Stress-free and Powerful Turning Delivers High-Quality Parts

Overcome labor and productivity challenges with turning centers and lathes that are created to increase the efficiency of your processes.

Posted: January 17, 2023

Evolutions in the design of turning centers and lathes enhances their speed and accuracy. The power to machine difficult materials reduces cycle times. And quick-change tooling and robotic automation assist in reducing downtime to ensure smooth operations.

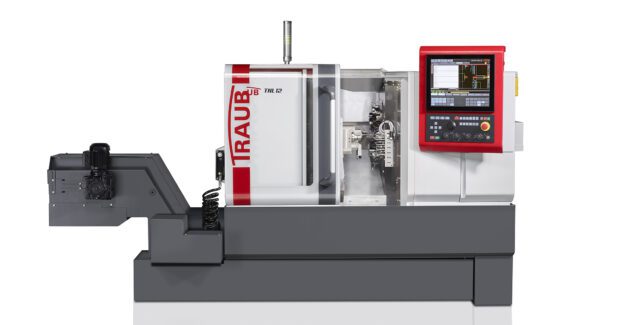

Next Generation Sliding-Headstock CNC Lathes for Small Parts

INDEX (Noblesville, IN), one of the world’s leading providers of CNC turning machines, offers the new TNL12, which incorporates a plethora of design changes that boost speed, flexibility and accuracy.

The machine is well suited for medical manufacturers responsible for producing implants, bone screws and instruments for minimally invasive surgery. It features four tool carriers that can be applied to a workpiece simultaneously, albeit with significant changes to the machine’s kinematics. While the front-working attachment and counter spindle were previously arranged on a single slide, they are now housed on separate slides. This eliminates potential interdependence between front-end and counter spindle machining, allowing for much greater flexibility in programming. Additionally, this design reduces the mass of both elements, allowing for a faster and more dynamic machine response.

The features enabling rear-end machining also have undergone substantial changes. While the former model of the machine offered X-axis machining on the counter spindle, the new TNL12 provides full 3-axis machining in this position.

Overall tooling capacity has also been increased, with the capability to house up to 40 tools with the use of double and triple holders. Each of two 6-station tool turrets has its own servomotor and interpolated Y-axis, with chip-to-chip tool change times reduced to just 0.3 seconds. To maximize the potential for unmanned operation, the TNL12 offers options for automated rinsing, part removal via a small gripper and removal of long parts through the counter spindle. The machine can also be paired with a robot for machining of chucked parts.

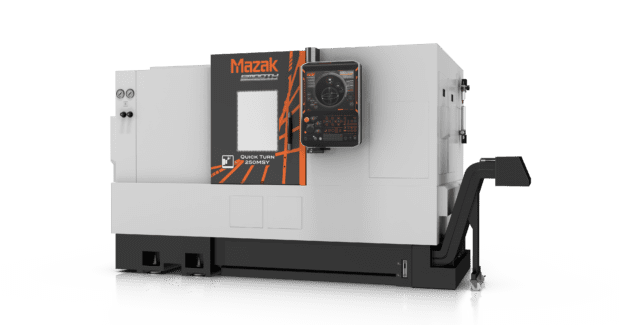

Advanced Turning Center Delivers Productivity and Value

Mazak Corp.’s (Florence, KY) QUICK TURN 250MSY Turning Center delivers outstanding part quality and volume for shops of all sizes. The turning center features two turning spindles, milling capability and Y-axis off-centerline machining. Its main turning spindle headstock incorporates a 10″ chuck mounted on a 35 hp (26 kW) 4,000 rpm integral spindle that generates 343 ft-lbs. (465 Nm) of torque for heavy-duty metal removal.

Available either with a 20″ (500 mm) or a 40″ (1,000 mm) bed, the machine accommodates part diameters up to 14.75″ (380 mm) and bar stock up to 3″ (75 mm). Maximum machining length measures 21.275″ (541 mm) on the 20″ bed and 36.380″ (924 mm) on the 40″ bed.

To position parts accurately for square facing/slotting cuts and precisely drilled holes, the main turning spindle also serves as a full-functioning C axis, programmable in 0.0001° increments. The machine’s 15 hp, 6,000 rpm second spindle with 6″ chuck enables the QUICK TURN 250MSY to transfer parts automatically and perform secondary operations with speed and accuracy.

The machine’s 12-position direct-drive turret improves part surface finishes and reduces maintenance over belt-driven designs and can be configured with either VDI or bolt-on tooling. The turret’s rotary tool spindle delivers 10 hp (7.5 kW), 6,000 rpm and 35 ft-lbs. (47.45 Nm) of torque, or 10,000 rpm with an optional tooling package.

Turning System Optimizes Efficiencies and Alleviates Labor Shortages

Murata Machinery USA, Inc.’s (Charlotte, NC) Muratec MWR120G is an innovative multitasking machine with Y-axis functionality to solve productivity challenges. This automated horizontal lathe is the next generation of the well-known MW series machines with an integrated robotic gantry loader that blends processing capability in a compact body with front-facing twin spindles, live tooling, and Y-axis. The machine’s integrated robotic gantry loader enables unmanned workpiece handling for all-in-one processing of complex shapes from raw to finished parts for maximizing efficiency without changeovers or the need for secondary operations.

“We know that labor shortages remain an ongoing industry problem,” said Jeff Kalmbach, general manager, machine tools division, Murata Machinery. “For manufacturers needing automated turning systems that reduce idle times, optimize efficiencies, increase productivity, and alleviate workforce demands, this new machine is the solution.”

Vertical Lathe Features the Highest Machining Capability in its Class

Okuma America Corp.’s (Charlotte, NC) newest addition to its vertical lathe product line, the VT1000EX, provides new levels of productivity due to its highly rigid mechanical configuration, extreme thrust and torque. This large vertical lathe is ideal for industries looking to dramatically reduce cycle time for difficult-to-cut materials.

The machine weighs 41,800 pounds and features a highly rigid construction and structural reinforcement, all of which enables it to execute stable operations for long operating periods. This lathe includes wide guideway spacing, rigid and precise ball screws for both the X and Z axes, and a heavily cross-ribbed casting, which provides ultimate stability during ultra-heavy cutting of large workpieces.

The VT1000EX’s spindle is capable of a maximum power output of 55 kW, a maximum torque of 5,310 Nm, and a thrust of 30 kN on the X and Z axes. This power and torque make heavy-duty cutting for difficult-to-cut materials possible and can even reduce cycle time by up to 51%.

The VT1000EX also comes standard with a 36-tool magazine for continuous, long-run operation. Tool life is extended by a high-pressure coolant system, and chips are quickly removed with an enlarged chip evacuation system. The machine also minimizes CO2 emissions by reducing power consumption through decreased machining cycle times, shorter Automatic Tool Change exchange times, and the inclusion of an energy-saving control system.

www.okuma.com/products/vt1000ex

Subscribe to learn the latest in manufacturing.