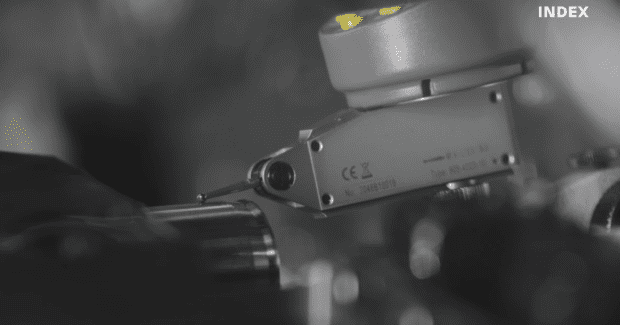

The CenterMaster Accessory Center Aligns Drills on CNC Multi-Spindles

The CenterMaster from INDEX is a system that allows operators with no specialized knowledge or experience to set up a drill in two-to-three minutes. It also provides a repeatable accuracy of <5μm.

Posted: January 16, 2023

As part of the company’s sustained investment in R&D focused on streamlining the setup and changeover process for CNC multi-spindle lathes, CenterMaster reduces the time needed to align a drill by up to 90%.

Previously, center alignment of a drill required specialized knowledge by the operator and a challenging, manual process that could take up to 30 minutes per holder. With CenterMaster, the user simply clamps a radio dial gauge into the workspace and sets it to the quill. The gauge and machine wirelessly communicate, automatically adjusting the holder along the X axis. The system then guides the operator through adjusting the Y axis via the machine’s touchscreen display.

The CenterMaster system allows operators with no specialized knowledge or experience to set up a drill in 2-3 minutes. Additionally, it provides a repeatable accuracy of <5μm.

“Over the past several years, we have introduced multiple innovations to make CNC multi-spindles more flexible,” says Cris Taylor, president & CEO of INDEX. “We had already taken a lot of the time out of setups and changeovers via presetting and our quick clamping system with W-serration locating. CenterMaster eliminates another time-consuming aspect of setups, so that customers can truly optimize their machine utilization.”

Subscribe to learn the latest in manufacturing.