Next Level Sawing

Breakthroughs in the development of robust sawing systems ensures your shop will exceed your customers’ most challenging and unique demands.

Posted: February 16, 2023

The latest cost effective sawing systems and band saw blades provide precise and accurate cuts thanks to their durability and the power to cut through the toughest materials out there. Carbide band saw blades last longer, resulting in lower operating costs. Learn what the latest technological advancements can mean to your operation.

Richard Childress Racing Reaps Major Benefits from Band Saws

For Richard Childress Racing’s (Welcome, N.C.) manufacturing department, a move in recent years to a mix of parts manufactured for industries outside of the racing industry meant utilizing advanced machinery, such as CNC machines with high levels of automation, as well as carbide band saw blades. The manufacturing department turned to WIKUS Saw Technology Corp.’s (Addison, IL) products to ensure a substantial increase in blade life, and accurate, precise cuts that would deliver a high level of precision, and a quick, quality turnaround.

Richard Childress Racing’s manufacturing division is comprised of a mix of 60-to-70% contract work for industries such as the military, aerospace and defense; and 30-to-40% race industry related manufacturing, including the company’s engine department, which leases motors to other race teams.

The company won the contract from NASCAR as the single source supplier of all the single lug nuts used by NASCAR teams. This lug nut is a single, centering lug nut for the wheels, as opposed to the five lug nuts that have been used on wheels for decades. The move to a single lug nut is expected to further decrease the time spent in pit stops by drivers. Which is where WIKUS’ band saw blades prove crucial to Richard Childress Racing’s manufacturing processes.

Rocky Helms, vice president of manufacturing for Richard Childress Racing, said the metal material to manufacture the single lug nut is tough and hard to cut. “We have to have a really accurate cut on it because we are generating so many of them,” Helms said. “We use a robot for the loading mechanism so the blanks can’t vary in length.”

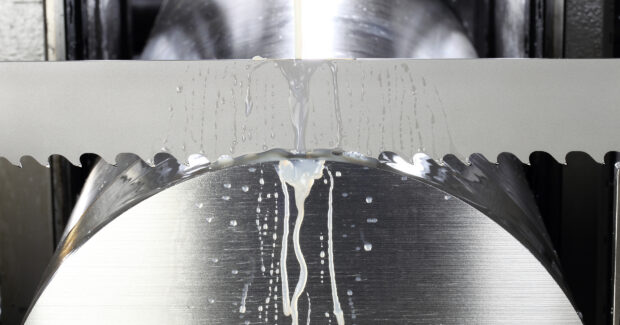

Richard Childress Racing uses WIKUS’ FUTURA® carbide tip band saw blades and the MARATHON® M42 blades in their processes. On modern carbide-suitable band sawing machines, the FUTURA unleashes its full potential, especially for multiple cuts on structural, case-hardened, tempering and carbon steels.

The MARATHON M42 offers flexibility in applications thanks to the expansion of the product line. They are available for small cross-sections up to large solid materials. The superfinishing of this band saw blade and the sharp cutting edges increase blade life and improve the quality of the cut.

Helms noted that Richard Childress Racing cuts thousands of the single lug nuts in a year. “It is a complex part, so it takes a while to machine one of them,” Helms said. That is why it is so important to get more parts and cuts from the band saw blades, as well as benefit from the accuracy and straighter cuts of the blades.

The WIKUS blades are readily available to source for Helms and his team, and they have proven to be more cost efficient compared to other blades. “The biggest thing we see is a big increase in blade life,” Helms said. What’s more, customer service from WIKUS is outstanding, Helms noted. WIKUS representative, Randy Goss, ensures Richard Childress Racing is getting the most it can out of its WIKUS saw blades. Goss provides options for Helms to try, as well as points out applications that might benefit from a different type of blade.

Helms summed up his experiences with WIKUS’ band saw blades: “The longevity of the blades is better and it has brought our operating costs down from the saw and materials side.”

Technology Improves Sawing

Most often when the topic of increasing rates of production involving sawing operations is discussed the immediate response is to evaluate specific saw parameters, items like blade selection, saw arm feed rates, blade speeds or employee performance. While all of these factors should be considered it is sometimes an issue that exists elsewhere in the sawing process that can make the greatest impact.

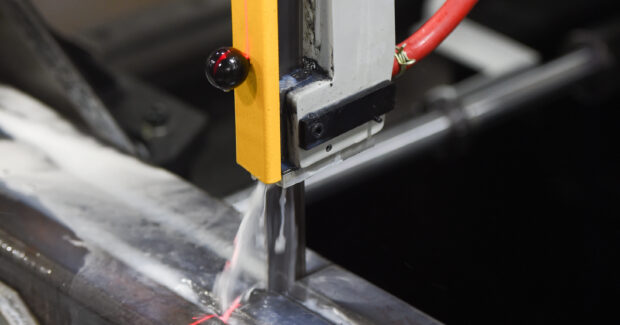

At HE&M Saw (Pryor, OK), updating saws with newly developed and more technologically advanced equipment will most definitely increase efficiency in sawing operations. Innovations such as HE&M Saw’s Blade Enhancer® feature, the introduction of Industry 4.0 concepts, and the evolved manufacturing standard of MTConnect® in newer control systems have improved saw operations as well as overall performance evaluation and maintenance coordination. The updated Cut Watcher® feature, called Active “Cut Watcher”®, not only monitors the straightness of the cutting but also takes steps to correct it.

HE&M Saw’s new and enhanced Smart Saw® controls and Smart Saw Connect® improve process flow and interaction with the equipment with software that will be compatible with MTConnect, the non-proprietary manufacturing technical standard designed so that data can be exchanged between software applications and equipment on the shop floor. HE&M Saw has supported the compatibility because MTConnect is designed to allow all machine tools to speak a common language for the purpose of visualizing efficiency and data. MTConnect is becoming the standard for shops in the United States for all CNC machines.

With efforts geared around designing and manufacturing equipment that will last longer, perform more efficiently and be more productive, the new technological advances will provide a much faster ROI for customers while saving time and increasing productivity.

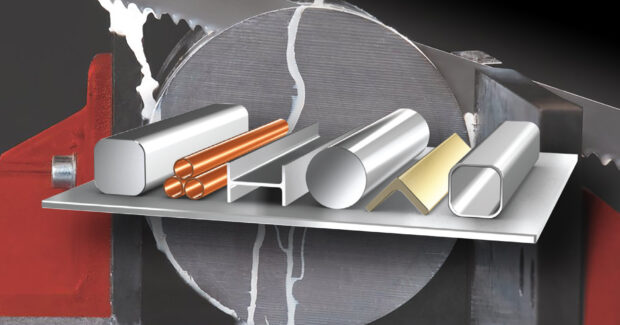

Multi-purpose Band Saw Blades Cut a Wide Range of Materials and Shapes

The L.S. Starrett Co. (Athol, MA) offers IntenssTM Bi-Metal Band Saw Blades for general purpose metal sawing of a wide range of materials and shapes. Featuring a patented process developed by Starrett called bi-metal unique® technology, which provides 170% more weld contact with the teeth, Intenss blades exhibit superior resistance to tooth strippage, significantly reducing fracture and breakage, which enables exceptionally long blade life. Performance is further enhanced by M42 teeth with a multi-edge tooth design that produces split chips for faster cutting.

Starrett Intenss Bi-Metal Band Saw Blades are available in 1/2″, 3/4″ and 1″ widths and .025″ and .035″ thicknesses, featuring bi-metal unique. Blades in 1-1/4″ or 1-1/2″ widths and .035″ and .042″ thicknesses are also available, without the bi-metal unique feature. Intenss blades are offered in pitches of 10, 14 or 18, and 2-3, 3-4, 4-6 and 5-8 variable pitches. Coil lengths are available in 100′ (30 m), 150′ (45 m) or 250′ (75 m), depending on blade widths.

Manual, Vertical Tilt-Frame Band Saw Provides Cost-effective Solutions

The Cosen Saws North America (Charlotte, NC) V-1822 Vertical Tilt-Frame Band Saw is a new addition to the company’s extensive product line. In an ever changing and growing fabrication market, the need for cost-effective cutting solutions at different capacities and price points is evident. With vertical saw designs becoming more popular among fabricators, the V-1822 takes Cosen’s popular tilt-frame design and applies it to a rigid, yet small, footprint with an 18″-x-22″ capacity.

Developed to be a more affordable option for those in non-production settings, the saw is a manual design and allows for miter cuts ranging from 0-to-60°, both left to right. The saw comes equipped with a 1-1/4″ blade, a 5 hp blade motor, and comes standard with an adjustable 0-to-5° blade cant to help increase blade life and provide efficient cuts.

Other features include:

- Gearbox designed to accept high lateral pressure

- Adjustable flood coolant system

- Powered wire blade brush

- Carbide blade guides and guide bearings provide additional blade support

- Rigid cast-iron guide arm and bed design

- Manual blade tension device with pressure gauge

- Retractable coolant tray for easy access

- Built in table t-slots

- Wash down hose for easy cleaning

- Quick clamp and release movable and fixed vises for optimum workholding and operation efficiency

- Easy, one-person blade change

New Large Capacity Automatic Upcut Circular Cold Saw

Scotchman Industries (Philip, SD) introduces the GAA-600-90 CNC, Automatic Upcut Circular Cold Saw, the newest addition to the company’s non-ferrous saw line. The GAA-600-90 CNC is a large capacity upcut automatic saw with a 600 mm (24″) diameter carbide blade for cutting non-ferrous materials at 90° up to 8″ square or round and 14”-x-4” rectangle.

The precision CNC control stores 10 programs, with each program containing up to 30 different cut lengths and quantities, which can easily be created or adjusted right on the machine at any time. Programs can also be imported through USB port.

The saw uses a robust shuttle feed design featuring a 27” ball screw servomotor automatic feeder. Adjustable length selector from 0.200″-to-20″ and unlimited stroke and adjustable cutting and feeding speeds provides more versatility to customize the saw’s operation to fit specific requirements. Three horizontal and three vertical pneumatic clamps secure the workpiece during the cutting process assuring the highest cut length tolerances, ± 0.0006″ per index.

The saw’s standard features include: a 7.5 hp motor that delivers a cutting speed of 3,000 rpm; pneumatic mist coolant system; powered hood lift and LED lighting; a base designed with two chip extraction ports makes it easy to couple with a chip vacuum; meets CE standards, 230 volt or 460 volt configurations; and is backed by Scotchman Industries’ two-year warranty on parts.

Powerful, Accurate and Reliable High Production Saw

Behringer Saws, Inc.’s (Morgantown, PA) HBE-320/523GA is a state-of-the-art, dual-column, horizontal band saw. With its standard Industrial PC operator’s control, it automatically positions both the material length and required miter rotation with high precision. The PC controls also allow for a wide range of programming, functionality, customer information, and virtually unlimited program storage.

With its heavy duty dual-column design and ball screw servo driven technology, the HBE-320/523GA delivers the industry benchmark regarding both length and miter angle tolerances, and repeatability. Length tolerances are +/- .005” or better, and with a miter accuracy of 1/10th of 1 degree, it is truly a precision sawing operation.

Built with Behringer’s renowned cast iron construction, this machine is very rigid, assuring square and fast cutting performance. The inherent vibration dampening characteristics of the cast iron components also ensures a high-quality finish and long blade life. The independently powered chip brush, precise blade lubricant application, and high blade tension due to the dual-column design, help the HBE-320/523GA generate excellent chip evacuation, cut quality and squareness.

The HBE-320/523GA has cutting capacities of 20.4” (520 mm) wide by 12.6” (320 mm) high, and miter capacity of 45° right and 60° left (105° total rotation). It also has special miter cutting capabilities such as the ability to do double miter cuts on each end. The standard automatic downfeed pressure regulator ensures the optimal in blade chip load, and by self-monitoring the feed rate, it delivers long blade life and precision.

Behringer Saws also supplements machines with any material handling requirements you may have, including non-powered or powered roller conveyors, loading magazines, output sorting units, and many other optional components. The ability to automate saw operations allows for the greatest possible efficiency and even “lights out” operation.

Finally, like all Behringer Saws, the HBE-320/523GA is supported with outstanding post sale support, including initial machine start up and training, by the company’s team of factory trained field service engineers. In addition, the Behringer Parts Department in Morgantown is well positioned with inventory to supply consumable and replacement part needs over the long lifetime of the saw.

Automatic Vertical Band Saw’s Unique Blade Chamber Prevents Snagging

The new V-18APC-60-120 from HYDMECH USA (Conway, AR) is an automatic vertical band saw that is a versatile and user-friendly cutting solution. With its 10′ rack and pinion bar feed and standard safety guarding, it’s able to cut bundles of material easily and safely with the banding left on.

One of the standout features of the V-18APC-60-120 is its unique blade chamber, which prevents the blade from snagging by providing a path for it to retract through after completing a cut. This ensures smooth and efficient operation, making it perfect for high-volume cutting applications.

The saw also features an 8.5″ Mitsubishi FX3U PLC color touch screen controller, which is intuitive and easy to use. Its interactive interface and user-friendly graphical icon programming make it a breeze to setup miter cuts and manage up to 1,000 jobs, with the ability to queue up to 20 jobs at a time.

Subscribe to learn the latest in manufacturing.