New Solution for In-Line Checking of Pouch Cell Battery Welds

Marposs’ solution can measure thin external plastic layers starting at 1 µm, as well as accommodate thickness variations due to the presence of the tabs in parts of the welding seam.

Posted: January 16, 2023

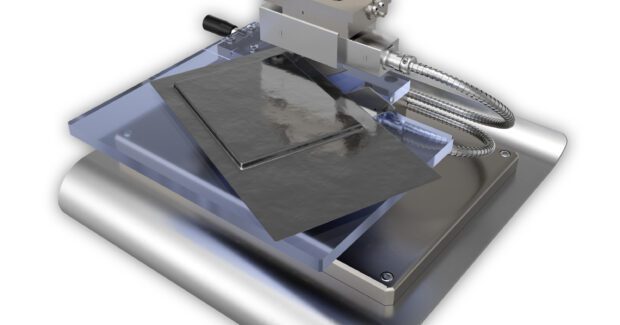

Marposs, a global leader in measurement, inspection and test technologies, has announced its solution for checking the welding joint of pouch cell batteries within the production process. Comprised of interferometric sensors and its NCG (non-contact gauge) controller, the system works by splitting light into two beams that travel different optical paths and are then combined to produce interference, which can identify refractive changes and surface irregularities.

Pouch cell batteries are typically sealed using impulse or contact welding (heat sealing), which fuses the plastic layers together. The thickness of this joint is a key indicator of the quality of the seal and must be measured while the material is still soft. Marposs is able to check this thickness right after the welding process using its non-contact, interferometric technology.

The solution can measure thin external plastic layers starting at 1 µm, as well as accommodate thickness variations due to the presence of the tabs in parts of the welding seam. The pouch cell measuring solution comes with a measuring snap with two interferometric sensors that enable the simultaneous measurement of the total thickness of the welding seam and the thickness of the two external plastic layers. Each sensor has a measuring field of 900/1.8mm and offers a repeatability range within 1 mm of the application thickness.

The basic configuration features the NCG controller, a high-speed elaboration gauge that can be connected to any machine for accurate and fast part thickness control. Optional offerings include a Marposs 9066 industrial PC with Quick SPC software for statistical elaboration and data transfer. Special gauging solutions can be configured to measure the weld thickness in multiple positions, or to fully scan the welding seam along the complete perimeter of the pouch cell.

Subscribe to learn the latest in manufacturing.