48”-x-48” and 60”-x-60” pallets, and on 50” wide pallet loads as tall as nearly eight feet, respectively. The 115“ TAB Wrapper Tornado once held the record as the company‘s largest orbital wrapping machine when manufactured as a custom solution.

Maintaining the slim profile of 57“ deep, the three wrapper sizes are offered on the semi-automated TAB Wrapper Tornado Standard, the automated TAB Wrapper Tornado Smart Controls models, and the fully automated TAB Wrapper Tornado Perfect Storm. The 40-inch orbital wrapper machine that suits 24”-x-24” pallets and the 50“ model are still available as custom orders.

The award-winning TAB Wrapper Tornado orbital wrapping machines wrap plastic film 360 degrees under and around the pallet and load to create a secure, unitized load that prevents shifting and sliding in transit. The stretch wrapping machines are designed and manufactured at the company‘s Reading headquarters and delivered ready for operation, with a warranty.

Fight Labor Shortages with Fast and Flexible Cobot Deployments

Rapid Robotics (San Francisco, CA) entered a new partnership with Universal Robots (UR) (Odense, Denmark) in which UR will supply collaborative robot arms for Rapid Robotics’ deployment of cobot work cells across North America. As a proven manufacturer of high-quality, versatile robots, UR will enable Rapid Robotics to serve a greater number of customers and maintain the rapid deployment times they’ve come to expect even as Rapid Robotics continues to expand its national footprint.

“As the number of unfilled, critical manufacturing roles increases and global economic uncertainty continues to impact supply chains, more and more North American manufacturers are turning to automation,” said Jordan Kretchmer, CEO and Co-Founder of Rapid Robotics. “This collaboration with UR helps us deploy more cobots, with a wider variety of capabilities, at a faster rate, ultimately helping manufacturers of all shapes and sizes manage and even thrive through the adversity they are facing.”

Rapid Robotics is integrated with and can deploy any cobot from the UR product portfolio, allowing for expansion in capabilities such as palletizing, box building and packing, and operations requiring a heavier payload or longer reach. Rapid Robotics will also have greater flexibility in the design of work cells and selection of peripheral equipment. Together, Rapid Robotics and UR also bring new levels of speed to cobot deployments. UR’s two-week ship program makes it one of the fastest in the industry and Rapid Robotics’ powerful mix of state-of-the-art AI, advanced vision systems and unique software stack means robots can be up and running in customer facilities in a matter of weeks versus the typical months to years.

“Universal Robots has spent the last decade in North America focused on freeing up more manpower by automating a wide range of human-scale tasks with easy-to-deploy cobots,” said Bryan Bird, Universal Robots’ regional sales president. “We’re excited to work with Rapid Robotics in a partnership that will enable us to break down more automation barriers, deploying a robotic workforce to address those jobs manufacturers simply can’t staff.”

Small Footprint, Modular and Easy to use Machine Tool Tending Cell

ABB Robotics’ (Auburn Hills, MI) FlexLoader™ SC 3000 is setting new standards in flexible machine tool tending. This standardized solution increases machine tool utilization by as much as 60% while reducing operating costs. The key characteristics of this model are its modularity (users can customize the robot cell to meet any need), small footprint and ease of use. The FlexLoader comes complete with a fully integrated robot with a pre-programmed robot code for a short installation time.

The FlexLoader SC 3000 machine tool tending cell is ABB’s next generation of compact machine tool tending cells and includes a 6-axis robot ideally suited to the reach and payload requirements of the specific application. FlexLoader SC 3000‘s are ideal for both low and high-volume production, tending vertical lathes, horizontal and vertical machining centers, 5-axis machines and grinders.

The FlexLoader comes with FlexLoader Vision, which provides the flexibility to automate the machine tending of parts that range from small to very large. It is specifically designed for robot guidance and has a simple and intuitive workpiece teach-in process. The internal buffering system allows the machine to run free from operator supervision for hours, depending on the workpiece size and cycle time.

Machine Tending Cell Suited for Small and Medium-sized Shops

In answer to the ongoing lack of skilled labor, KUKA Robotics (Shelby Township, MI) showcased at IMTS 2022 a Waybo (Mirabel, Quebec, Canada) machine tending cell called the PartNR featuring a KUKA AGILUS robot as a solution. KR AGILUS is a compact six-axis robot that is designed for particularly high working speeds.

The Waybo series of pre-engineered compact machine tending cells are well suited for small and medium job shops that want to automate CNC machines for high-mix/low-volume manufacturing applications. These compact cells are easy to install, can be moved from one machine tool to another and are simple to set up for the next batch of products. Because they can run autonomously for many hours they offer a quick return on investment.

The PartNR machine tending cell combine the high speed and compact design of the KR AGILUS with a variety of feeding mechanisms. The cells handle payloads up to 10 kg, while the CyberDrawers turnkey machine loading system combines the higher 20 kg payload and reach of the KR CYBERTECH, with the high capacity and flexibility of the drawers feeding system. It is ideal for automating lathes, and the easy to use interface eliminates the need for programming.

Flexible, Large Stroke 3-Finger Gripper

OnRobot’s (Dallas, Texas) 3FG15 is ideal for gripping a wide range of cylindrical objects in machine-tending applications such as CNC lathe machines. The gripper’s design automatically centers workpieces, resulting in fast deployment with a strong, stable grip and precise placement. With a payload of up to 15 kg, and gripping force from 10 N to 240 N, the 3FG15 competes with larger, bulkier, and much less flexible finger grippers. Like all OnRobot grippers, the 3FG15 offers seamless integration with the robots of your choice.

The 3FG15 three-finger gripper has an impressive maximum stroke of 150 mm and a sleek design that can easily handle multiple processes. It is ideal for gripping a wide range of cylindrical objects from 20-to-150 mm wide in machine-tending applications such as CNC lathe machines, insertion applications, and even palletizing. The 3FG15 provides a strong, stable grip for both form fit (inside the object) or friction fit (external) gripping, adding flexibility to your implementation.

Elevating Worker Platforms Vertically Position Employees

Elevating Worker Platform Lifts from Presto ECOA (Norton, MA) are the perfect solution for assembly, repair or maintenance of large or tall workpieces, such as transportation equipment (trucks, buses, aircraft, etc.); electrical sub-assemblies; or any other large, awkward shaped items that must be accessed at elevated or varying heights. Not only do they position workers at a comfortable, convenient height, they also provide a stable platform with room for multiple workers, tools, workstations, test equipment, computers, and so on. They are safer, more comfortable, and versatile than ladders or scaffolding. Platform height can be quickly and easily adjusted at the touch of a button.

Fully customizable to the application, the platform lifts can be configured with a variety of options including custom platform shapes/cutouts; slide out decks and bridges; anti-skid or anti-static deck coatings; redundant controls; soft start/stop; indexed lifting and lowering; powered traverse; bellows skirting that keeps dust, debris, and moisture out of the lift mechanism; and many more.

Subscribe to learn the latest in manufacturing.