CERATIZIT USA Delivers Maximum Productivity and Cost Effectiveness

CERATIZIT USA Inc. is making quite a name for itself in the United States thanks to its expansive cutting tool portfolio and cutting-edge application engineering support.

Posted: February 12, 2023

SUPPLIER PROFILE

CERATIZIT USA Inc. (Schaumburg, IL) may just be the hidden tooling innovations gem the U.S. metalworking industry has yet to encounter. That lack of familiarity is increasingly fading away as the company proves its mettle by providing leading tooling solutions, specialized engineering services, and delivering its products to shops on time.

CERATIZIT USA, which launched in 2011, is part of the CERATIZIT Group (Mamer, Luxembourg), which for more than 100 years has been a pioneer in developing cutting tools. CERATIZIT is a high-tech engineering group that specializes in tooling and hard metal technologies. In the United States, the company develops and manufactures highly specialized carbide cutting tools, inserts and rods. It has two manufacturing facilities in the United States, one located in Schaumburg and the other in Sacramento, Calif.

By collaborating with its customers, CERATIZIT is responding to changes in the industry, such as the increases in eMobility related projects, and the exploration of 3D printing technologies for mass production of parts. As a tooling industry veteran of 25 years, Dan Cope, executive vice president of the cutting tools division of CERATIZIT USA, has seen numerous changes and is excited about the increasing use of eMobility applications. “There has been such a drastic change in the production and manufacturing of components in that industry [automotive],” Cope said. “And the cutting tool side has to stay ahead or make sure we are in parallel with them on technology.”

Cope said whether it is stator housings, battery trays, braking systems or other components in electric vehicle production, cutting tool manufacturers need to provide turnkey solutions that enable manufacturers to produce at high levels and keep up with the demands of the industry.

“We are really focused on materials and the complexity of components,” Cope said. While typical engine components are made out of steel and aluminum, eMobility manufacturing also utilizes composites, resins and plastics to machine components.

With the growing use of composite materials to assist in achieving energy efficiency resulting from the mandated light weighting of automobiles, CERATIZIT’s MonsterMill FRP/FRP CR solid-carbide milling cutters with special diamond coating and length-independent compression zones, for example, are ideal for the machining of CFRP and GFRP.

This combination of material, size and complexity makes it much harder to build tools to manufacture components, Cope noted. CERATIZIT’s patent-pending geometry for the MonsterMill delivers compression across the entire cutting length (length-independent compression zone). Advantages of length-independent fiber compression include the unique geometry with regular left and right-hand cuts on each cutting element. Also, the accompanying fiber compression across the entire cutting length results in fibers being cut off cleanly in all directions, without damaging the component.

Cope and his team are also on top of the evolution underway with 3D printing of metal parts, determining the best ways to support manufacturers as they navigate this production process. With 3D printing of parts in its infancy, Cope noted, CERATIZIT is engaged and ready to step in and assist manufacturers regarding the mass production of 3D printed metal parts, and the role of cutting tools in the process, especially once industry standards are established.

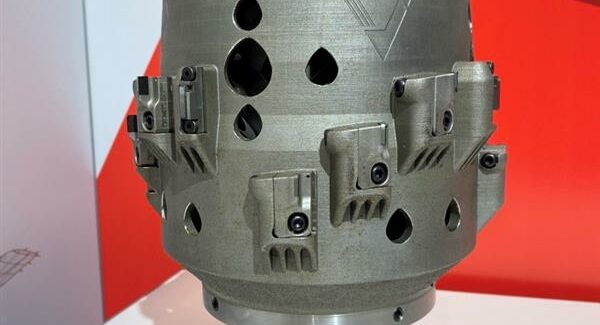

The company is already providing advanced solutions regarding 3D printed parts. At IMTS 2022, CERATIZIT showcased a stator housing for use in electric vehicle motors. The 3D printed, multi-bore tool reduces the number of tools engaged in the part, while also providing the ability to hold the concentricity in the part by utilizing the tool. Cope said the large boring tool has multiple inserts and CERATIZIT built in coolant channels and/or cut the majority of the weight out of the tool thanks to 3D printing as opposed to a traditionally manufactured tool. “If you made that tool from a solid you would not be able to put it into the machine tool because the machine’s tool magazine would not be able to hold it — it would be too heavy,” Cope said.

By developing a one-shot application, end users can not only speed up the process but are also able to manufacture more parts quickly and efficiently, which also showcases the cradle-to-grave capabilities of CERATIZIT’s engineering team. This turnkey solution allows customers to adapt the tool to their equipment and processes, resulting in cost savings.

An Immense Selection of Advanced Solutions

The company provides its customers with access to a vast portfolio of advanced cutting tool and hard metal technology solutions. There are 65,000 SKUs in CERATIZIT’s standard product offering. The products range from indexable milling to solid carbide milling to turning tools featuring FreeTurn technology, also known as high dynamic turning. The FreeTurn tool is a slim, axial structure that offers 360 degrees of freedom in the axis without the risk of collision.

The tool also optimizes chip breakage and improves component quality by changing position during the process. Undercut or contours, which require an additional tool, can be produced with this one tool. Using one tool to rough, finish, contour turn, face or longitudinal turn results in savings in both tool costs and changeover times. Cope said the U-axis actuating head enables the production of complex products on just one machine, speeding up the process.

Applications that benefit from this tool include ball joints, artificial hip joints, and other types of spherical applications.

CERATIZIT also offers a full array of indexable drills, reaming and boring tools, and engineered solutions thanks to the acquisition of Komet in 2017. The company offers the WTX-HFDS, a four-flute solid carbide drill to customers, and is one of the few companies to offer such a product in the market. Instead of using the traditional method and drill with two flutes, coolant channels have been created to the tip of the tool itself. “And on top of that, we utilized our Dragonskin coating technology to build lubricity into the coating,” Cope said. “So, it not only gives you a better penetration rate with the extra flutes but also better tool life through the Dragonskin technology.”

The Dragonskin multi-layer tool coating is based on nanolayers, consisting of a combination of different coating systems and coating technologies. The coating provides maximum protection against external influences and reduces premature tool wear. The chemical compositions create temperature resistance to reduce thermal shocks, allowing for high-cutting speeds when machining high alloy steels.

Dragonskin coating improves the performance and wear resistance of CERATIZIT’s tools, including the EcoCut solid-carbide and insert tools, which increases productivity in four machining processes: drilling, stationary or rotating tools or for turning face, inner and outer contours. The EcoCut Classic, Mini and ProfileMaster versions address various diameters and bores in steel, stainless steel and high-temperature materials.

The Dragonskin coating is also applied to CERATIZIT’s CTPX710 and CTPX715 multi-application grades. The gold-colored TiN outer layer of the Dragonskin multilayer CVD Ti(C,N)/Al2O3/TiN coating acts as an indicator to identify insert wear and index before a breakage. What’s more, sharp cutting edges are kept from going unused and the insert being inadvertently discarded. These grades offer high-performance substrates and advanced coating structures to support high-cutting speeds and increased process security when machining different materials.

In addition to multi-application grades in the form of indexable inserts for turning tools, more applications for milling, grooving, etc. will follow.

Switching gears from innovative coatings, CERATIZIT also offers innovative Industry 4.0 capabilities, such as the ToolScope for digital monitoring and control of machining operations. This system records a continuous stream of signal data generated by machine tools during production and visualizes the data for machine monitoring and adjustments. Monitoring can prevent overloads and triggers an emergency stop for any impact collisions.

To sum up CERATIZIT’s portfolio: the company has a wide range of core competencies and innovations within its product lines, Cope noted.

Tooling a Sustainable Future

With its European roots, it isn’t a surprise that CERATIZIT is well underway with sustainability initiatives in its manufacturing processes and at its facilities. Recently, the company signed contracts to secure green energy to supply all of its facilities in Europe and up to 95% of its facilities around the world. CERATIZIT’s goal is to be the leader in sustainability for the hard metal and cutting tool industry by 2025. It is also on the way to becoming a net-zero corporation by 2040 (which is 10 years ahead of the Kyoto protocol).

CERATIZIT also aims to achieve 95% circularity in its processes, based on scrap recycling rates on sintered product. CERATIZIT’s green carbide, CT-GS20Y, is a world first technological breakthrough, and results from reclaimed material. Through the recycling process, the company has reduced its CO2 generation by 80 percent.

Cope said CERATIZIT also provides a reconditioning service, where the company reconditions used tools to industry standards and resells them back to customers.

He also noted the “mine to market” capability of CERATIZIT, which both assists with the company’s sustainability and supply chain efforts. The company owns mines and produces semi-finished parts, as well as produces finished goods for the market. “We connect that full cycle by the recycling side,” Cope said. “So, you are pulling raw materials, making a semi-finished good and supplying those rods to either our customers or internally manufacturing finished goods that are going out to the market being used by end users. And we are buying back those end user carbides to recycle and restart the process again. We own the full supply chain when it comes to the carbide side of the business.”

CERATIZIT has also streamlined its supply chain and distribution processes. The company’s global distribution center in Kempten, Bavaria, Germany, supplies the U.S. distribution center in Towanda, Pa. There is an ongoing daily shipment from Germany to the United States, ensuring CERATIZIT can provide products to end users within the next day.

And getting products in the hands of machinists in a timely manner is just one of the many benefits of working with CERATIZIT. The cutting tooling solutions the company provides to its customers assist in overcoming their biggest machining challenges. The engineers at the company devise elaborate tools, such as one-tool solutions, to assist in the management and machining of complex parts and hard to machine components.

Cope said CERATIZIT evaluates every aspect of existing or new processes when collaborating with customers to reduce setup time, increase tool life and increase productivity. The company also conducts cycle time studies to provide tool life expectations and total costs of machining components. The company will also create a base line and solve problems as they relate to existing processes, saving end users time and money. “We have all the aspects of being a leader in the U.S. market, but we just don’t have the brand recognition yet,” Cope noted. “We have the people, the products and the services that we feel can bring the expertise to solve problems for our customers and create the tooling that ultimately will provide a sustainable future.”

Facebook • YouTube • LinkedIn • InstaGram

www.cuttingtools.ceratizit.com

{sidebar}

CERATIZIT Delivers Expert Technical Knowledge

Thanks to its pioneering background in the development and manufacture of exceptional hard material products for cutting tools and wear protection in the metalworking industry, CERATIZIT provides unique knowledge and comprehensive solutions to its customers in a variety of sectors. This is possible thanks to a combination of the company’s innovative solutions and its broad product portfolio. The company develops and manufactures highly specialized carbide cutting tools, inserts and rods.

As an example, in the automotive sector, whether the job involves aluminum wheel machining or the production of brake discs, gear housings, wheel suspensions or electric engines, CERATIZIT supplies cutting tools and machining strategies for every single automotive vehicle component for both powertrain and chassis. The company’s specialized staff works in collaboration with its customers to design the perfect cutting tool solution.

For aerospace shops machining complex components made of fiber composites, aluminum, titanium or super alloys, specially designed tooling and machining solutions can tackle these demanding materials. That includes solutions for carbon-fiber reinforced fuselage skin, all structural components and system solutions for engine components.

In yet another instance, for medical device manufacturers, CERATIZIT also supplies high-quality tools and application support to make certain products such as artificial joints for knees, hips and shoulders, dental implants or bone screws and plates are machined to high standards, so they perform flawlessly.

In another example, regarding bar peeling applications, CERATIZIT’s solutions guarantee high process security, optimum surface quality and maximum machining rates. In addition to tooling, the company guides customers regarding optimization and tips on the challenges and possibilities with bar peeling.

Subscribe to learn the latest in manufacturing.