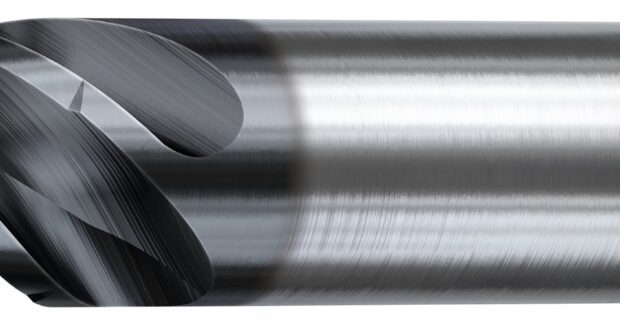

Heavy-duty Solid End Milling with Superior Performance

New grades for Sandvik Coromant’s CoroMill® Plura HD increase productivity without compromising tool life or process security.

Posted: March 22, 2023

Cutting tool specialist Sandvik Coromant is expanding its offering of CoroMill® Plura HD solid end mills for heavy-duty roughing in steel and stainless steel with two new grades. This new generation of grades features the unique Zertivo™ 2.0 coating, which combines world-class productivity with an exceptional metal removal rate and the highest possible process security.

CoroMill Plura HD is Sandvik Coromant’s first-choice optimized solution for heavy-duty applications up to 2×D in steel and stainless steel (ISO P and ISO M), offering safe and efficient solid end milling. The new Zertivo 2.0-coated grade further improves tool life, process security and productivity.

“With Zertivo 2.0, we are applying our comprehensive knowledge in coating technologies to our solid round tools,” says Antti Wikström, Global Product Manager, Solid End Mills, at Sandvik Coromant. “This gives us an opportunity to offer unique, custom-made coatings that can handle our customers’ machining challenges with superior performance and tooling efficiency.”

The new grades enable a 30 percent increase in cutting speed recommendations for the primary ISO P and ISO M application areas, as well as secondary ISO K and ISO S materials, thanks to their optimized flute shape, which offers effective chip evacuation. The grades designed for stainless steel machining come in two variants: one with internal coolant for improved temperature control and chip flow, and one without internal coolant.

The standard assortment offers diameters from 2–25 mm, a 2×D depth of cut, 4 to 5 teeth and a ramping angle of 5° or 7°. Tailor Made® options are available within the Customized Solutions range.

Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 1,700 patents worldwide, employs over 7,700 staff, and is represented in 150 countries.

www.sandvik.coromant.com

Subscribe to learn the latest in manufacturing.