Start Cutting Sooner with Quick and Hassle-Free Tools

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Posted: February 13, 2023

Cut back on the tooling process with versatile, flexible and innovative designs built into products that result in longer tool life and gains in your shop’s productivity.

Increasing Tool Life with Precision Cooling

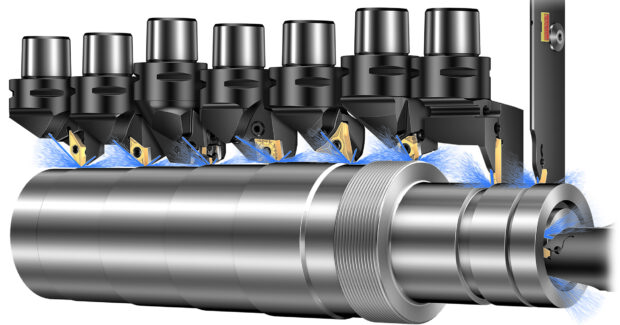

Sandvik Coromant (Mebane, NC) has upgraded its long-standing tool family with precision coolant technology. The Sandvik Coromant’s Coromant Capto® quick change tool holders for the T-Max® P carbide turning insert now include through-tool delivery of precision over and under coolant. Precision coolant is especially advantageous for machining ISO S, M and P workpiece materials. With this addition, the new holders increase tool life and boost productivity.

Operations like steel turning create a high-pressure environment for metal cutting tools. As such, turning tools that feature nozzles to deliver precision coolant to the cutting zone can control chip breaking and offer secure machining. In addition to regulating chip breaking, implementing coolant controls tool temperature for a long and predictable tool life, while also offering positive effects on surface quality.

Due to the benefits of using precision coolant, many of Sandvik Coromant’s tools for steel turning applications feature a degree of cooling technology. Now, one of Sandvik Coromant’s most widely used group of turning tools is receiving the upgrade.

T-Max P inserts are specifically designed for high-performance turning in modern production, while the Coromant Capto is a modular, quick-change tooling concept, which offers a large variety of extension and reduction adaptors to support assembling of tools with different lengths and design characteristics. As part of a tooling offering that combines the modular Coromant Capto interface with the T-Max P clamping insert, the Coromant Capto tool holders for the T-Max P come in two designs: the T-Max P lever clamp for turning medium to large components and the T-Max P rigid clamp, designed to deliver maximum operational security.

The Coromant Capto tool holders for the T-Max P benefit from precision over and under coolant, meaning coolant is delivered to both the rake and flank side of the tool. This feature is designed to reduce its operating temperature.

Because pre-directed precision over coolant can improve chip formation and increase the process window where no operator is needed, this method can be used to improve the efficiency of unmanned machining. This ensures the process can be carried out with greater reliability, which in turn can reduce operator costs.

Integrated under coolant also has the potential to improve tool life by up to 20%. The benefit of under coolant becomes even greater with increased heat generation, improving component costs and reducing tool cost per part.

The Coromant Capto tool holders for the T-Max P encompasses Sandvik Coromant’s largest group of turning tools, providing tool holders for the most commonly used turning inserts.

Flexible Changing System Now Offered for Live Tools

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, now offers its popular u-tec® flexible changing system on all live tools in the company’s product line. Tools are now available for the most popular machine tool models in the market, said Platinum Tooling Technologies, Inc.’s (Prospect Heights, IL) President Preben Hansen. Platinum Tooling is the exclusive North American importer. Heimatec plans to include its u-tec flexible changing system on all live tools and angle heads, going forward, Hansen said. This design offers the benefits of quick change, while maintaining exceptional rigidity.

The u-tec patented changing system allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe or mill, using a single tool, without having to commit to a quick-change system on the initial purchase. A face mill adapter, for example, can be quickly positioned into the standard holder, without the need for a new tool purchase. This significantly reduces inventory costs as well as changeover time for the busy shop.

The u-tec system, Hansen said, “…represents a real improvement in lathe live tooling design. U-tec allows great user flexibility and ensures a solid connection due to the polygon design built into both the tool and the adapter. This polygon connection helps guarantee the proper position and alignment of the adapter inside the tool. Once the insert is properly positioned and the collet nut is clamped, the cutting tool will have excellent rigidity and torque transmission.”

The unique collet nuts on the u-tec system have internal threading for clamping stability and this new tool adapter system enables the actual cutting tool to be brought into proximity to the bearing, thus further improving performance in use.

Every adapter in the u-tec system is furnished complete with the necessary clamping nut and holding wrench. U-tec adapters are available in various outputs such as arbor, Weldon, ER extension and blank styles.

The u-tec system is available for all major turning machines on the market today. Heimatec currently manufactures more than 10,000 live tool types and has a full inventory at Platinum Tooling.

Hydraulic Chucks and Reduction Sleeves Take the Hassle Out of Tool Holding

Manufacturers must overcome specific machining challenges cost effectively. With this goal in mind, Seco Tools LLC (Troy, MI) offers its comprehensive range of hydraulic chucks and accompanying reduction sleeves in three versions, each able to accommodate several tool shank size variations for reduced tooling inventory. With 360° tool-shank holding strength and precise centering, the hydraulic chucks and expansion sleeves ensure reliability, along with exceptional machining performance and maximized tool life.

For simple, easy-to-use, versatile tool holding, the three versions of Seco Hydraulic Chucks include the HC Conventional, HCR Reinforced and the HCS Slim. The HC Conventional version delivers precision holding for drilling, reaming and light milling. As a universal solution, the HCR Reinforced version provides effective holding for all applications from HSM to HPM and for all kinds of tool shank types like Cylindrical, Weldon and Whistle Notch. The HCS Slim holder version is ideal for accessing deep, narrow part cavities during 5-axis machining at high speeds.

“Complicated tool holding systems not only require special care and training to avoid operator injury, they add extra time and costs,” said Seco Product Manager Yves Heitz. “Seco Hydraulic Chucks and Reduction Sleeves eliminate the risk as well as any extra maintenance to allow users to get in the cut faster while gaining tool holding versatility with less required tooling.”

For added flexibility to accommodate a wide range of cutting tool sizes, 05FHC slotted Reduction Sleeves for the Hydraulic Chucks allow one holder to handle various shank diameters. They provide through-tool or peripheral cooling capabilities and work with either metric or inch-size tools.

According to Heitz, at high spindle speeds, controlling tool holder runout is imperative. When machining at speeds up to 25,000 rpm for example, Seco Hydraulic Chucks and Expansion Sleeves minimize runout and the vibration it causes. Users gain worry-free tool holding without the added cost of specialty holders.

To keep vibration under control, Seco Hydraulic Chucks incorporate internal reservoirs in which oil generates strong 360° tool clamping forces and acts as a natural vibration dampening system – engaged with the simple turn of a hex screw. Additionally, reduction sleeves compress uniformly and completely around tool shanks for precise centering and holding strength.

The slotted reduction sleeves come in sealed and peripherical coolant versions, and the hydraulic chucks support all Seco round tools. The holders are compatible with all common machine tool spindle interfaces, including HSK, DIN, BT, BT Taper/face, CAT, CAT Taper/face and cylindrical straight shanks. Metric shank tools clamp directly in chuck IDs, while inch shanks are held through use of the reduction sleeves.

Subscribe to learn the latest in manufacturing.