High Level Resistance Welders Deliver High Levels of Productivity

Metal fabricators will find no shortage of advanced and readily available resistance welders to meet their needs.

Posted: February 14, 2023

Top-tier companies manufacture a variety of resistance welding capabilities in their product lines that provide optimal performance, versatility and short cycle times, and numerous other advantages.

Pedestal-Style Resistance Welder Combines Versatility and Small Footprint

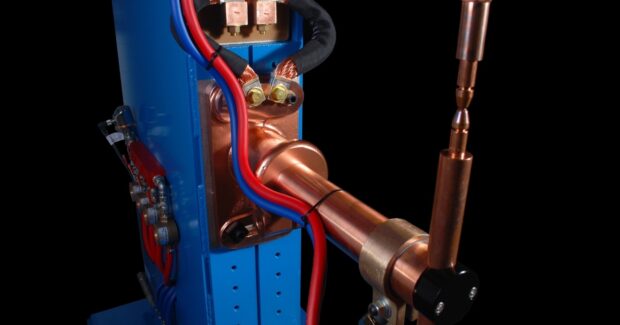

Do you want a resistance welder that combines versatility, quick delivery, competitive pricing and a small footprint? Look no further than T. J. Snow Co.’s (Chattanooga, TN) SlimLine pedestal-type resistance welding machines.

Available as a resistance spot or projection welder, T.J. Snow’s popular SlimLine design is typically configured with a round copper lower arm and a single vertical-acting welding gun producing 1,680 pounds of weld forging force. When an optional flat copper tooling plate and a fabricated lower platen is specified, special fixturing can easily be installed.

The ultimate SlimLine is a combination spot and projection welder with a quill-type ram, T-slotted platens and spot-welding arms with ejector-type electrode holders. Another option is a reinforced upper crown fabrication that can accommodate multiple weld guns.

T.J. Snow’s SlimLine ped welders are very popular for nut and stud welding applications, whether manually loaded or equipped with an automated feeder. Also, the machines are often paired with a robot that holds and manipulates the fabrication as it is being welded.

Available safety features include the choice of a shrouded foot switch, dual palm buttons, light curtains and/or a complete plexiglass or wire mesh enclosure. In addition, the Soft Touch pinch-point system is a popular option.

Single phase RoMan AC welding transformers are standard, and three-phase inverter-type Mid Frequency Direct Current (MFDC) power supplies are available.

Various brands and models of welding controls from Entron and WTC are available from stock.

Having SlimLine components readily available from stock means that the machines are usually available quickly. If fact, as time permits, standard SlimLines are assembled and added to the company’s Fast Ship line for delivery on short notice.

New, Ready to Ship Resistance Welders

Taylor-Winfield Technologies (Youngstown, OH) now offers a full line of ready to ship, economically priced resistance welders. The Essential Series offers many configurations for spot/projection, seam, rocker arm and flash butt welding. They are a cost packaged off-the-shelf, economically priced option for resistance welding sheet metal and other parts production. With short lead times at an affordable price, the Essential Series resistance welders are designed to get the job done with minimal investment.

Taylor-Winfield will also continue to offer the legacy Signature Series line of resistance welders that have proven their worth for decades. Options for customizing the Signature Series of welders for specific applications include throat length, welder configurations, transformer size, control options, cylinder size, welder stroke, platen size, fast follow-up, custom tooling, ram configurations, robotic integration and more. If high production output with minimal downtime is important, Taylor-Winfield has the welding solution to meet your needs.

Inverter Resistance Welding Power Supply Achieves Optimal System Integration and Optimum Feedback

AMADA WELD TECH EUROPE’s (Puchheim, Germany) IS-Q Series Inverter Resistance Welding Power Supply features a compact design for optimal system integration. The IS-Q series is designed to be used in combination with mechanical, pneumatical, or motorized weld heads. This technology is ideal for a variety of applications, including stranded wire to coil, motor fusing, and stranded wire to terminal welds.

The IS-Q series offers control monitoring with both MG3 and the OP-AWS3-A Active Welding Systems. The OP-AWS3-A integrates the process control of all mechanical and electrical parameters. It also integrates static and dynamic process monitoring, as well as quality analysis with an advanced SPC feature and data logging capability.

The integrated process monitoring offered by this series allows for rigorous quality control. With a high output current, the system also leads to short cycle times. With up to 20kHz of feedback, it enables fast reaction to fluctuations in the weld process. Indeed, optimum feedback is achieved due to the series’ current, voltage, and power mode controls. The IS-Q Series also offers additional force control via a proportional pneumatic valve.

The series comes in a variety of different versions, each with a different performance range, weld current type, as well as various other features. These versions include the IS-Q3000A, the IS-Q6000A, the IS-Q40A, and the IS-Q500A.

Subscribe to learn the latest in manufacturing.