Transformative, Precise and Fast-moving Cutting Systems Expand Opportunities

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

Posted: February 16, 2023

Major technological gains in the development of cutting systems, such as double the kilowatts in some laser cutting systems, as well as a wide range of machine levels and power levels to select from, ensures laser, plasma, waterjet and oxyfuel cutting systems deliver newfound levels of performance. These reliable, flexible and precise systems result in higher levels of productivity for fabricators.

Affordable, Entry-Level Laser Cutter has Features of High-End System

BLM GROUP’s (Novi, MI) LS7 sheet laser cutting machine is a brand-new addition to its line-up resulting from the company’s most current technological research. The LS7 was designed as an entry-level product in the high-end system segment, i.e., a product with all the features and functionality of a high-end system, but at an attractive price.

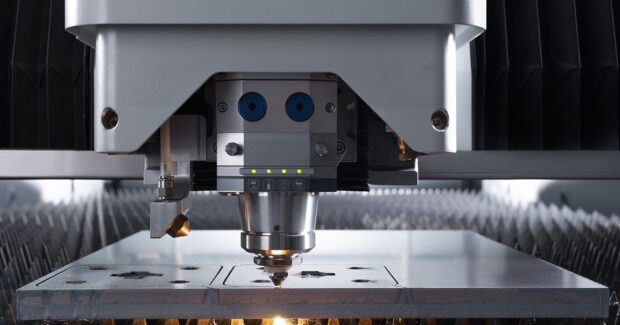

The LS7 has a conventional aluminum mobile gantry structure actuated by a rack and pinion system, which slides on a steel base filled with a special polymer to ensure high rigidity even with high accelerations up to 2g. The pallet change can be accomplished in only nine seconds, taking place on the long side of the machine. This speed is attainable thanks to a smart mechanical solution that anticipates the simultaneous exchange of the two tables. Handling is fully electric, without pneumatic or hydraulic actuators, for improved maintenance and energy usage. These features, in combination with the ability to use laser power up to 12kW, makes the LS7 a highly productive machine.

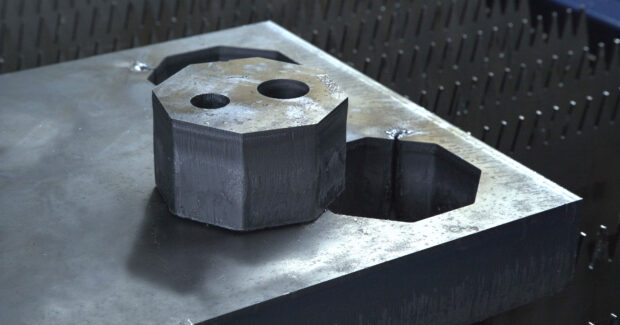

The LS7 can cut steel, stainless steel, iron, copper, brass, and aluminum in thicknesses from 0.20-to-1.57”, or even double sheets, depending upon the material and selected laser power. It is available in two versions – the 3015 with a maximum sheet size of 121.5”-x-62.2” and the 4020, capable of handling sheet sizes up to 162.5″-x-79.5″.

Users can add automatic sheet loading and unloading with one or two storage towers for automated material type and thickness changeovers, which is especially well-suited for unmanned operations.

Another feature of the LS7 include plug and play operations that leads to fast and easy equipment setup, ability to integrate with ERP systems, as well as material handling and storage systems, leading to better interconnectivity. The system also comes equipped with the company’s patented Active Tools, which automatically adapt process parameters for optimal results independent of operator experience, ensuring the highest cutting precision and speed.

Thermal Dynamics® Automation Upgrades and Rebrands Plasma Cutting Systems

Thermal Dynamics Automation’s (Denton, TX) new UC Series of high-precision automated plasma sources, an updated version of its Ultra-Cut® XT systems, features a modernized inverter block with state-of-the-art power switching components, a new cabinet design with an LED strip for an at-a-glance assessment of machine status. The UC Series features four models, all rated at 100% duty cycle: the UC 131 (130A), UC 201 (200A), UC 301 (300A) and UC 401 (400A).

“Over the last two years, we made so many incremental improvements to cut faster, better and smarter that it warranted rebranding our high-precision automated plasma systems as the UC Series,” said Dirk Ott, VP – Global Plasma Automation for Thermal Dynamics. “For example, two UC 201, UC 301 or UC 401 can now be connected double cutting output to 400, 600 or 800 amps, respectively, or they can operate independently.”

Target applications for this new capability, which is similar to paralleling welders, include fabricators and steel services centers that use two torches on the same gantry and want to increase cutting speeds on steel plates up to 2 in. (50 mm) thick. It also allows fabricators to cut stainless steel and aluminum sections up to 6.25 in. (160 mm) for applications in the power generation, pressure vessel, chemical and petrochemical processing industries. To double a torch’s cutting output, users need to change the SpeedLok™ consumables cartridge, which takes less than a minute.

“This new capability features modest software and hardware enhancements, but the challenge was developing the new 600A and 800A consumables for stainless steel and aluminum that fit into the same footprint as our existing SpeedLok consumables,” Ott said.

The UC 131 features new consumables and is optimized for piercing and cutting 3/4 in. (20 mm) steel, stainless and aluminum. It covers the majority of high precision cutting applications at an aggressive price point, and it offers a good retrofit opportunity for older 100A systems. Compared to the previous Ultra-Cut 100 XT, it offers 30% more power, 20% faster cutting speed and 50% longer parts life when cutting at 130A on mild steel. The UC 131 cuts 3/4 in. steel at 52 IPM (20 mm at 1321 mm/min) and 1/2 in. steel at 85 IPM (12 mm at 2159 mm/min).

The Future of Large Format Laser Cutting

The all-new Messer Cutting Systems (Menomonee Falls, WI) Element 400L unitized cutting machine is the embodiment of the company’s new platform solution, drawing from 120 years of experience in thermal cutting. It’s a highly flexible all-around laser cutting machine that promotes safety, efficiency, and automation versatility and its hardware and software are upgradeable from a single source. The Element is equipped for all common cutting and additional processes, for both continuous operation and special tasks, with a focus on precision-cut parts and fast traverse speeds.

This machine is the future of large-format laser cutting up to 20kW. It supports plasma and laser beveling, including marking. The U.S.-manufactured cutting machine has acceleration and speeds that can support two laser or plasma heads with no loss of performance. Also joining the Element 400L unitized will be the all-new Bevel-U. This high-precision bevel unit supports laser beveling up to plus/minus 52°. The higher acceleration of the new Element 400L will provide a better cut quality with vertical or bevel cutting surpassing any of the competition. On board the Element L is the Slagger® self-cleaning table.

The Element 400L, coupled with material handling solutions and OmniFab Software, is tailor-made for order-related production. It integrates Messer’s mechanical engineering technology into the daily business process which makes it possible to achieve complete end-to-end integration from the front office to the finished goods.

Fast, Reliable and Affordable Laser Cutting

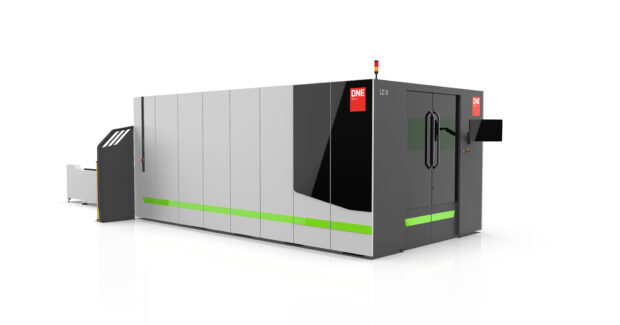

DNE Global’s (Hoffman Estates, IL) LC 3 fiber laser cutting machine combines efficiency, speed, and ease of operation, with state-of-the-art laser cutting technology and Swiss engineering, to deliver the performance to succeed in sheet metal cutting.

DNE Global’s LC 3 is a fast and reliable laser cutting machine that ensures more profit per part. Other benefits include:

- Local service support and parts availability – fast response time, proven components

- Attractive price-performance ratio

- State-of-the-art technology based on Swiss expertise

- Set a benchmark in terms of programming

- Maximum operating convenience

- Powerful laser output of up to 6 kilowatts

Unprecedented LBC Technology Cuts up to Three Times Faster Than Conventional Fiber Lasers

AMADA AMERICA, INC.’s (Buena Park, CA) VENTIS 3015 AJe 6kW fiber laser cutting system with Locus Beam Control (LBC) technology outperforms higher wattage fiber lasers at a considerably lower operating cost. VENTIS utilizes AMADA’s revolutionary LBC to achieve infinite locus patterns — ensuring optimum beam shape control for each specific cutting application. LBC technology delivers unprecedented high-speed and high-quality cutting up to three times faster than a conventional fiber laser. A high-brightness fiber laser oscillator maintains optimal quality of the high-energy density laser beam. As a result, VENTIS provides virtually dross-free cutting of a variety of materials and thicknesses including stainless steel and aluminum.

Features include:

- Productivity Mode: In the N2 non-oxidizing cutting of medium-thick stainless steel and aluminum, processing cost can be reduced by up to 75%.

- Quality Mode: Cut quality is ensured by reducing the surface roughness by approximately 50% when compared to a conventional machine and dross is reduced to less than 10 μm.

- Kerf Control Mode: Enables long-term stable processing during automated system operation. By oscillating the beam, the kerf width can be controlled to 2.5 times wider than a conventional machine.

The high cutting speed, reduced power consumption, and other process parameters mean that the costs of operating the 6kW VENTIS are considerably lower than a system with a higher output level.

New, Affordable All-In-One Robotic Plasma Cutting Machine

With stairs, rails, ladders, and more, fabricators have challenges that require automation. HGG Profiling Equipment’s (Houston, TX) RoboRail offers the fabricator an affordable, versatile, and powerful solution that replaces many traditional machines. It’s the first small robotic plasma machine that cuts 12” channel, tube columns and angles up to 8”-x-8”, and 1-1/4″-to-10” pipe. By taking care of so much miscellaneous work, and supplementing larger capacity machines with added flexibility, RoboRail is the new fab shop workhorse. RoboRail is represented exclusively in North America by Automated Layout Technology.

HGG’s RoboRail incorporates advanced robotic technology to process a vast range of materials quickly and accurately to length, making cuts, holes, copes, while performing layout marking. Handrail pipe, stringer channels, box tubes, angles and more are all processed with robotic efficiency, using a reliable Hypertherm plasma system.

RoboRail accepts files directly from SDS/2, TEKLA, STEP, and various other modeling software to automate the cutting process, dramatically reducing process times while eliminating human error and fabricators’ reliance on skilled employees.

RoboRail is also a powerful tool for larger structural and industrial fabricators. It can also cut tube columns and angles up to 8″-x- 8″ and channels up to 12”.

24kW Laser Power Packs a Punch

TRUMPF Inc.’s (Farmington, CT) upgraded TruLaser 5000 series laser cutting machine is now outfitted with a laser providing twice the power that was formerly standard. With an output of 24kW, the new laser — a TruDisk 24001 — can process sheet-metal parts up to three times more quickly. Depending on the material and the application, the upgraded TruLaser 5000 can handle up to 80% more sheets of metal per hour.

“Increased laser power means companies can slash processing times while also improving the quality of processed parts,” said TRUMPF Inc. TruLaser Product Group Manager Salay Quaranta. “With its patented cutting unit, automated functions and dynamic performance, this technology significantly boosts productivity.” With double the laser power, the new machine can cut parts significantly faster. In addition, the more powerful TruLaser 5000 is able to cut mild steel with a sheet thickness of up to 3/4 of an inch using nitrogen as the cutting gas. “Imagine cutting stainless and mild steel over 1.5 inches, that opens up incredible possibilities,” Quaranta added.

With a 12kW laser, sheet-metal processors are able to cut sheets of mild steel to a maximum thickness of 9/16 of an inch when nitrogen is used as a cutting gas. To cut thicker parts, it is necessary to add oxygen. This leads to the formation of an oxide layer on the cut edges of the part. These must then be removed either by machine or by hand — a process that is laborious and time-consuming.

Alternatively, companies can use a plasma machine to cut thick parts. This, however, is much slower and less precise than a laser-cutting machine. By contrast, the 24kW machine can handle sheet thicknesses of up to 3/4 of an inch while using nitrogen. As a result, there is barely any need for reworking and productivity therefore increases. At the same time, the increased laser power improves the quality of cut parts, especially for medium and high sheet thicknesses.

Laser Cutting Machine Redefines High Performance Innovation

Bystronic Inc.’s (Hoffman Estates, IL) ByStar Fiber with 20kW Fiber offers speed, precision, flexibility and versatility. Thanks to the new laser output of 20kW, the ByStar Fiber cuts steel, aluminum, and stainless steel with a thickness from 20 gauge up to 1.500”, and brass and copper up to .750” with high precision. This power and increased range of materials enables sheet metal processing companies to further expand their production capabilities.

The technological leap from conventional 3kW to 15kW systems to the current 20kW level is tremendous. On average, thanks to the 20kW laser, the cutting speed of the ByStar Fiber increases by up to 50% (when cutting with nitrogen) compared to a 10kW laser source. Regardless of whether cutting aluminum, non-ferrous metals, or steel, the high-performance Bystronic SSC3 cutting head excels with precision in both thin and thick sheets and profiles. The variable telescoping cutting head automatically adjusts the focal length and spot size, and the focal position is set automatically for each material.

With the BeamShaper function, the beam profile is adapted for cutting thicker materials providing for smooth cutting edges and increased speeds in carbon steels from .750-to -1.125”.

Metal Processing Stations Improve Productivity on a Large Scale

Tecoi USA (Longview, TX) is internationally recognized for designing, developing, manufacturing, installing, and maintaining customized metal cutting and processing equipment for laser cutting, plasma and oxyfuel cutting, plate machining, and edge preparation for welding.

With its new headquarters in Longview, Texas, Tecoi USA can provide more comprehensive service and support for its growing customer base of metal processors in North America. It offers a full line of metal processing stations designed to improve productivity on a large scale. That includes large format and dimension laser cutting stations; large format oxyfuel and plasma plate cutting stations that also incorporate and combine machining functions such as beveling, milling, and drilling; equipment for automated plate storage; waste disposal equipment; fume extraction and noise reduction equipment; as well as cutting tables and manual and automatic tube lathes.

Tecoi USA metal processing stations incorporate advanced artificial intelligence. With collaborative cell technology users can assign jobs to the right machine on-the-fly, collaborate between several machines working on the same plate at the same time, and benefit from advanced material handling solutions for loading and unloading plates. Tecoi is one of the first companies to develop a 4.0 industry solution with full ERP connectivity.

Tecoi USA designs and manufactures customized solutions for a wide array of companies and industries that comprise a wide range of sectors in metal processing– including metal service centers, steel construction, heavy duty machinery, the oil and gas industry, shipyards, and for wind power.

Revolutionary Waterjet Delivers Optimum Productivity and Unmatched Service

Flow Waterjet Americas’ (Kent, WA) Mach 500 waterjet system, driven by extensive research and continuous customer feedback, is revolutionary for its throughput, reliability and ease of operation. The complete cutting solution is integrated with top-of-the-line components from world-leading suppliers for the machine drive, precision motion system, control, and solid model software to create the quickest, most accurate Flow waterjet system available.

The Mach 500 is uniquely configurable with options such as Dynamic Waterjet® XD for bevel cutting, 94,000 psi HyperJet® pump technology , and FlowXpert® software, for industry-leading performance and accuracy. Backed by exclusive FlowCare service programs, Flow’s Mach 500 delivers optimum productivity and unmatched service and ROI.

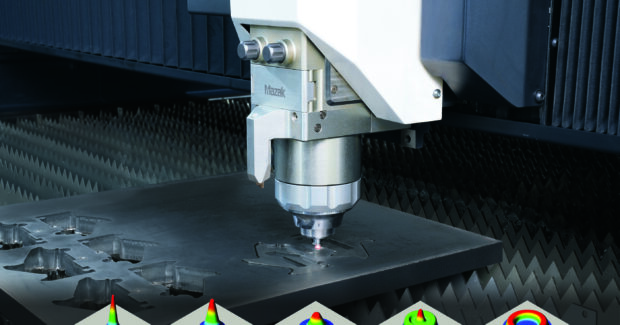

High Power and Maximum Control in a Range of Power Levels

Mazak Optonics Corp.’s (Elgin, IL) OPTIPLEX NEO is a flexible and highly efficient laser solution for all fabricating shops. It is now available in a range of power levels based on the customer’s needs.

NEO is equipped with technology that allows for increased beam shape and diameter control. The machine automatically adjusts the beam diameter to optimally cut various materials and the beam shape to control the concentration and power density of the laser beam. The result is improved cut speed and quality for a wide range of materials.

Equipped with large front and side access doors, the OPTIPLEX NEO offers accessibility and ease of operation. Minimized work area restrictions make loading material onto the machine and unloading finished parts easier.

The new MAZATROL SmoothLx CNC control features a large 21.5” screen and touch panel. Dual monitors allow multiple applications to run simultaneously. Additionally, the CNC control rotates, allowing operators the flexibility to work at the front or side of the machine.

Mazak’s OPTIPLEX NEO is equipped with a Nozzle Changer, Nozzle Centering Camera, Camera Assisted Part Nesting and many other Intelligent Functions. The Nozzle Centering camera provides visibility of nozzle location while adjustments are made on the torch. Camera Assisted Part Nesting automatically determines the arrangement of parts for cutting on remnant material. Intelligent Setup, Monitoring, and Cutting Functions support optimal laser-cutting performance.

Subscribe to learn the latest in manufacturing.